Automatic feeding device for mixing agent for smelting of rubber conveyer belt

An automatic adding and conveyor belt technology, applied in the field of rubber refining equipment, can solve the problems of inability to guarantee the mixing temperature and adding speed, and achieve the effect of reducing the dependence on manual labor, reducing labor costs, and improving mixing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

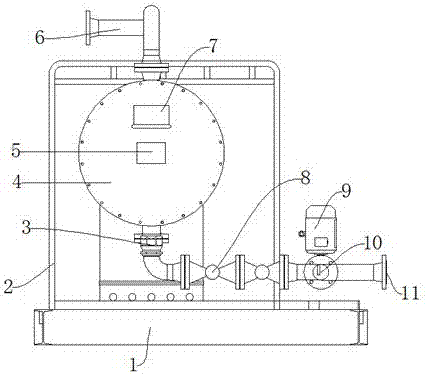

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] like figure 1 As shown, a compounding agent automatic adding device for rubber conveyor belt mixing includes a base 1, a compounding agent storage tank 4 and a motor 9, a protective shell 2 is installed above the base 1, and an electric heat insulator is installed inside the compounding agent storage tank 4 5. A temperature indicator 7 is installed on the shell of the matching agent storage tank 4, and a matching agent injection pipe 6 is installed above the matching agent storage tank 4. The matching agent storage tank 4 is connected with the filter material 8 through the automatic discharge device 3, and the motor 9 is connected with the material filter 8 through a pressurizing pump 10, and an adding head 11 is installed at the end of the pressurizing pump 10.

[0017] In the above structure, the compounding agent is injected into the compounding agent storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com