Replaceable filter for in-situ leaching uranium mining drilling

A technology for in-situ leaching of uranium and filters, which is applied in the fields of mining fluids, earth-moving drilling, wellbore/well components, etc., to facilitate replacement and reduce failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

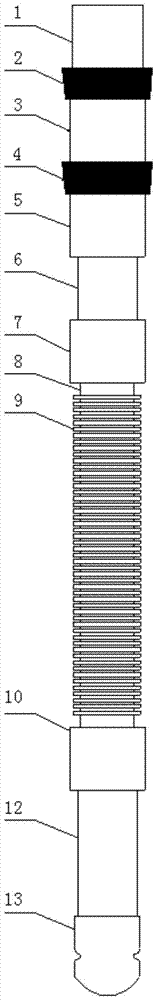

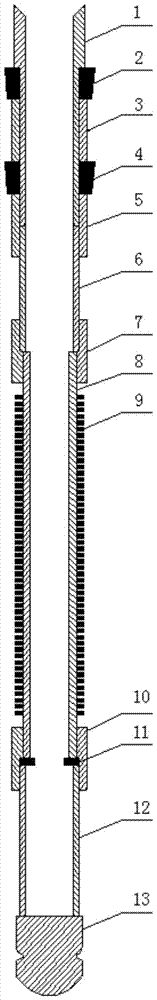

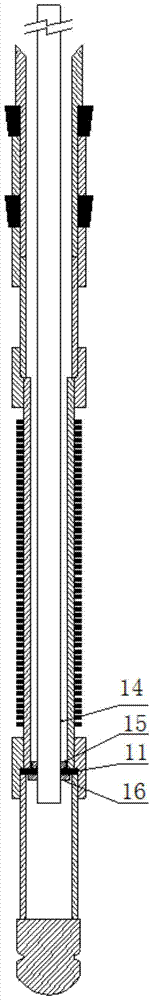

[0019] Such as figure 1 and figure 2 As shown, a replaceable filter for in-situ leaching uranium drilling, including a guide head 1, an upper sealing sand stop back rubber tube 2, an upper adjustment pipe collar 3, a lower sand sealing back stop rubber tube 4, and a lower adjustment tube Hoop 5, connecting pipe 6, upper reducing pipe hoop 7, filter pipe 8, filter ring frame 9, lower reducing pipe hoop 10, suspension snap ring 11, sand settling pipe 12 and anchoring head 13.

[0020] The pilot head 1 is ring-shaped as a whole, with a stepped cross-section. The outer diameter of the upper part is larger than the outer diameter of the lower part. With external thread. The upper sand-sealing anti-retreat rubber cylinder 2 has a circular shape as a whole, and its outer diameter gradually decreases from top to bottom. The upper sealing sand anti-retreat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com