Potato and soil separation regulating device for potato lifter

A technology of adjusting device and harvester, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of affecting separation efficiency and harvest quality, damage to potatoes, limited amplitude and frequency adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

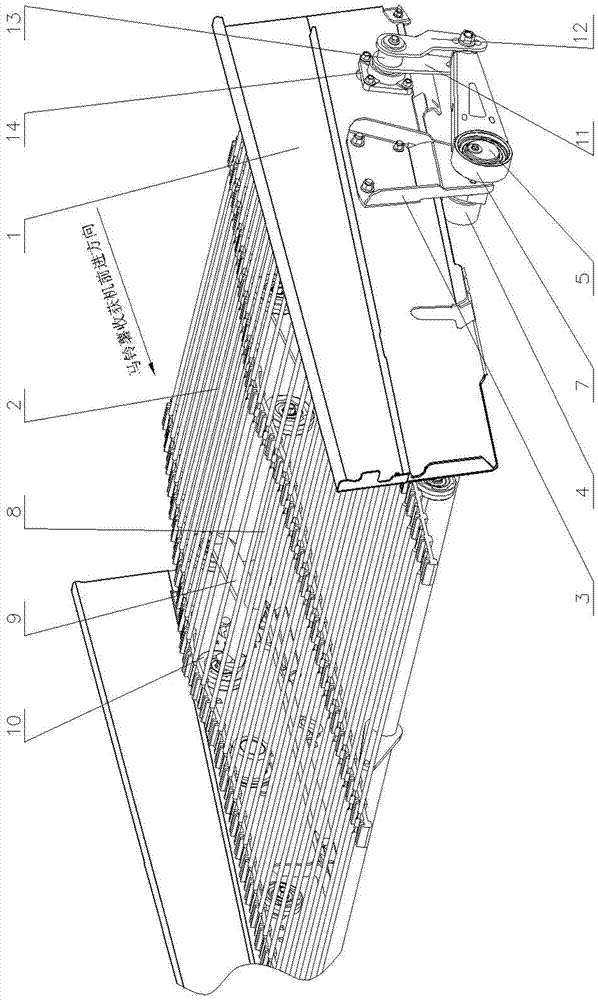

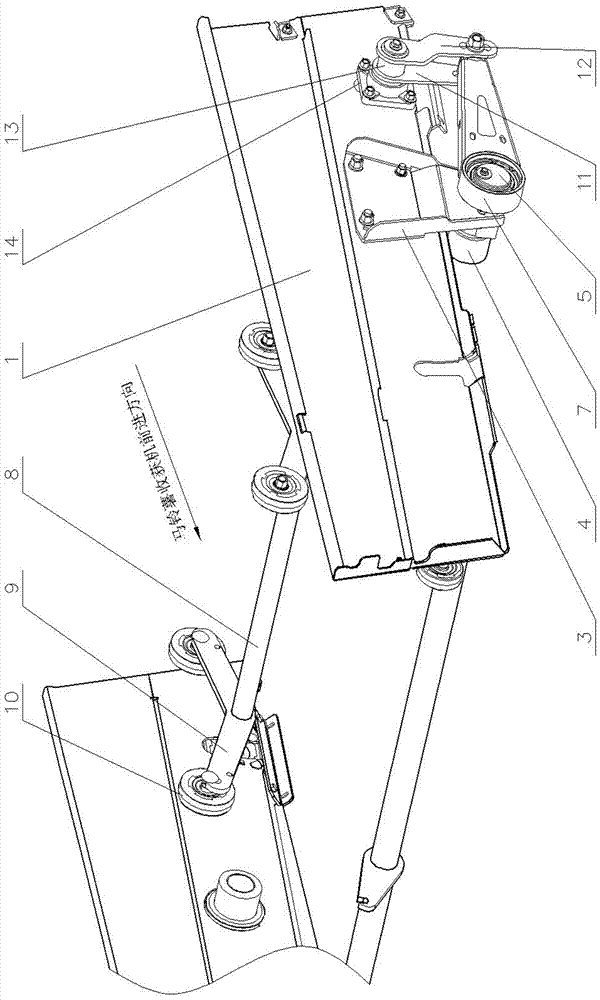

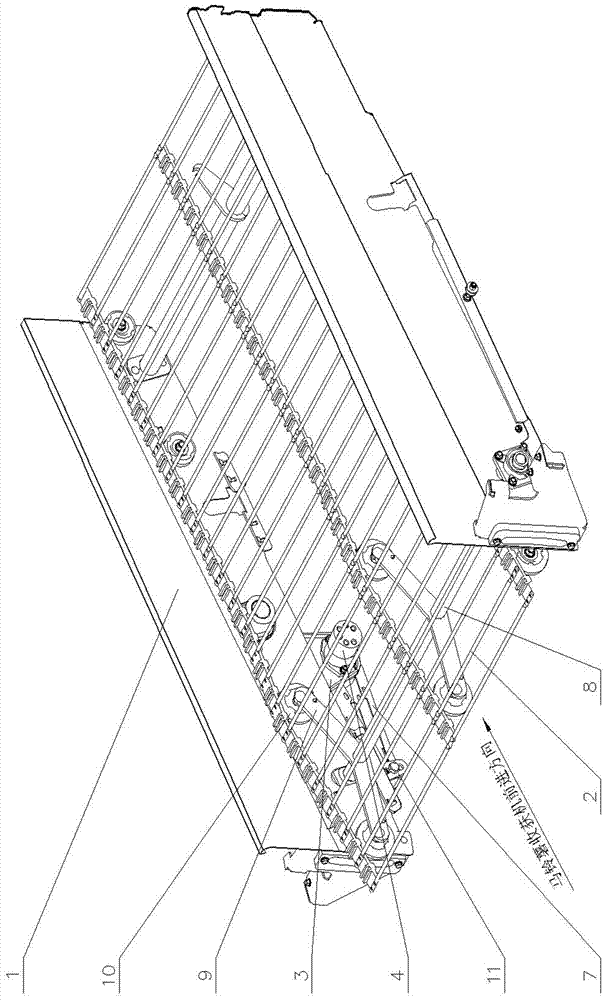

[0014] 1. Rack 2, separation screen 3, mounting plate 4, hydraulic motor 5, eccentric wheel 6, bearing 7, connecting rod 8, shaft 9, rubber wheel frame 10, rubber wheel 11, straight arm 12, curved arm 13, sleeve Tube 14, bearing seat 15, bearing pin.

[0015] exist Figure 1~5 In the shown embodiment: the mounting plate 3 is fixed on the side plate on one side of the frame 1, and the downward extending end is provided with a round hole whose axis is perpendicular to the advance direction of the harvester, and the output of the hydraulic motor 4 in the vibration adjustment device The shaft is inserted into the round hole below the mounting plate 3 from the side of the mounting plate 3 close to the frame 1, and installed on the side of the mounting plate 3 close to the frame 1. The output shaft of the hydraulic motor 4 passes through the round hole of the mounting plate 3 The protruding end is equipped with an eccentric wheel 5, and the two ends of the outer circle of the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com