Multiple-cavity high thrust energy-saving oil cylinder

A technology of large thrust and oil cylinder, applied in the direction of fluid pressure converter, fluid pressure actuating device, mechanical equipment, etc., can solve the problems of high manufacturing cost and large volume of hydraulic cylinder, reduce energy consumption, save installation space, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

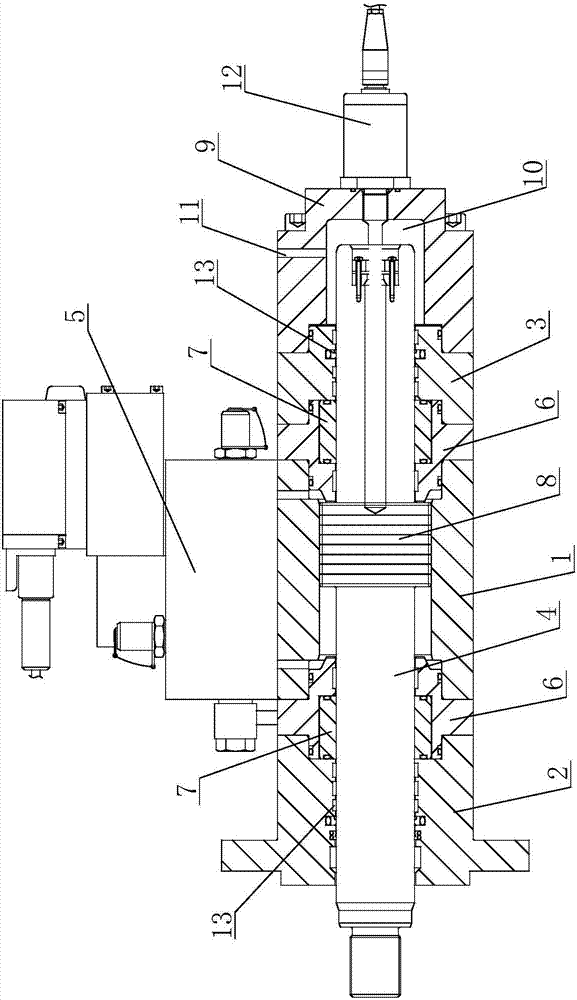

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0015] see figure 1 as shown, figure 1 It is a structural schematic diagram of the multi-cavity high-thrust energy-saving oil cylinder provided in Embodiment 1 of the present invention.

[0016] In this embodiment, a multi-cavity high-thrust energy-saving oil cylinder includes a cylinder body 1, a cylinder head 2, an end cover 3, a piston rod 4 and a control valve group 5, and the control valve group 5 is fixedly arranged on the cylinder body 1 , the cylinder head 2 and the end cover 3 are arranged at both ends of the cylinder body 1 respectively, and a spacer 6 is arranged between the cylinder head 2 and the end cover 3 and the cylinder body 1, and the spacer 6 A sealing ring 7 is arranged between 6 and the piston rod 4 . The middle part of the piston rod 7 is provided with a piston 8 that recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com