Twisting device for electrical conductors

An electrical conductor, twisting technology, applied in conductor/cable supply devices, cable/conductor manufacturing, circuits, etc., can solve problems such as high rejection, response delay, difficult error, etc., to achieve simple and easy adjustment, easy adjustment, and quality improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

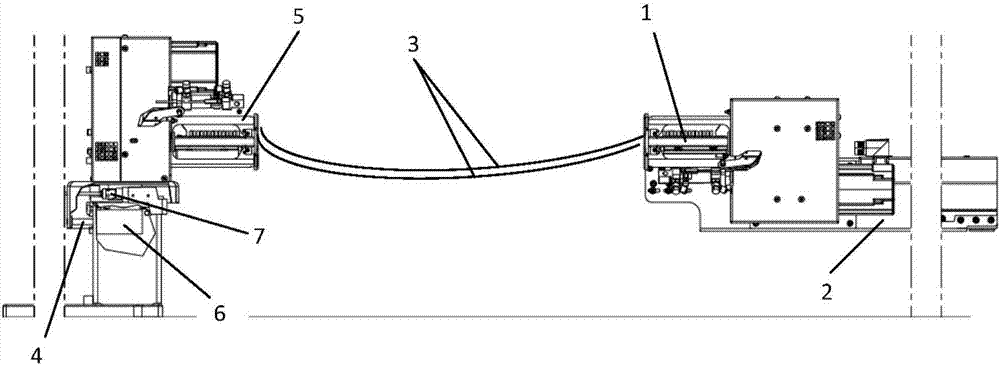

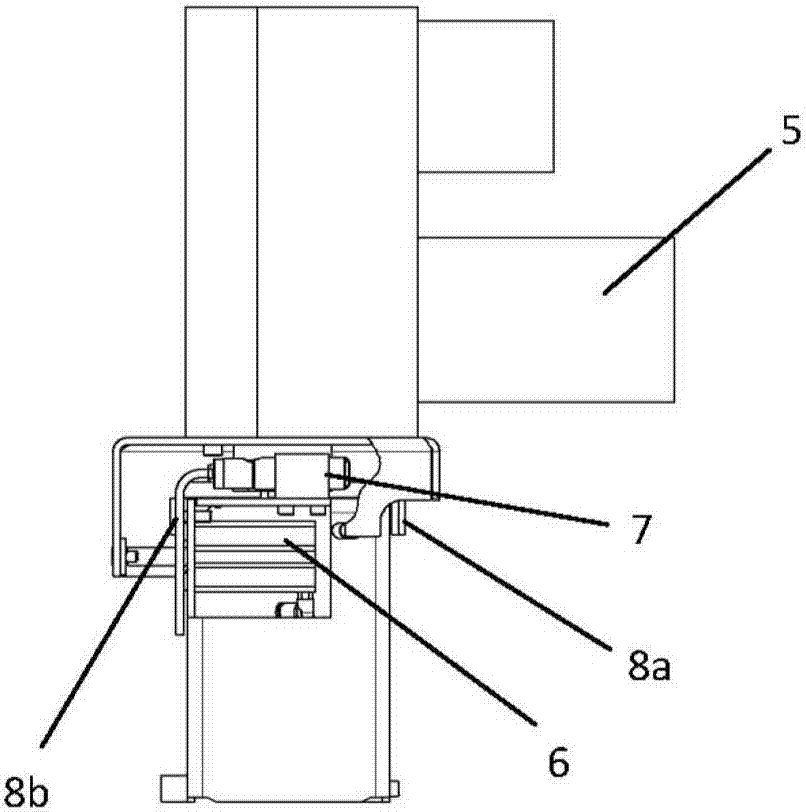

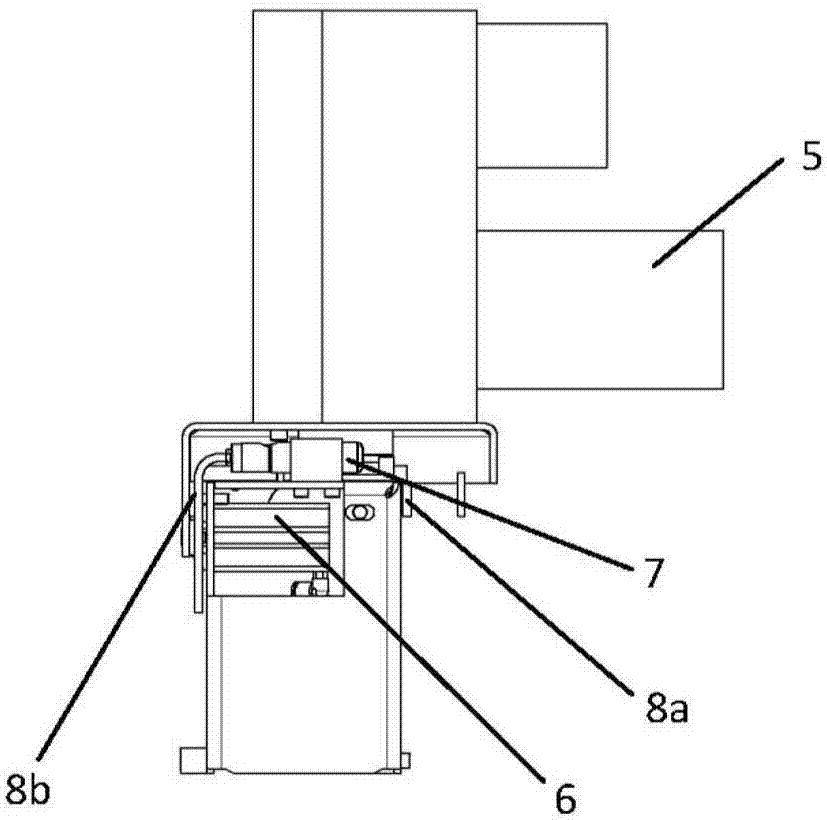

[0044] figure 1 The illustrated twisting device, which compensates for the shortening of the target length during the twisting process, has a twisting head 1 . The pair of conductors 3 to be twisted is held in position on the side opposite to the twisting head 1 by the second twisting head 5, wherein the two twisting heads 1, 5 can be rotated in opposite directions about a common axis of rotation . It is also possible to provide a non-rotating clamping device instead of the second twisting head 5 . As a variant, it is also possible to provide a non-rotating clamping device instead of the first twisting head 1 , in which case the second twisting head 5 is rotated. In principle, twisting of three or more conductors is also conceivable if the twisting heads 1 , 5 and the clamping device, in particular its clamping mechanism, are designed accordingly.

[0045] After the conductor pair 3 has been transferred to the twisting head 1 , 5 , the conductors are first arranged paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com