A Reconstruction Method of Bending Pipe Model Based on Point Cloud Data

A technology of point cloud data and pipe bending, applied in image data processing, electrical digital data processing, special data processing applications, etc., can solve problems such as insufficient measurement parameters, failure to consider pipeline parameter measurement, inability to apply design and processing, etc. Achieve the effect of reducing the amount of calculation, improving the qualified rate and improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

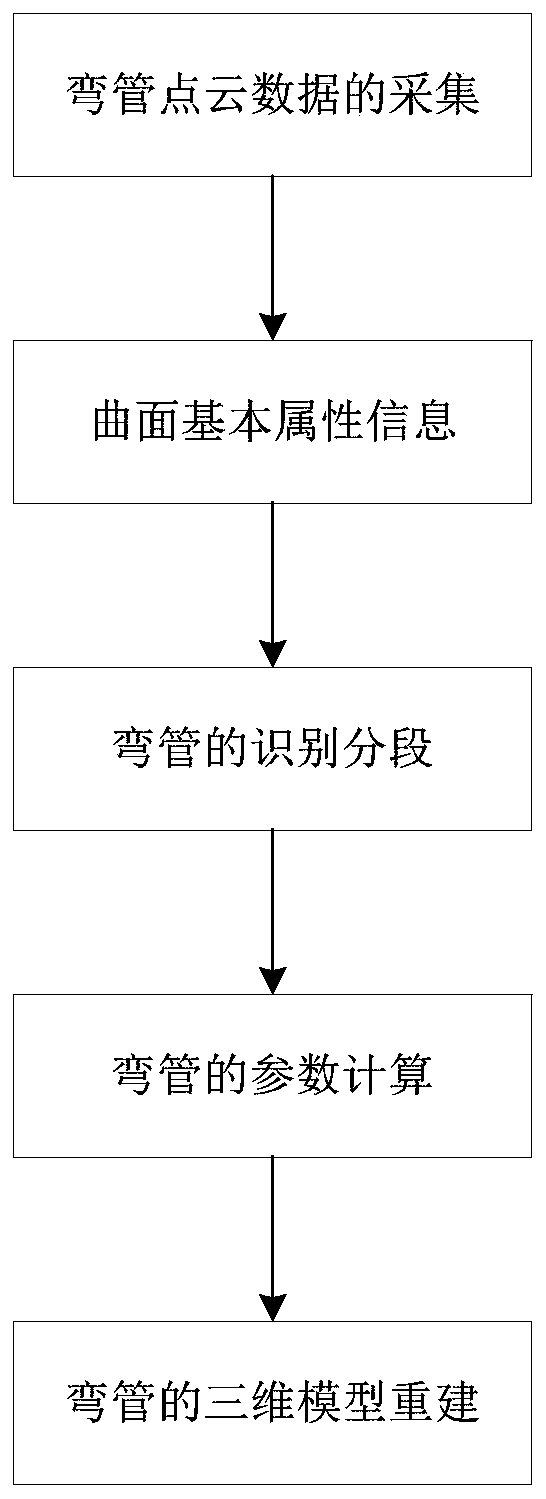

[0062] This embodiment is a reconstruction of an elbow part with only one right-angle bend, including the following steps:

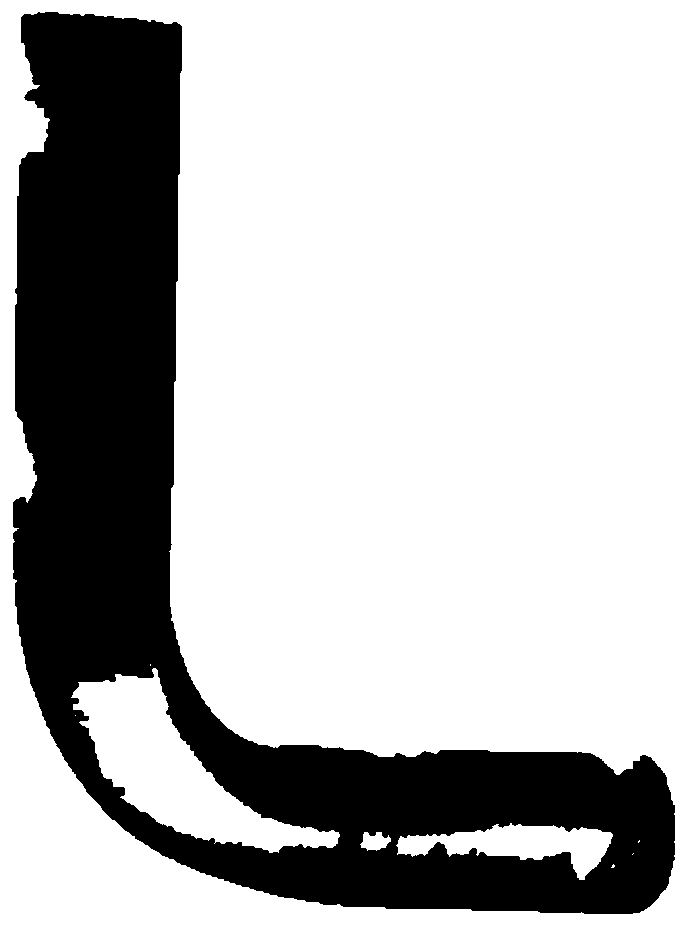

[0063] Step 1: Input elbow point cloud data model

[0064] Such as figure 2 As shown, the present embodiment scans a bent pipe part with a right-angle bend to obtain a point cloud data model M, M={P i |i=1,…,N}, point P i ={x i ,y i ,z i ,i|i=1,...,N}, i is the index of the point, and N represents the total number of points.

[0065] Step 2: Calculate point cloud normal vector, tangent vector and other information

[0066] (2a) First based on the covariance matrix Σ=Q T The eigenvector of Q is calculated for each sampling point P i Handling vector initial value, here

[0067]

[0068] Set the eigenvector corresponding to the minimum eigenvalue of the matrix Σ as P i Handling vector The initial value of ; where (x j ,y j ,z j ) means P j The coordinate value of the point in the global coordinate system, P respectively j neighborho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com