Unwinding machine, insulated wire production device and unwinding method

A pay-off machine and wire technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems affecting the production efficiency of insulated wires, wire accumulation and winding, and inconvenient production recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

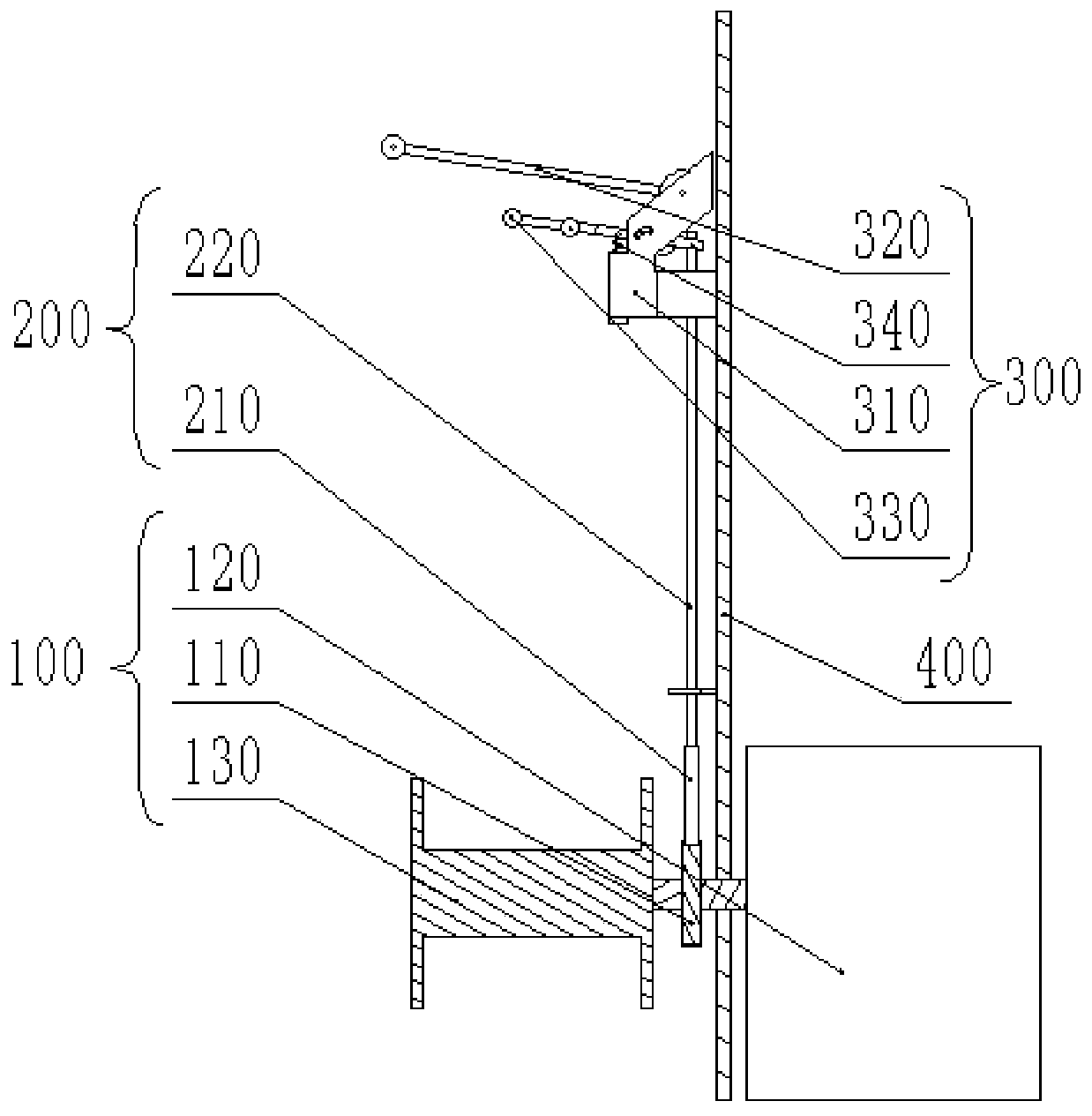

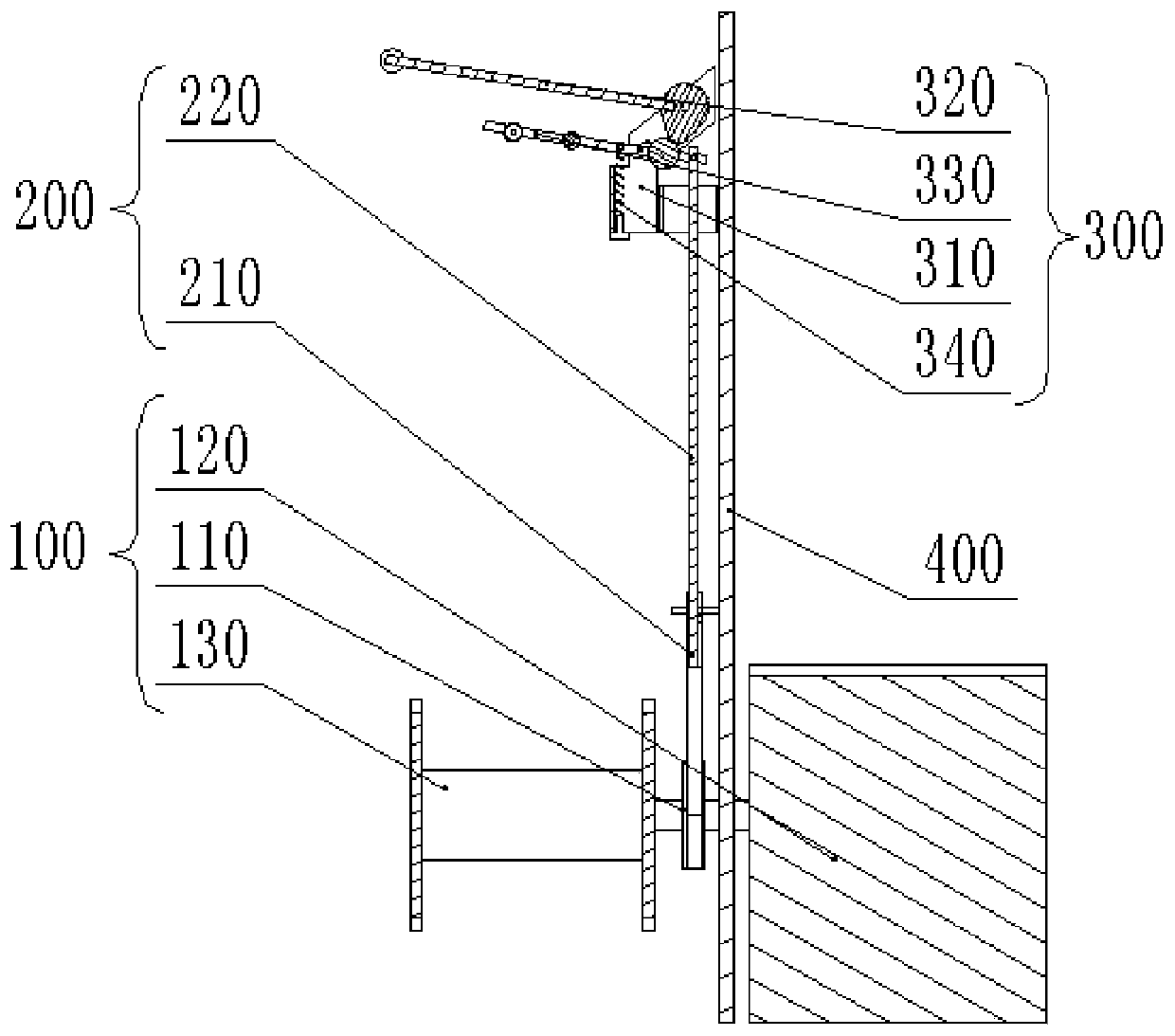

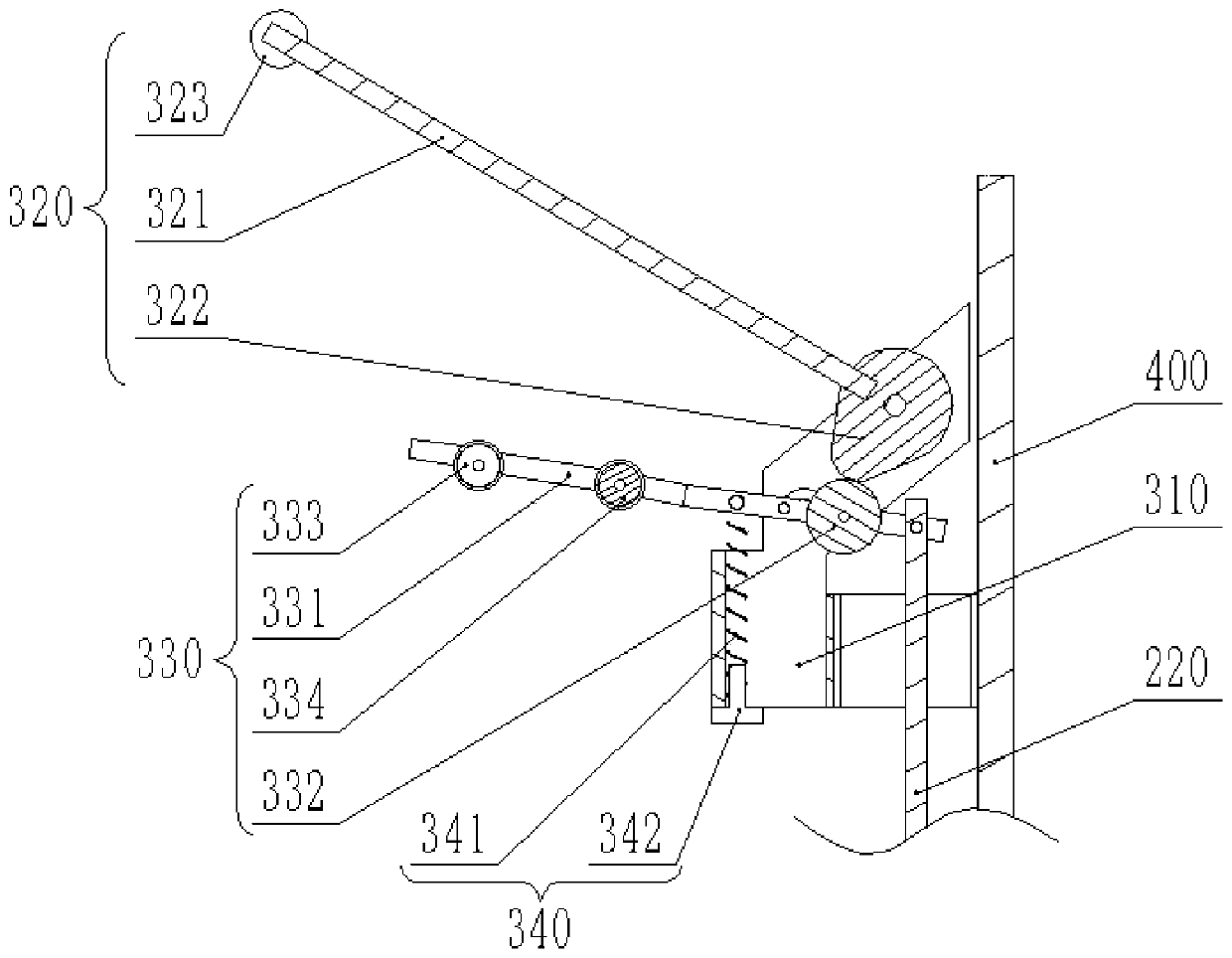

[0042] Such as figure 1 As shown, the pay-off machine provided by the embodiment of the present invention includes: a pay-off mechanism 100, a brake mechanism 200, and a transmission mechanism 300; the transmission mechanism 300 is connected to the brake mechanism 200; to the transmission mechanism 300 and output through the transmission mechanism 300; the transmission mechanism 300 is configured to drive the braking mechanism 200 in an off-line state to brake the wire-releasing mechanism 100.

