Concentric winding type automatic conversion device for winding mold

A technology of automatic conversion and winding mode, which is applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc. line etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

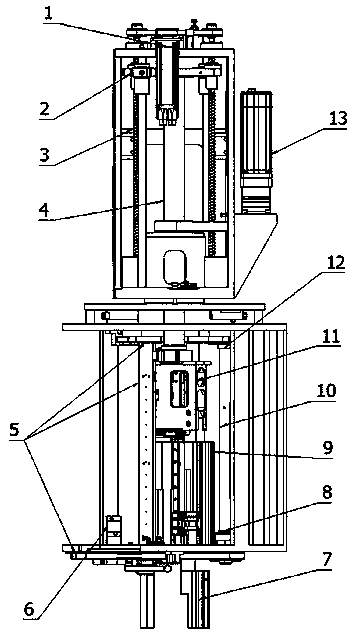

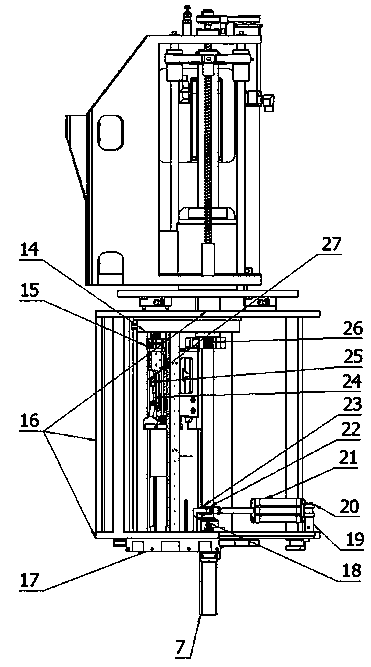

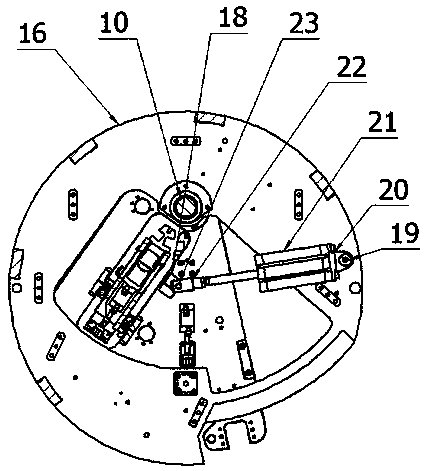

[0012] Specific implementation method: reference figure 1 , Figure 5 . The mold sinking motor 1 drives the screw 3 to rotate so that the sinking mold slider 2 fixedly connected with the screw nut drives the sinking mold shaft 4 to move up and down, and the lower end of the sinking mold shaft 4 is equipped with a latch lock block 26; the right winding mold 7 is fixedly connected At the lower end of the transposition support 5, the left winding die 9 distributed at an angle with the right winding die 7 is fixedly connected below the lifting support 11; the two sides of the lifting support 11 are equipped with guide rail sliders 24 and guide rail clamps 25, and the guide rail The slide block 24 and the guide rail clamp 25 cooperate with the guide rail 27 mounted on the transposition bracket 5, and the switch of the guide rail clamp 25 can produce two states of fixing and sliding with the guide rail 27; , when the left winding die 9 is located at the center of the winding brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com