High-efficiency dispensing equipment for shoemaking

A high-efficiency, glue-dispensing technology, applied in the direction of shoe-making machinery, footwear, applications, etc., can solve the problems of inconvenient use, low mechanical work efficiency, and high cost, and achieve high work efficiency, long service life, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

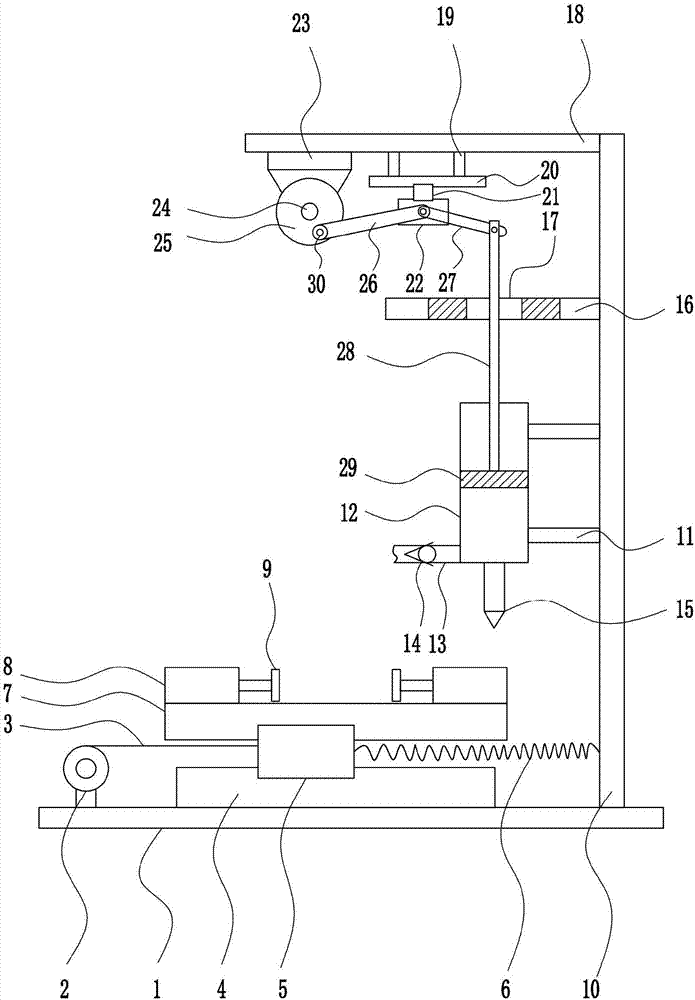

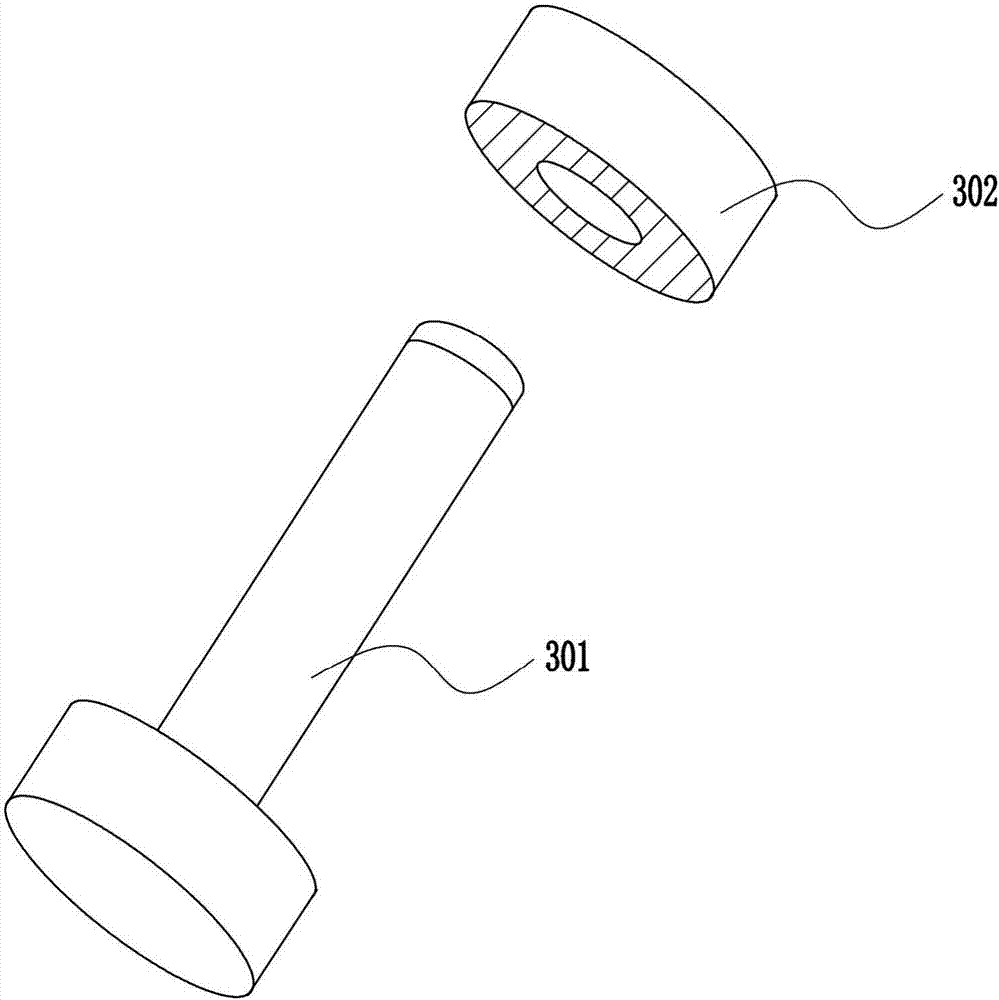

[0028] A kind of high-efficiency dispensing equipment for shoemaking, such as Figure 1-3As shown, it includes base plate 1, electric reel 2, steel wire rope 3, first slide rail 4, first slider 5, spring 6, first mounting plate 7, electric push rod 8, pressure block 9, right frame 10 , fixed rod 11, glue storage tank 12, feed pipe 13, one-way valve 14, dispensing head 15, guide plate 16, top plate 18, bracket 19, second slide rail 20, second slider 21, second installation Plate 22, mounting seat 23, rotating motor 24, turntable 25, first connecting rod 26, second connecting rod 27, third connecting rod 28 and piston 29, and the left side of the top of the bottom plate 1 is connected with electric winding by means of bolt connection Wheel 2, the electric reel 2 is provided with a wire rope 3, the middle of the top of the base plate 1 is connected with a first slide rail 4 by means of bolt connection, the first slide rail 4 is slidably connected with a first slide block 5, and t...

Embodiment 2

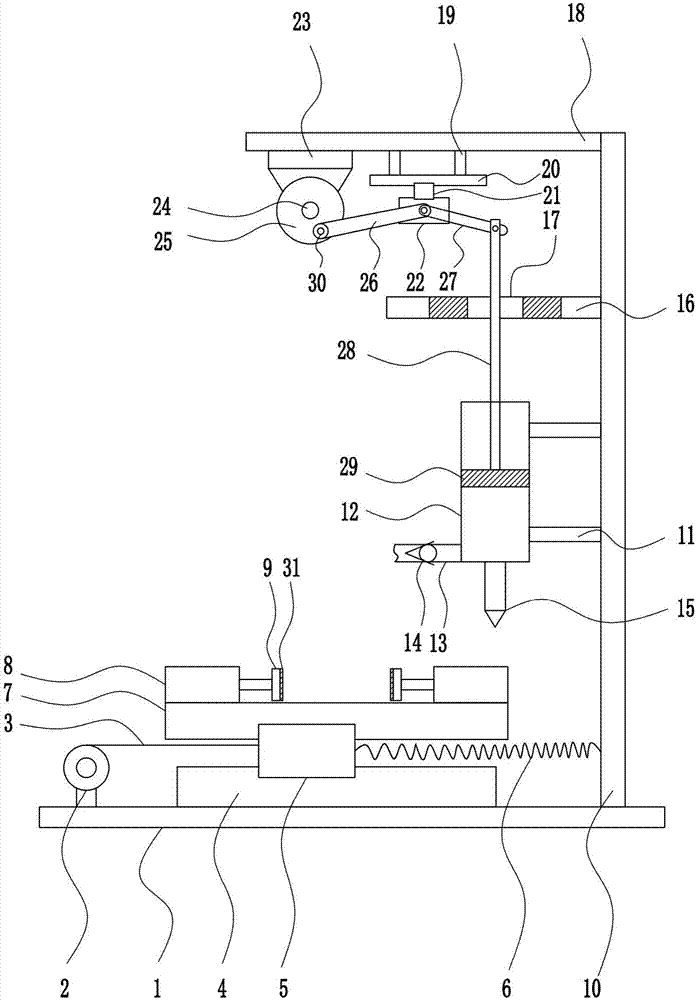

[0030] A kind of high-efficiency dispensing equipment for shoemaking, such as Figure 1-3 As shown, it includes base plate 1, electric reel 2, steel wire rope 3, first slide rail 4, first slider 5, spring 6, first mounting plate 7, electric push rod 8, pressure block 9, right frame 10 , fixed rod 11, glue storage tank 12, feed pipe 13, one-way valve 14, dispensing head 15, guide plate 16, top plate 18, bracket 19, second slide rail 20, second slider 21, second installation Plate 22, mounting seat 23, rotating motor 24, turntable 25, first connecting rod 26, second connecting rod 27, third connecting rod 28 and piston 29, and the left side of the top of the bottom plate 1 is connected with electric winding by means of bolt connection Wheel 2, the electric reel 2 is provided with a wire rope 3, the middle of the top of the base plate 1 is connected with a first slide rail 4 by means of bolt connection, the first slide rail 4 is slidably connected with a first slide block 5, and ...

Embodiment 3

[0033] A kind of high-efficiency dispensing equipment for shoemaking, such as Figure 1-3 As shown, it includes base plate 1, electric reel 2, steel wire rope 3, first slide rail 4, first slider 5, spring 6, first mounting plate 7, electric push rod 8, pressure block 9, right frame 10 , fixed rod 11, glue storage tank 12, feed pipe 13, one-way valve 14, dispensing head 15, guide plate 16, top plate 18, bracket 19, second slide rail 20, second slider 21, second installation Plate 22, mounting seat 23, rotating motor 24, turntable 25, first connecting rod 26, second connecting rod 27, third connecting rod 28 and piston 29, and the left side of the top of the bottom plate 1 is connected with electric winding by means of bolt connection Wheel 2, the electric reel 2 is provided with a wire rope 3, the middle of the top of the base plate 1 is connected with a first slide rail 4 by means of bolt connection, the first slide rail 4 is slidably connected with a first slide block 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com