Yarn carrier capable of automatically replenishing and discharging yarns and three-dimensional knitting machine utilizing yarn carrier

A yarn carrier and knitting machine technology, applied in the field of yarn carriers and three-dimensional knitting machine equipment, can solve the problems of manually changing the fineness of the knitting yarn, changing the movement track of the yarn carrier, etc., and achieve the effect of improving weaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

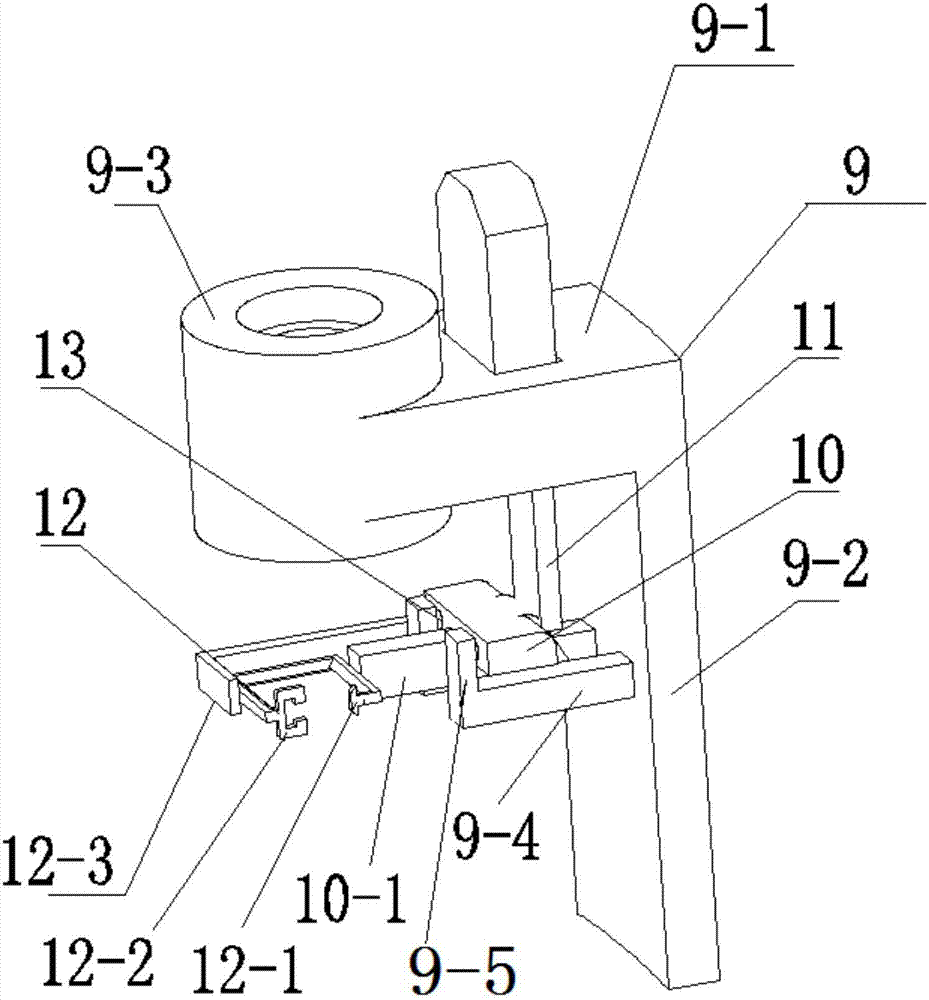

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

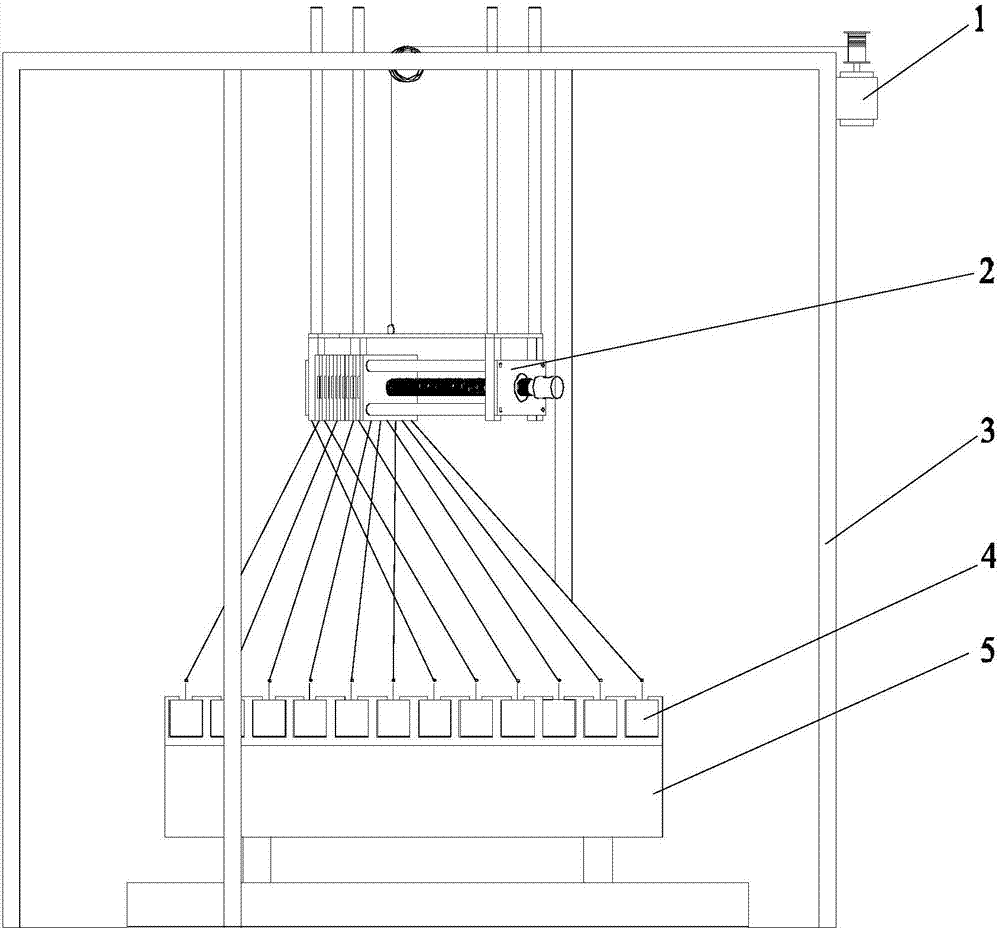

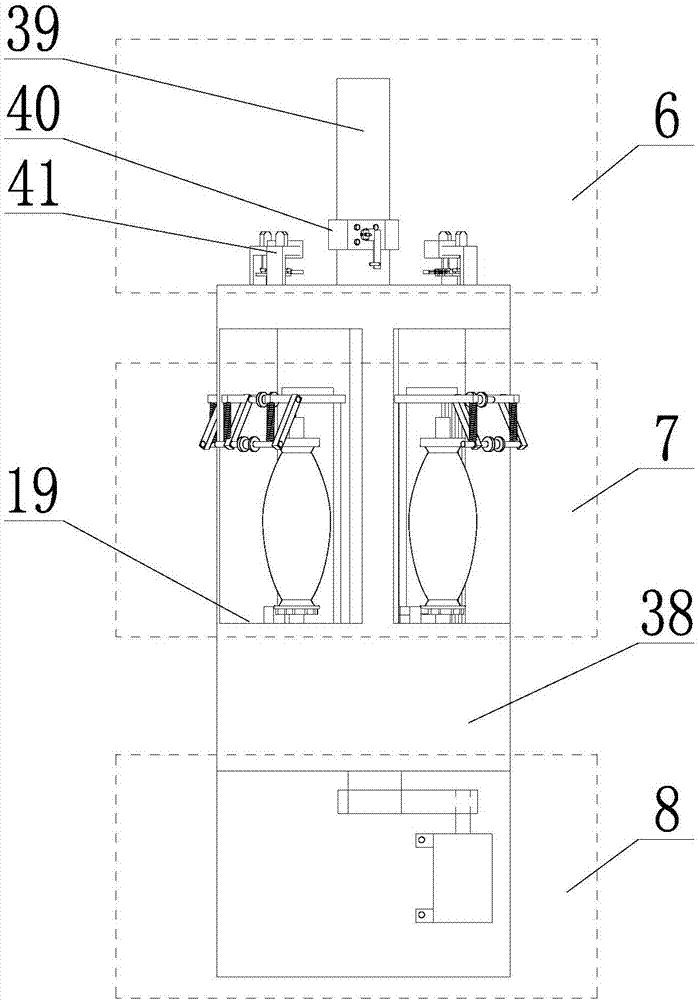

[0028] A three-dimensional knitting machine that can automatically increase and decrease yarns, such as figure 1 As shown, it includes a braiding frame 3 and a lead-off motor 1 arranged on the braiding frame 3, a preforming chuck 2, a chassis 5 and a plurality of yarn carriers 4, the chassis 5 is located at the bottom of the braiding frame 3, and a plurality of The yarn carriers 4 are arranged and installed on the chassis 5, the preforming chuck 2 is located directly above the yarn carriers 4, fixed on the knitting frame 3 through the connecting rod, and the yarn drawn from the yarn carriers 4 passes through the preforming clamps The head 2 is controlled, and the weaving frame 3 is equipped with a lead-away motor 1, which is used to control the preforming chuck 2, and the preform that is formed as weaves is gradually led away from the forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com