[0043] Specifically, the wire output by the pay-off mechanism 100 is wound around the transmission mechanism 300. When the wire falls off on the transmission mechanism 300, or when the wire breaks, the transmission mechanism 300 drives the braking mechanism 200, thereby passing through the braking mechanism 200. Brake the pay-off mechanism 100 to stop the pay-off mechanism 100 from paying out.

[0044] Such as figure 1 with figure 2 As shown, in the embodiment of the present invent...

Embodiment 2

[0059] The insulated wire production device provided in the embodiment of the present invention is equipped with the wire pay-off machine provided in the second embodiment. Among them, the insulated wire production device has the same technical effect as the pay-off machine, so it will not be repeated here.

Embodiment 3

[0061] Such as figure 1 with figure 2 As shown, the wire releasing method provided by the embodiment of the present invention includes the following steps: the wire is output from the wire feeding mechanism 100 through the conveying mechanism 300; when the wire is wound around the conveying mechanism 300, the conveying mechanism 300 drives the braking mechanism 200 releases the brake on the pay-off mechanism 100; when the wire is disengaged from the guide mechanism 300, the guide mechanism 300 drives the brake mechanism 200 to brake the pay-off mechanism 100. Using the pay-off machine provided in Embodiment 1, when the wire breaks or breaks away from the guide mechanism 300, the brake mechanism 200 is driven by the guide mechanism 300 to brake the pay-off mechanism 100, thereby avoiding the accumulation and entanglement of the wire. It is convenient for maintenance and quick recovery of production, which can shorten the troubleshooting time of the pay-off machine and improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com