Split control rigging perpendicular storing device

A storage device and separate technology, applied in tool storage devices, manufacturing tools, etc., can solve the problems of easy safety accidents, large space occupied by rigging, easy loss of signs, etc., to achieve convenient storage and placement, and environmental adaptability Strong, avoid rain corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

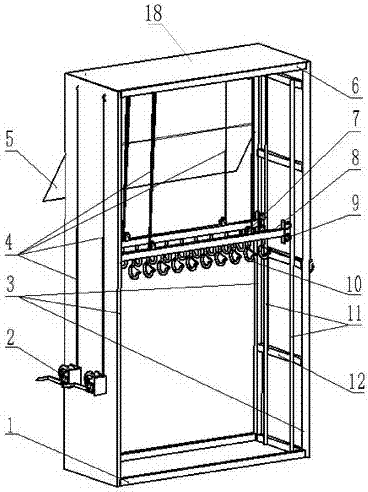

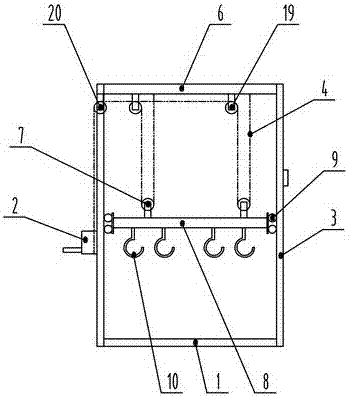

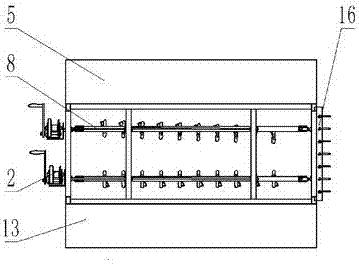

[0030] see Figure 1-5 , in the figure, the separate control rigging vertical storage device of the present invention includes bracket, top cover plate 18, two side sealing plates 14,15, front and rear rainproof covers 13,5, beam 8, hook 10, slideway 11, pulley block 9 and lifting mechanism, etc.

[0031] Wherein cover plate 18 is located at support top, and sealing plate 14,15 is located at support transverse both sides, and rainproof cover 13,5 is located at support top front and back both sides. Moreover, the top of the front and rear rainproof cover is respectively connected to the support by hinge rotation, and simultaneously, an air pressure spring 17 is respectively connected between the lower end of the front and rear rainproof cover and the support.

[0032] The support is a rigid upright rectangular frame structure composed of four vertical rectangular square tube columns 3, top beam 6 and base 1 fixedly connected by bolts. Two crossbeams 8 are arranged in parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com