Punch pin drive device for press machine

A driving device and press technology, applied in the field of presses, can solve problems such as wasting electric energy, smashing molds, increasing machine height, etc., and achieves the effect of simple and reasonable structural design, simple structure, and lower product height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

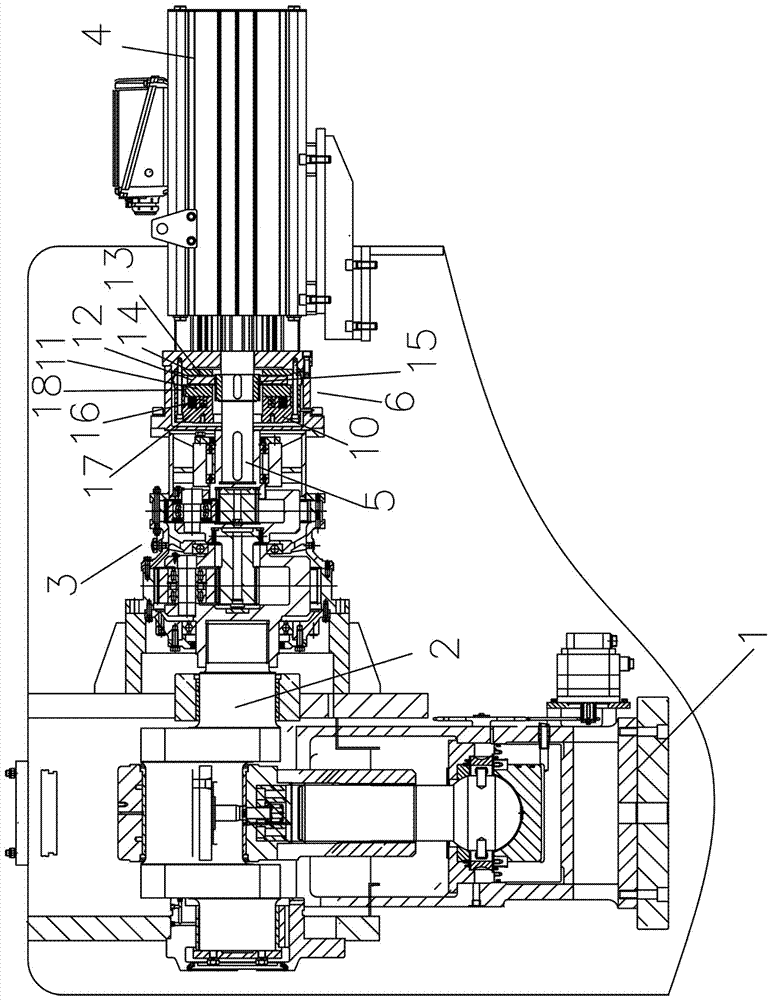

[0011] A punch driving device for a press, including a punch 1, a crank 2, a planetary reducer 3, and a servo motor 4, the crank 2 is connected to the planetary reducer 3, and the planetary reducer 3 and the servo motor 4 have an output shaft 5 Connected, the output shaft 5 of the servo motor is provided with a brake 6 .

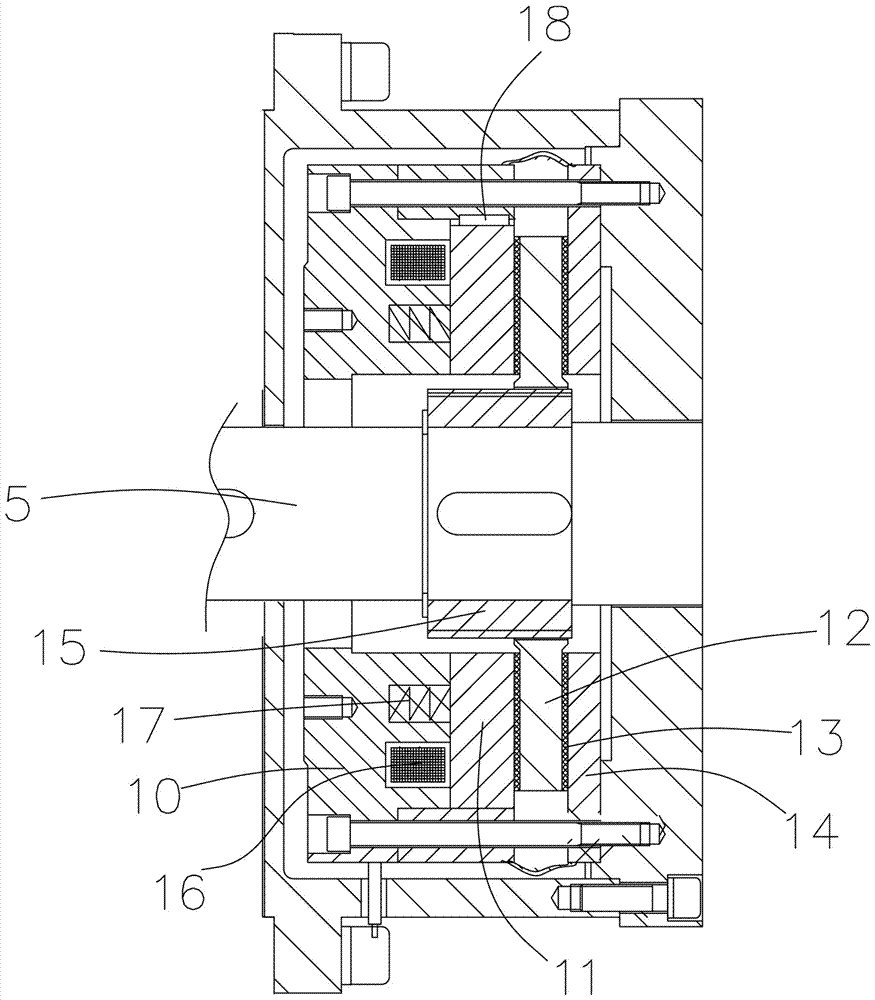

[0012] The brake 6 includes a stator 10, an armature 11, a rotor 12, a friction plate 13 and a flange 14. The rotor 12 is connected to the output shaft 5 of the servo motor through a splined bushing 15 and moves in unison. The stator 10 is provided with a coil 16 and a spring 17. The spring 17 is coaxial with the output shaft 5 of the servo motor. One end of the spring 17 is placed inside the stator 10, and the other end is placed on the armature 11. The outer ring of the armature 11 is provided with a flat key 18 to limit the armature to only move al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com