Repeated positioning precision detection method of white vehicle body main splicing clamp switching system

A repeat positioning accuracy and switching system technology, which is applied in the field of repeated positioning accuracy detection of the body-in-white main assembly fixture switching system, can solve the problems of difficulty in ensuring positioning accuracy, time-consuming, and inability to realize real-time detection of body-in-white welding, and achieve satisfactory accuracy required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

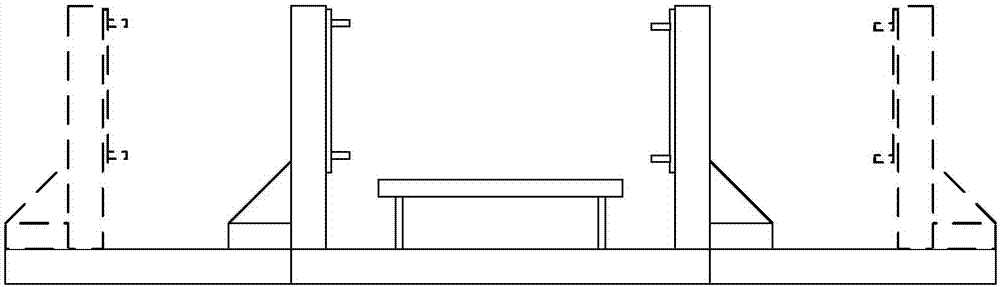

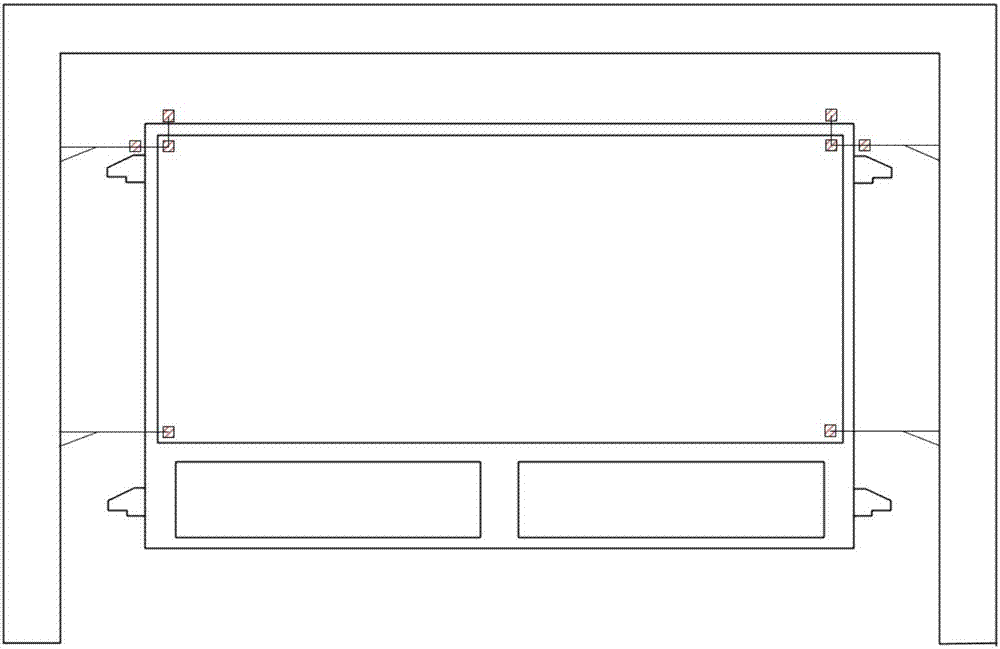

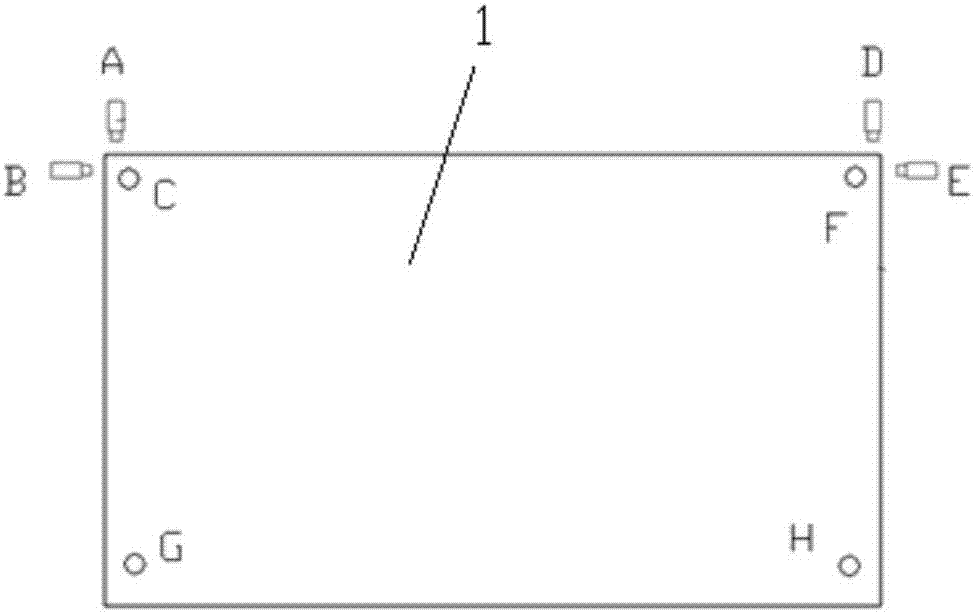

[0021] figure 1 It is a structural schematic diagram of the present invention. As shown in the figure, the repeated positioning accuracy detection method of the body-in-white main assembly fixture switching system of this embodiment includes the following steps: a. Select a plurality of measured points on the main assembly fixture substrate, and fixedly set a plurality of points corresponding to the A plurality of probes with one-to-one correspondence of the measuring points; b. measure the distance value between each of the measured points and the corresponding measuring heads; c. repeat step b and obtain multiple sets of the measured points and The distance value between the corresponding measuring heads; d. Calculate the absolute position accuracy X of each said measured point and its ideal position ij ;X ij =x ij -x i , where X ij is the absolute position accuracy of the j-th measurement of the i-th measured point, x ij is the distance value measured for the jth time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com