Acquiring method of antifatigue grinding process parameter domains of high temperature alloy component

A technology of process parameters and superalloys, applied in the direction of grinding machine parts, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as poor surface integrity, fatigue, etc., achieve accurate relationship model, design and analysis methods reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0051] The invention discloses a method for obtaining an anti-fatigue grinding process parameter domain of a superalloy component, comprising the following steps:

[0052] Step 1. According to the aviation manufacturing engineering manual, experience or literature, establish the grinding process parameter domain C of superalloy components 1 , in this embodiment, the superalloy GH4169DA is taken as an example, the grinding process parameter domain C 1 including wheel speed v s (unit is m / s), member velocity v w (unit is m / min), longitudinal feed a f (unit: mm / r), radial feed a p (in mm), that is, C 1 [v s ,v w ,a f ,a p ], see Table 1 for the specific parameter fields:

[0053]

[0054] Table 1

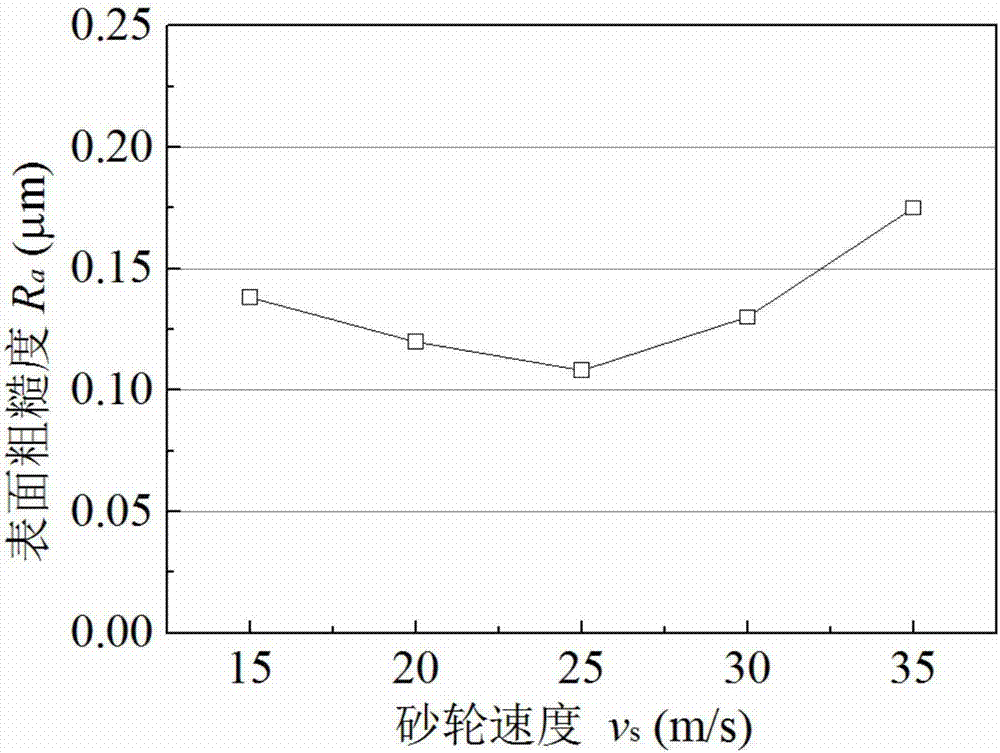

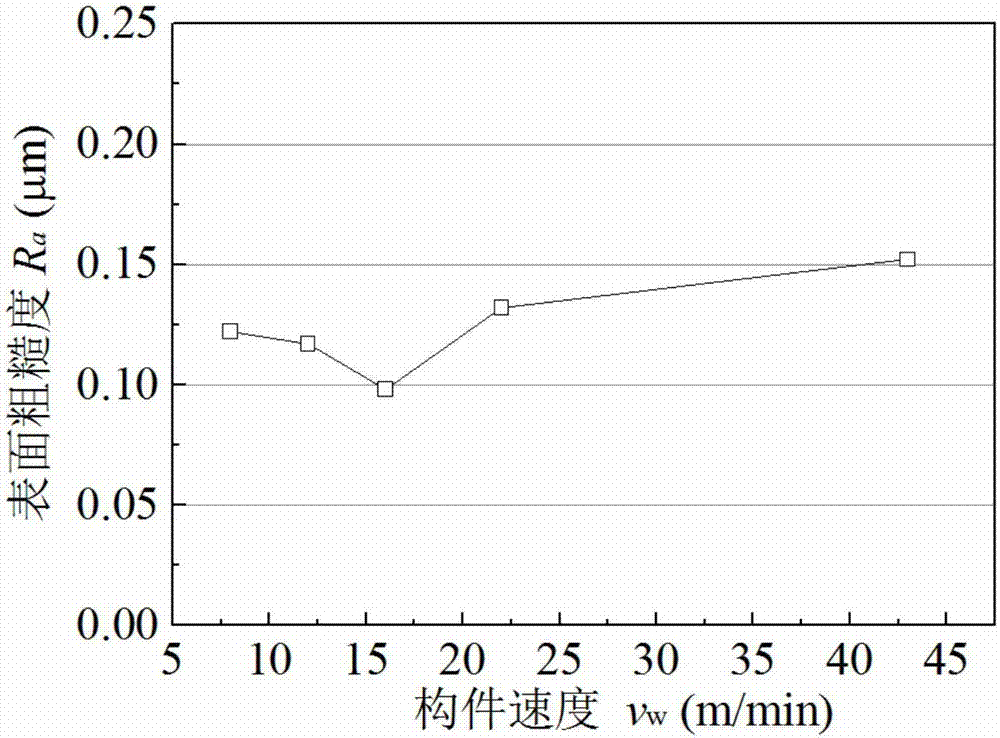

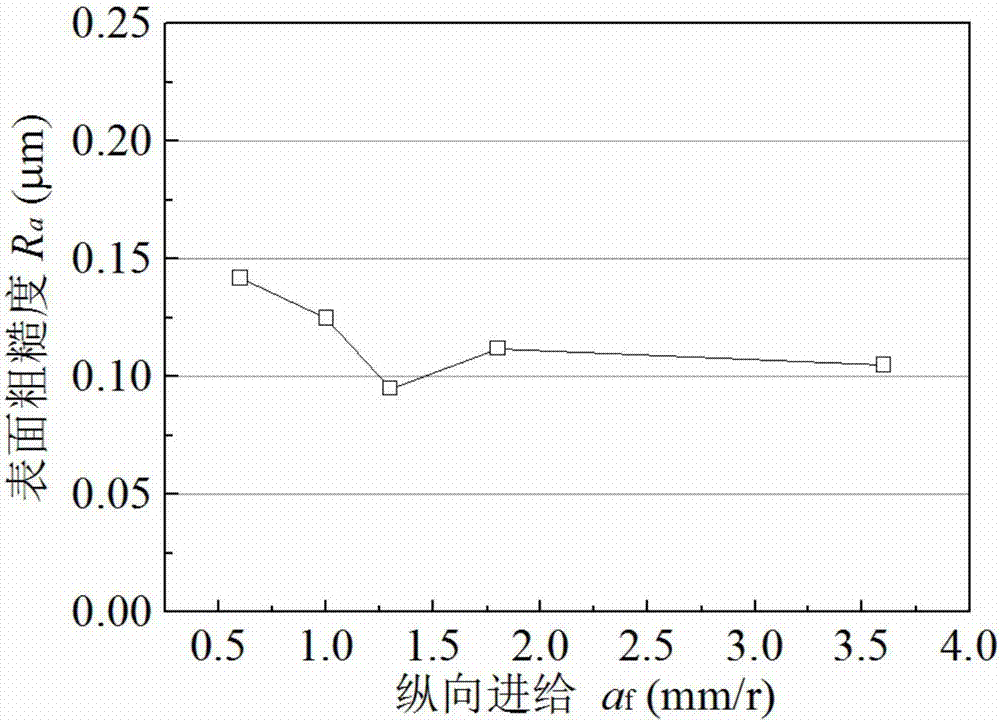

[0055] According to the superalloy GH4169DA component grinding process parameter domain C 1 Carry out single factor test, according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com