Cold plate module cooling system

A heat dissipation system and cold plate technology, applied in the computer field, can solve the problems of heat dissipation solutions that do not consider the large heat of internal modules, ignore the effective processing of liquid cooling plug-ins, and do not take them.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

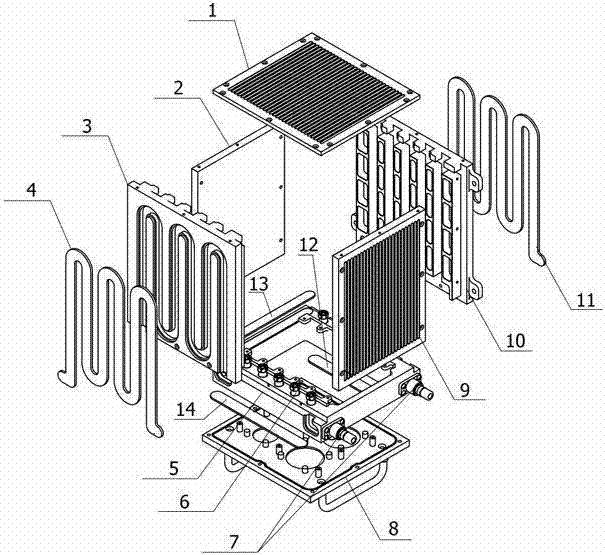

[0038] figure 1 The shown liquid-cooled chassis of the present invention is mainly composed of cover plate (1), left side plate (2), front wall plate (3), front wall plate-runner cover plate (4), base bracket (5), internal fluid Connector (6), external fluid connector (7), rear IO panel (8), right side panel (9), rear wall panel (10), rear wall panel-flow channel cover (11), base bracket- Runner cover plate 1 (12), base support-runner cover plate 2 (13), base support-runner cover plate 3 (14) form. Among them, the inner fluid connector (6) and the outer fluid connector (7) are Y121M-1Z03 and Y121MB-1Z05-A fluid connectors of Guizhou Aerospace Electric Co., Ltd. respectively.

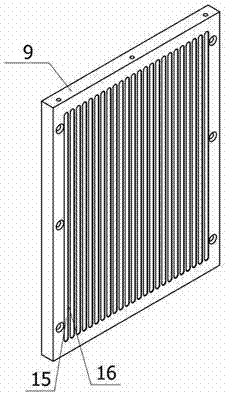

[0039] figure 2 As shown in the schematic diagram of the right side plate (9) of the present invention, the right side plate (9) adopts the cavity (15) formed by digging the plate, and the pattern of cooling fins (16) is formed between adjacent cavities (15), It is convenient to dissipate heat. Cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com