Gas stove

A gas furnace and furnace body technology, which is applied in the field of gas furnaces with energy-saving effects, can solve the problems of flameout, lack of fire, and no fire in the furnace, and achieve the effects of ensuring circulation, simplifying the structure, and saving water pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

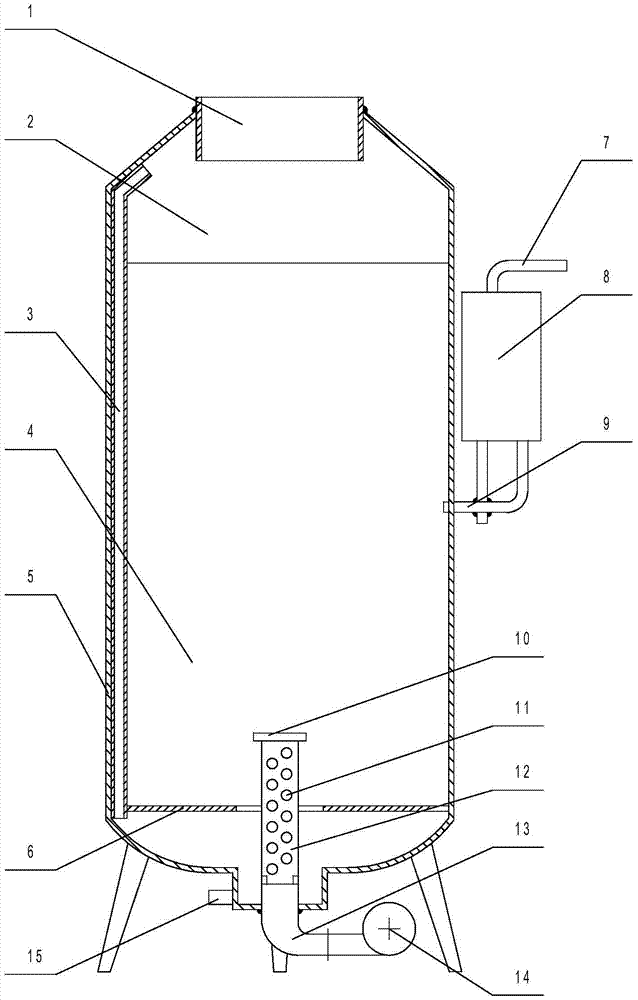

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] As can be seen from the structural representation of the gas stove of the present invention shown in the accompanying drawings, it includes a body of heater 5 with a cavity 2 inside, a blower 14 connected to the bottom of the body of heater 5, an exhaust pipe 9 communicating with the cavity 2 and a Filter cartridge 8 outside body of heater 5. The exhaust pipe 9 communicates with the filter cartridge 8, and the filter cartridge 8 is connected with an air supply pipe 7 for conveying gas to the outside. In the middle of the furnace bottom in the furnace body 5, there is a furnace core 12 communicating with the blower 14 air outlet. The furnace core 12 is a pipe with several through holes 11 on the surface, and a sealing plate 10 is fixed on the top of the furnace core 12. The bottom of the body of furnace 5 is provided with an in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap