Special sole placing device

A technology for placing boxes and pressing devices, which is applied in the direction of tool storage, packaging, transportation and packaging, etc. It can solve the problems of affecting work efficiency, inconvenient use, and affecting appearance, so as to improve work efficiency, be convenient to use, and not easy to fall out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

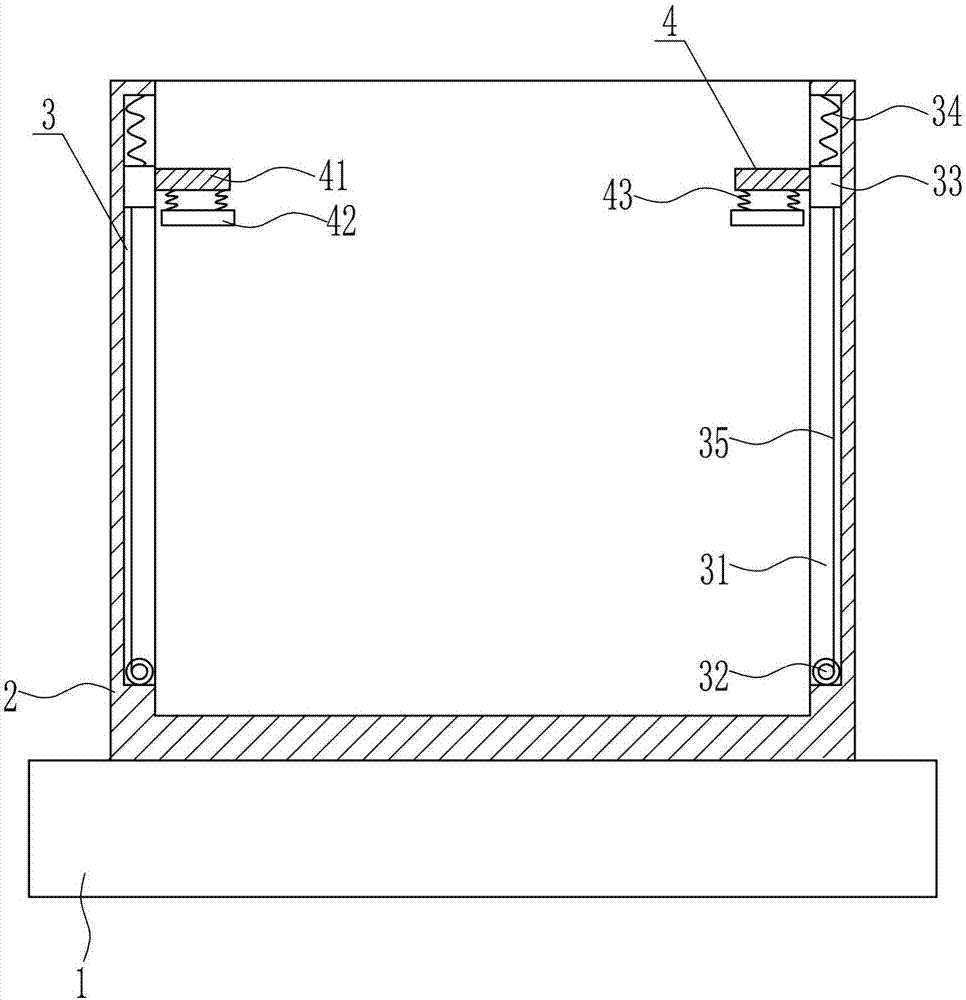

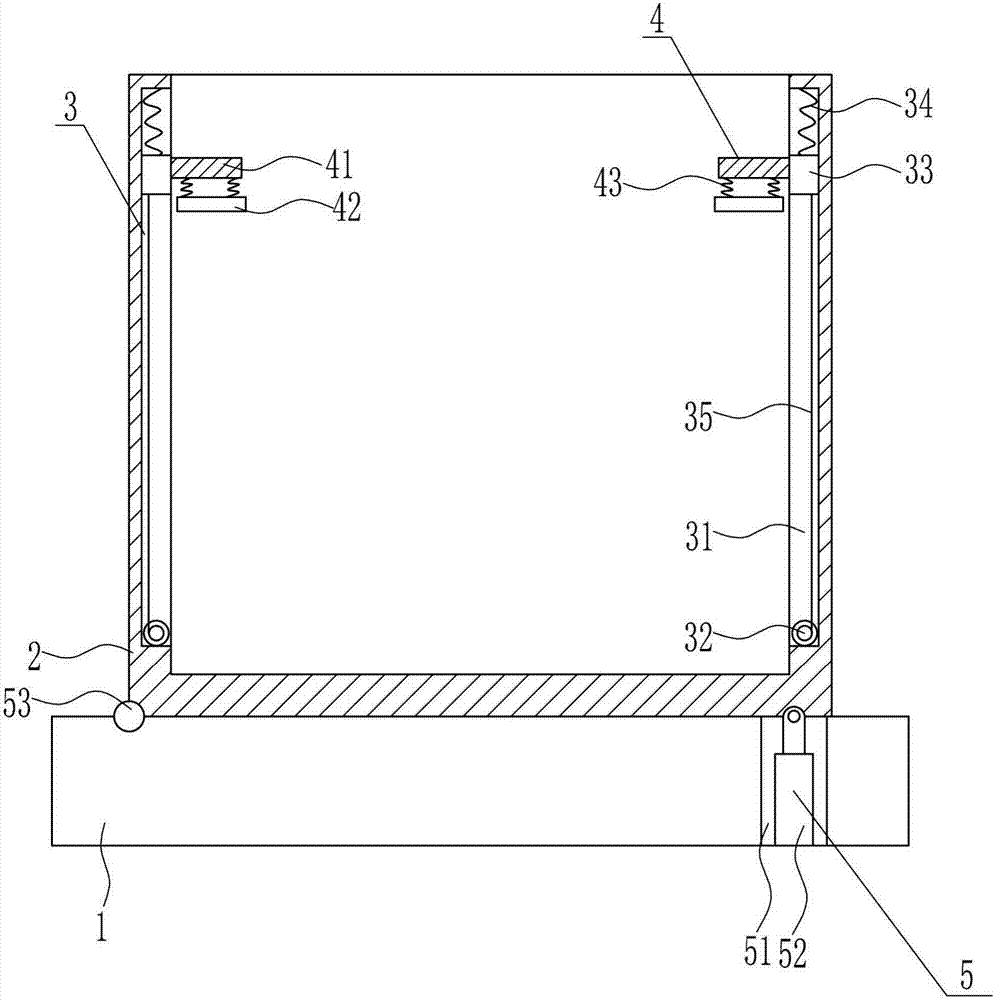

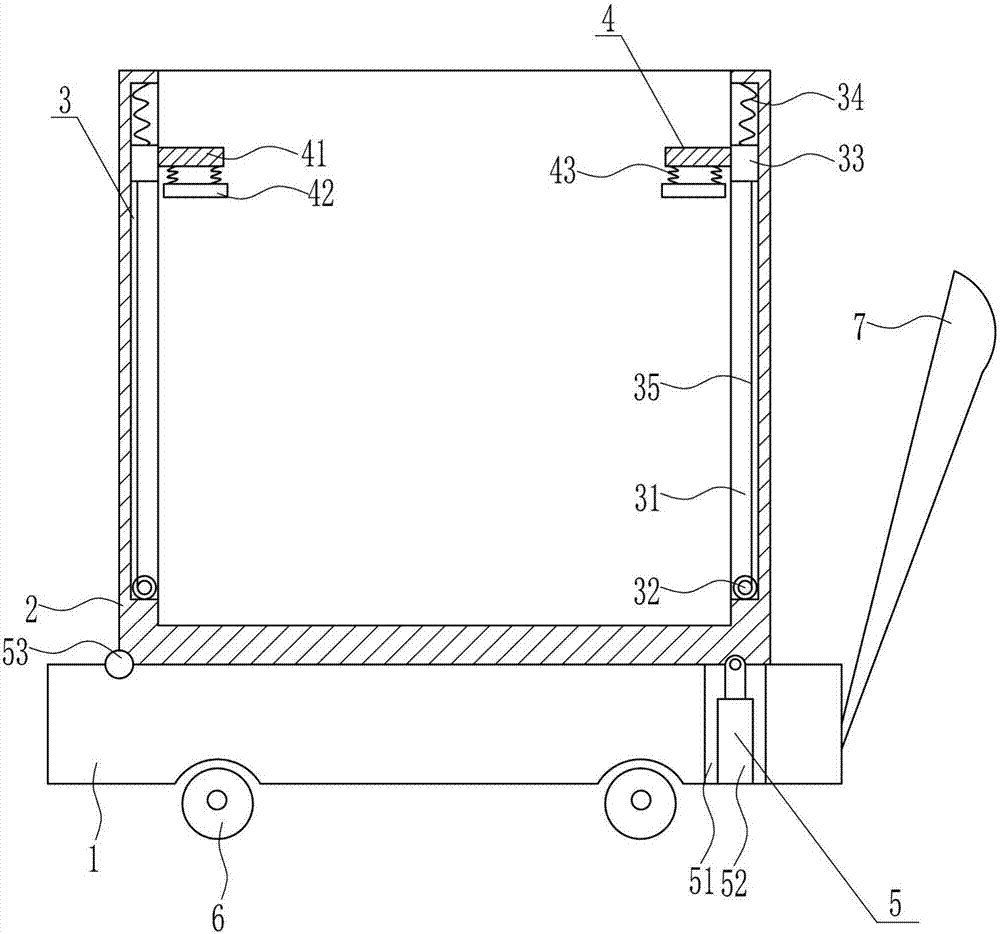

[0028] A special placement device for soles, such as Figure 1-4 As shown, it includes a base 1, a placement box 2, a height adjustment device 3 and a pressing device 4. The top of the base 1 is connected with a placement box 2 by means of bolt connection, and the inner side wall of the placement box 2 is provided with a height adjustment device 3. The height A pressing device 4 is provided on the adjusting part of the adjusting device 3 .

Embodiment 2

[0030] A special placement device for soles, such as Figure 1-4 As shown, it includes a base 1, a placement box 2, a height adjustment device 3 and a pressing device 4. The top of the base 1 is connected with a placement box 2 by means of bolt connection, and the inner side wall of the placement box 2 is provided with a height adjustment device 3. The height A pressing device 4 is provided on the adjusting part of the adjusting device 3 .

[0031] The height adjustment device 3 includes an electric reel 32, a slide block 33, a first spring 34 and a backguy 35, and there are chute 31 symmetrically arranged on the left and right side walls in the placement box 2, and the chute 31 is slidably provided with a slideway. Block 33, slide block 33 and chute 31 sliding fit, first spring 34 is connected between the top of slide block 33 and the inner top of chute 31, electric reel 32 is installed on the inner bottom of chute 31, electric reel 32 A stay wire 35 is wound on it, and the ...

Embodiment 3

[0033] A special placement device for soles, such as Figure 1-4 As shown, it includes a base 1, a placement box 2, a height adjustment device 3 and a pressing device 4. The top of the base 1 is connected with a placement box 2 by means of bolt connection, and the inner side wall of the placement box 2 is provided with a height adjustment device 3. The height A pressing device 4 is provided on the adjusting part of the adjusting device 3 .

[0034] The height adjustment device 3 includes an electric reel 32, a slide block 33, a first spring 34 and a backguy 35, and there are chute 31 symmetrically arranged on the left and right side walls in the placement box 2, and the chute 31 is slidably provided with a slideway. Block 33, slide block 33 and chute 31 sliding fit, first spring 34 is connected between the top of slide block 33 and the inner top of chute 31, electric reel 32 is installed on the inner bottom of chute 31, electric reel 32 A stay wire 35 is wound on it, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com