A counterweight transportation rail and a counterweight transportation method

A track and counterweight technology, applied in transportation and packaging, lifting equipment in mines, elevators, etc., to achieve the effect of improving safety and operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below using the drawings. The shapes, numbers, materials, and the like described below are examples for explanation, and can be appropriately changed according to the specifications of the elevator to which the transport rail is applied. Hereinafter, the same reference numerals will be assigned to the same elements in all the drawings and will be described. In addition, in the description herein, the reference numerals described above are used as necessary.

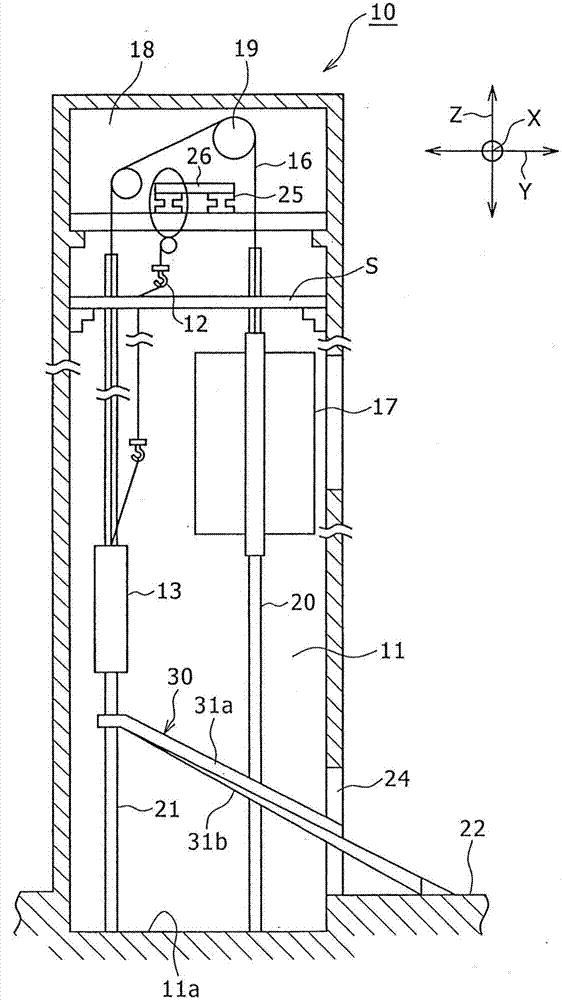

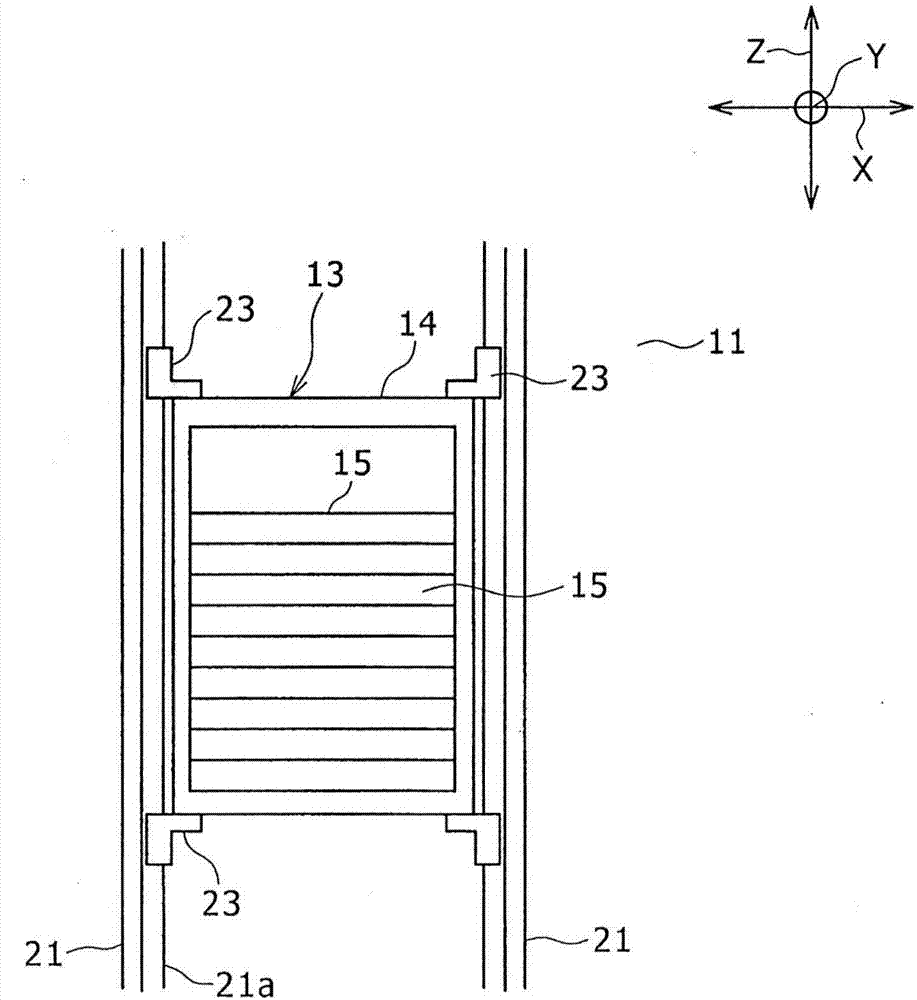

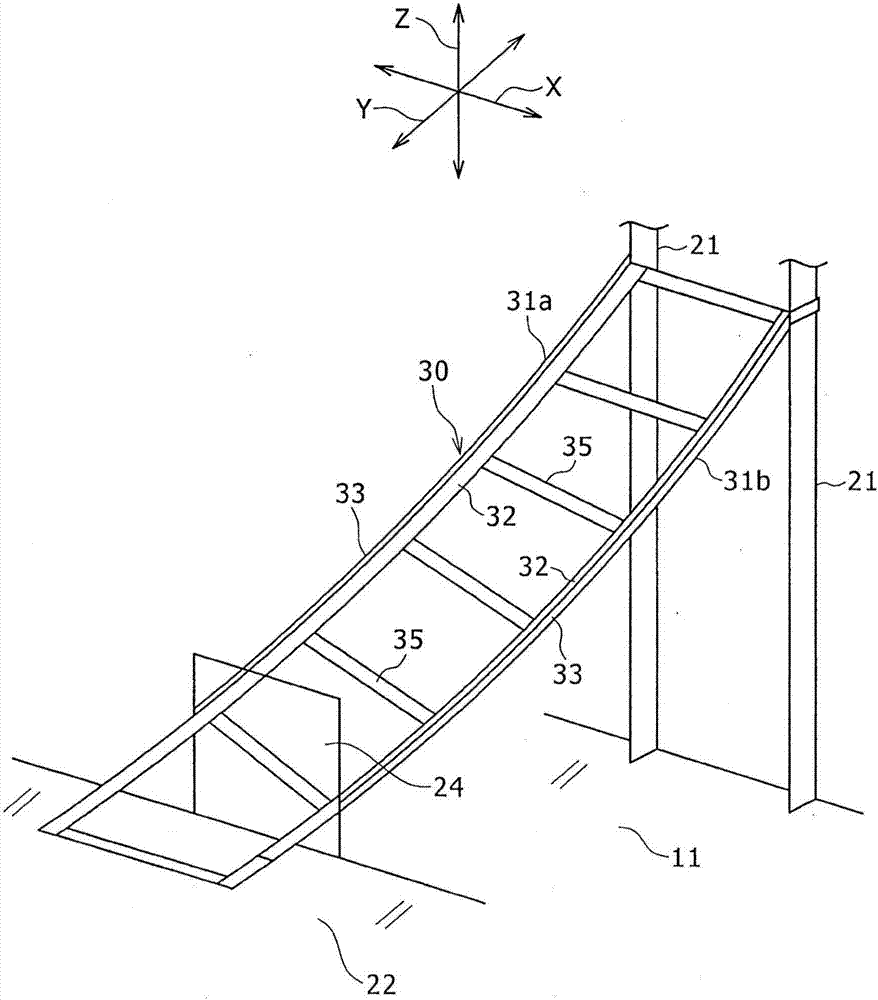

[0027] figure 1 It is a cross-sectional view showing a state in which the conveying rail 30 is installed in the elevator 10 to which the counterweight conveying rail of the embodiment is applied, and the lifting device 12 and the counterweight 13 are connected.

[0028] The elevator 10 has a counterweight 13 connected to a car 17 via a main rope 16 in a hoistway 11 . The main rope 16 is driven by a traction machine 19 arranged in a machine room 18 at the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com