Circularly polarized light extraction optical element and method of manufacturing optical element

An optical element, circularly polarized light technology, applied in the direction of optical elements, polarizing elements, optics, etc., can solve the problems of complex process, limitation of binder types, waste of base layer and orientation film, etc., and achieve the effect of suppressing light and dark patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0068] First, through Figures 1 to 10B , Embodiment 1 of the present invention will be described.

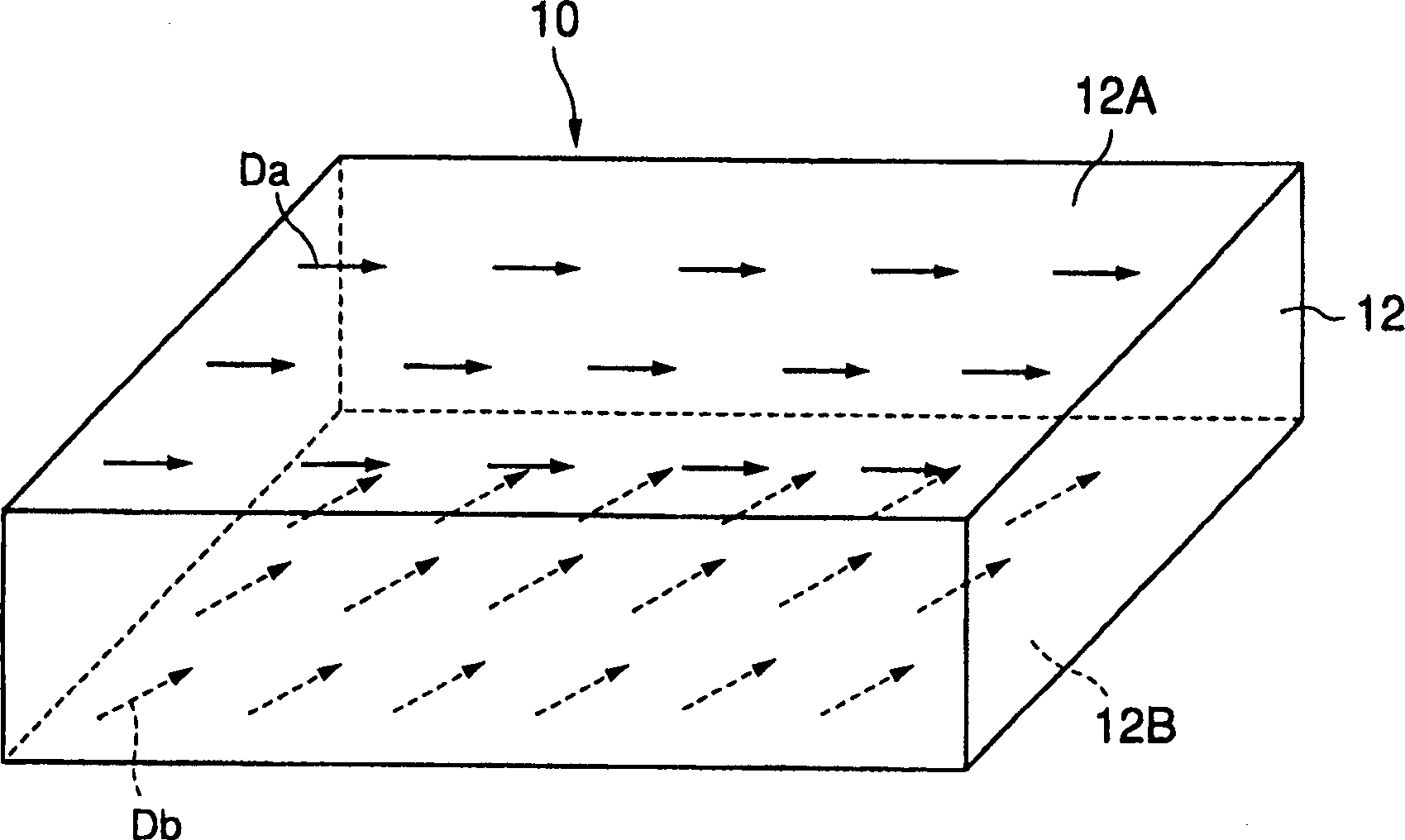

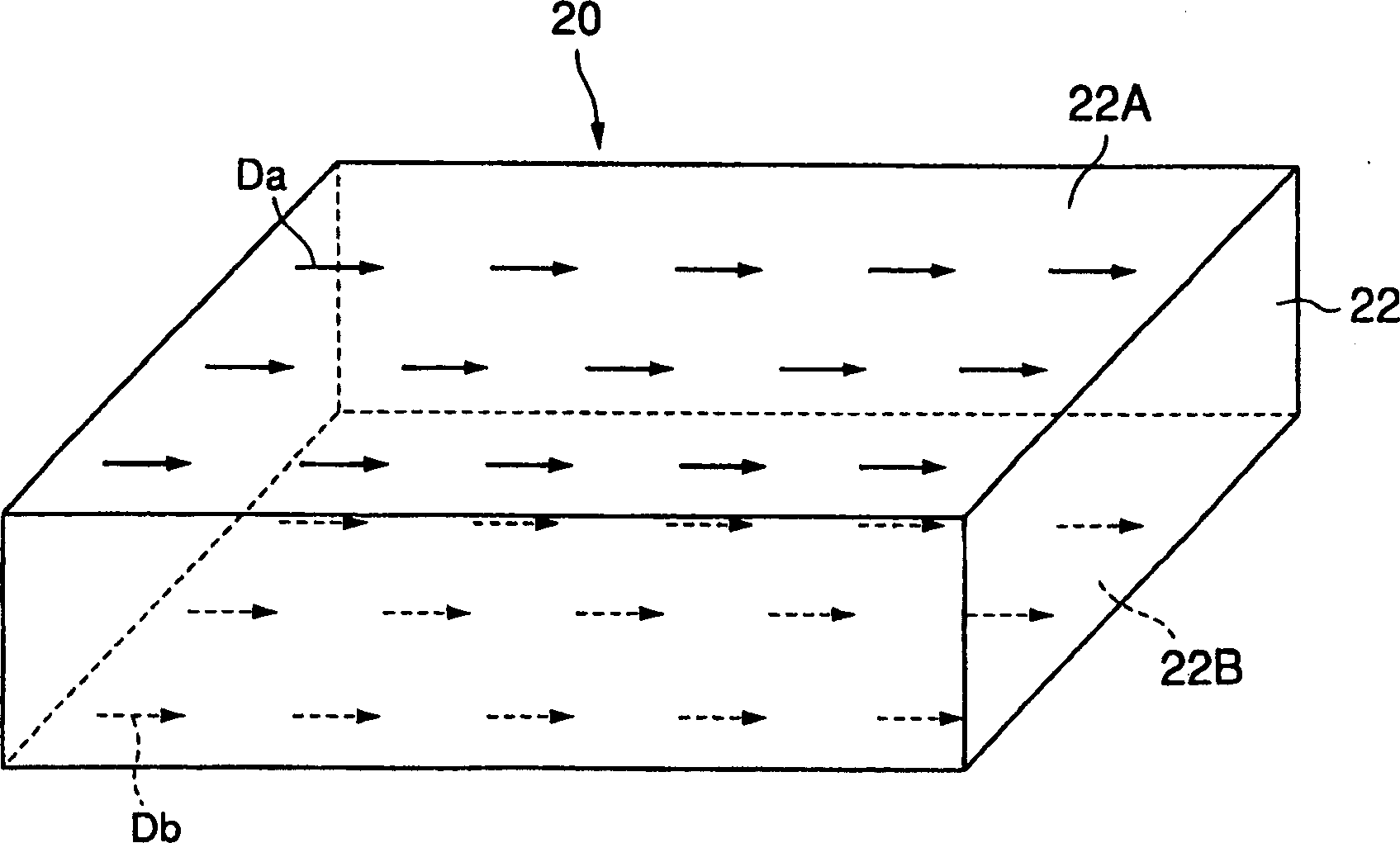

[0069] First, through figure 1 , the circularly polarized light extraction optical element 10 according to the first example of the present embodiment will be described.

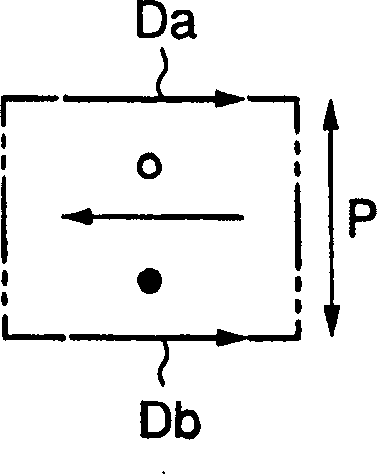

[0070] Such as figure 1 As shown, the optical element 10 for extracting circularly polarized light is equipped with a liquid crystal layer 12 with cholesteric regularity (cholesteric structure) aligned along the plane, and the two opposite main surfaces (larger surfaces) of the liquid crystal layer 12 12A, 12B, the directions of the liquid crystal molecule guiding dipoles Da, Db are substantially the same over the entire range of the respective surfaces 12A, 12B.

[0071] Here, in general, the liquid crystal layer 12 having cholesteric regularity has an optical rotation component (circularly polarized light component) in one direction based on a physical molecular arrangement (planar arrangement) and an ...

Embodiment approach 2

[0133] below, through Figure 11 to Figure 20B , Embodiment 2 of the present invention will be described.

[0134] First, through Figure 11 , the circularly polarized light extraction optical element 110 according to the first example of this embodiment will be described.

[0135] Such as Figure 11 As shown, the optical element 110 for extracting circularly polarized light includes a first liquid crystal layer 112, a second liquid crystal layer 114, and a third liquid crystal layer 116 having cholesteric regularity, and the first to third liquid crystal layers 112, 114, 116 The liquid crystal molecules 118 are stacked directly in order in a state in which the directions of the helical axes 118A of the liquid crystal molecules 118 are substantially aligned (positioned in the thickness direction of the liquid crystal layer). Also, if Figure 11 , Figure 12A and Figure 12B As shown in the model, in the first to third liquid crystal layers 112, 114, and 116, the liquid c...

Embodiment 1

[0202] Next, examples of the first embodiment described above will be described with reference to comparative examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com