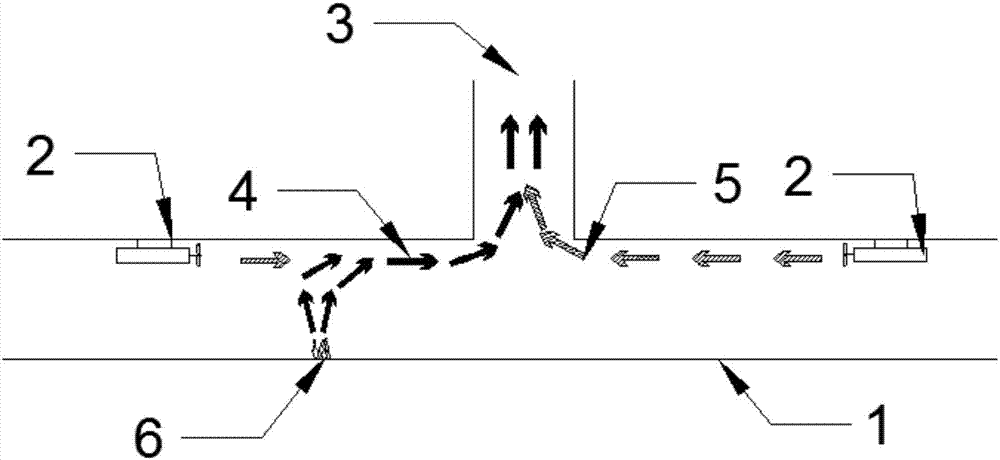

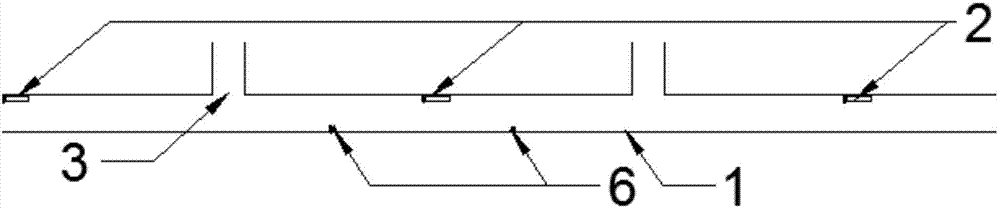

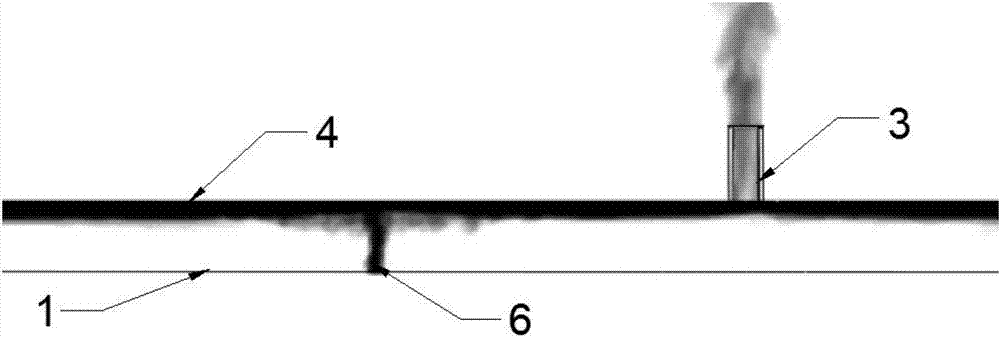

Tunnel ventilation and smoke exhaust system and method

A tunnel ventilation and smoke exhaust system technology, applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., can solve problems such as direct disturbance of the interface between smoke and air, cold air in the lower part of the shaft, and reduced smoke exhaust efficiency , to achieve the effect of improving natural smoke exhaust effect, low economic investment and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that the technical terms used in the present invention are only used to describe specific embodiments, and are not intended to limit the present invention. And, unless specifically defined in other meanings in the present invention, the technical terms used in the present invention should be interpreted as meanings that can be generally understood by those with basic knowledge in the technical field to which the present invention belongs.

[0031] In addition, singular expressions used in the present invention include plural expressions unless different meanings are clearly indicated in the context of documents. In the present invention, terms such as "consisting" or "comprising" cannot be interpreted as necessarily including the described constituent elements or steps, and some of the constituent elements or steps may not be included, or additional constituents may also be included. elements or steps.

[0032] Here, it needs to be explained that whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com