Vacuum cleaner, in particular a hand-held battery cleaner

A technology for vacuum cleaners and base stations, applied in the directions of vacuum cleaners, suction filters, devices for cleaning filters, etc., can solve the problems of impossible regeneration, blockage, hindering regeneration, etc., and achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

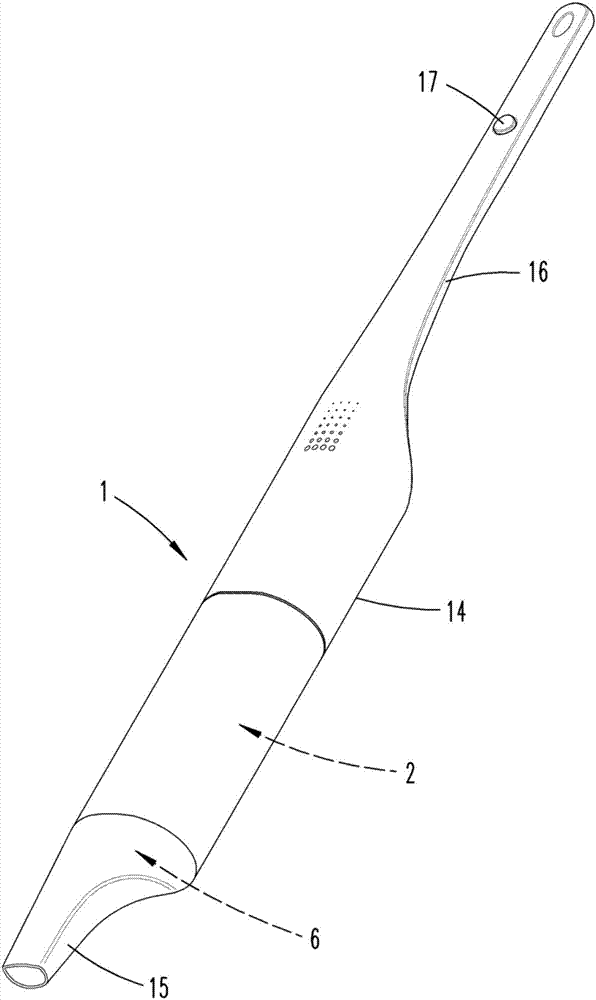

[0025] figure 1 A vacuum cleaner 1 is shown, which is designed here as a battery-operated hand-held vacuum cleaner. The vacuum cleaner 1 has a housing 14 with a filter chamber 2 with an emptying opening 6, a fan 3 (see figure 2 and 3 ) and a handle 16 provided with a switch 17, in this embodiment eg an on key and an off key. In the subregion of the housing 14 with the filter chamber 2 there is a removable suction nozzle 15 which is guided over the surface to be cleaned during the suction operation of the vacuum cleaner 1 . In this case, the dust on the surface to be cleaned is guided through the suction nozzle 15 and the emptying opening 6 into the filter chamber 2 due to the negative pressure generated by the fan 3, in which the dust collects, so that only the The purified air reaches fan 3.

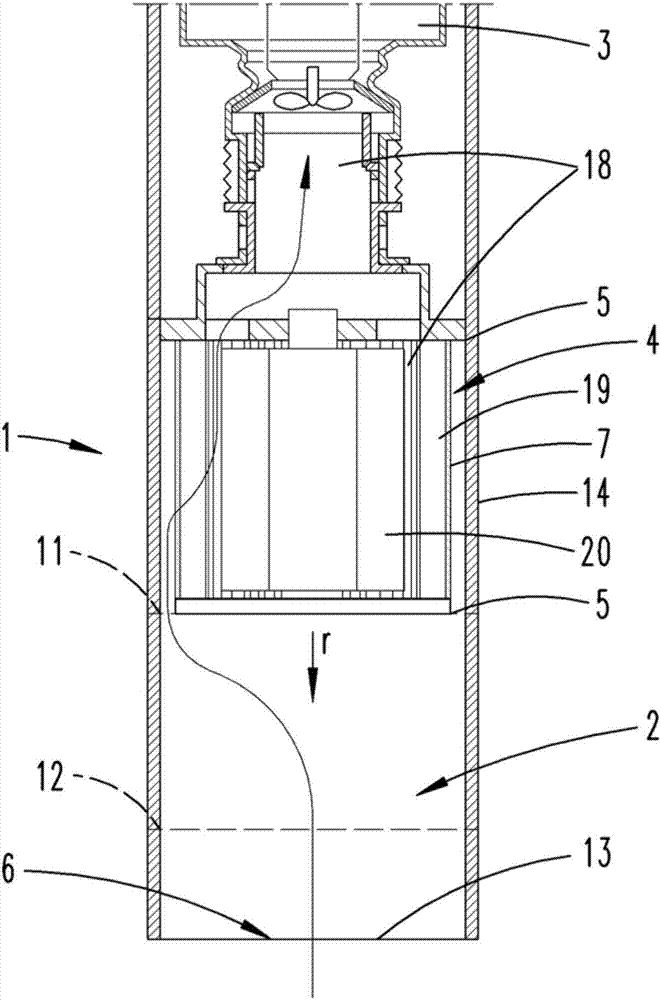

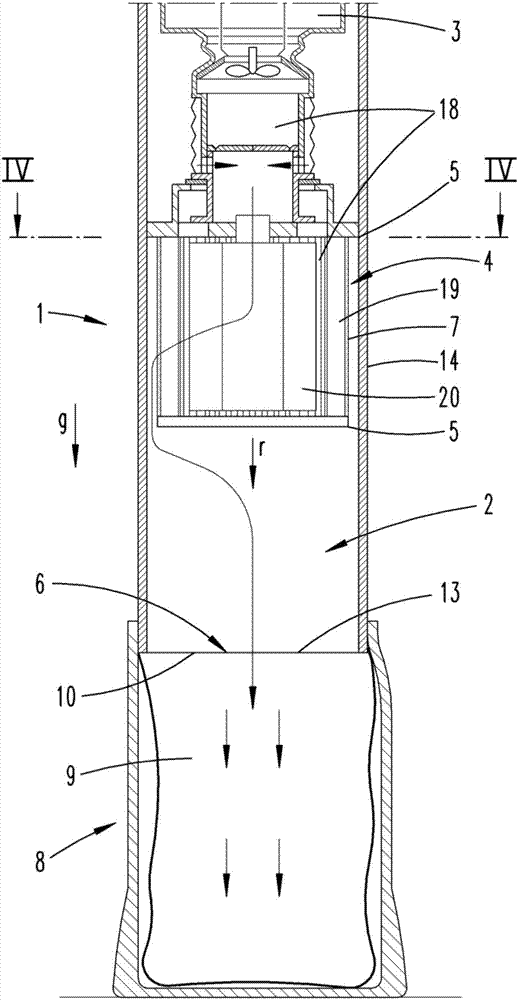

[0026] figure 2 and 3 Shows the longitudinal section of the partial region of the housing 14 with the filter chamber 2 without the base station 8 connected to the filter chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com