Automatic moxa stick rolling machine for cleaning moxa sticks and use method of automatic moxa stick rolling machine

A technology for clearing moxa sticks and moxa sticks, which is applied in the direction of winding strips, making medicines into special physical or ingestible devices, heating/cooling reflection point instruments, etc., which can solve the problem of uneven diameter and size of moxa sticks, Problems such as roughness and reduced equipment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

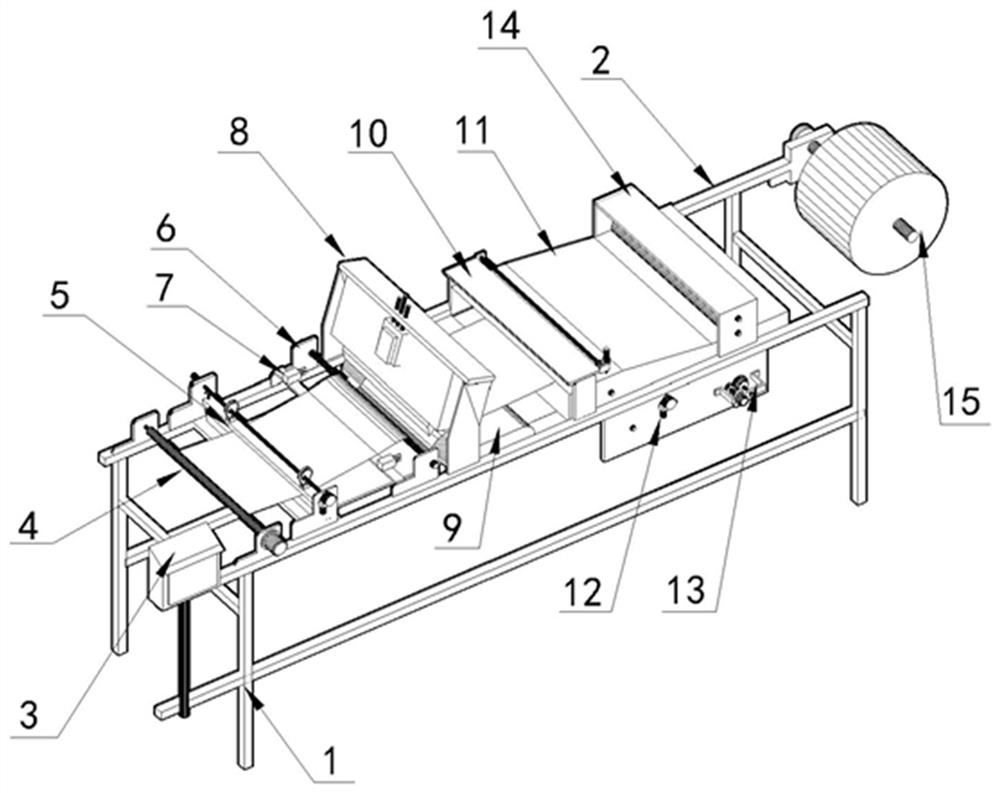

[0046] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Concerning the specific mechanical structure of the present invention, refer to below Figure 1 to Figure 6 The detailed description of the structure will clearly show that the structural content mentioned in the following embodiments are all based on the accompanying drawings.

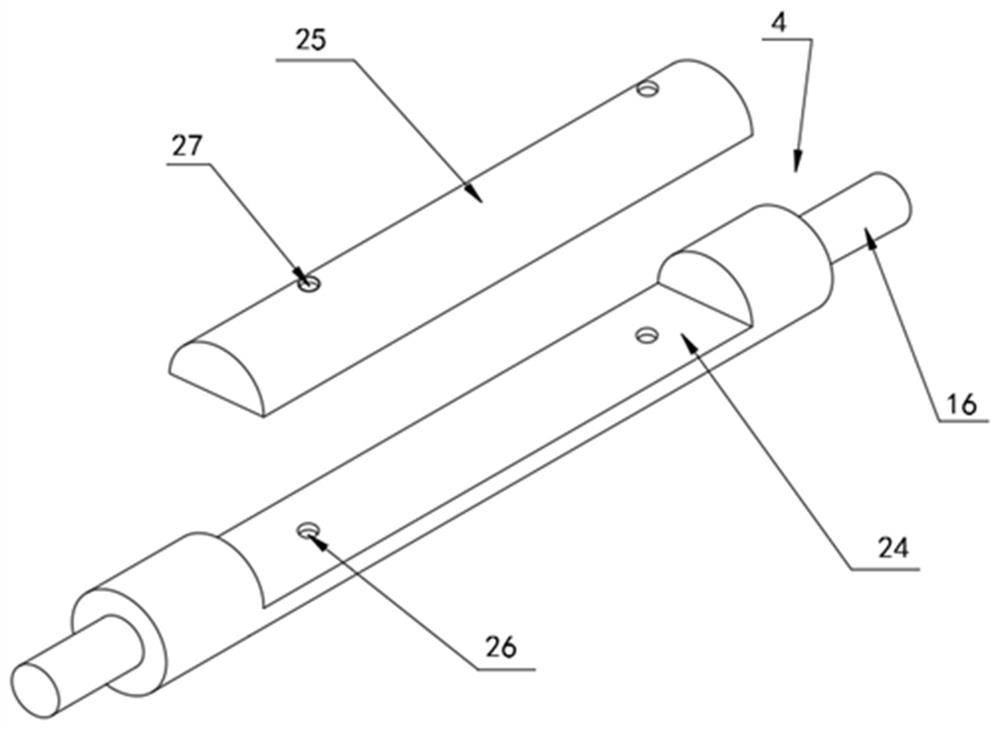

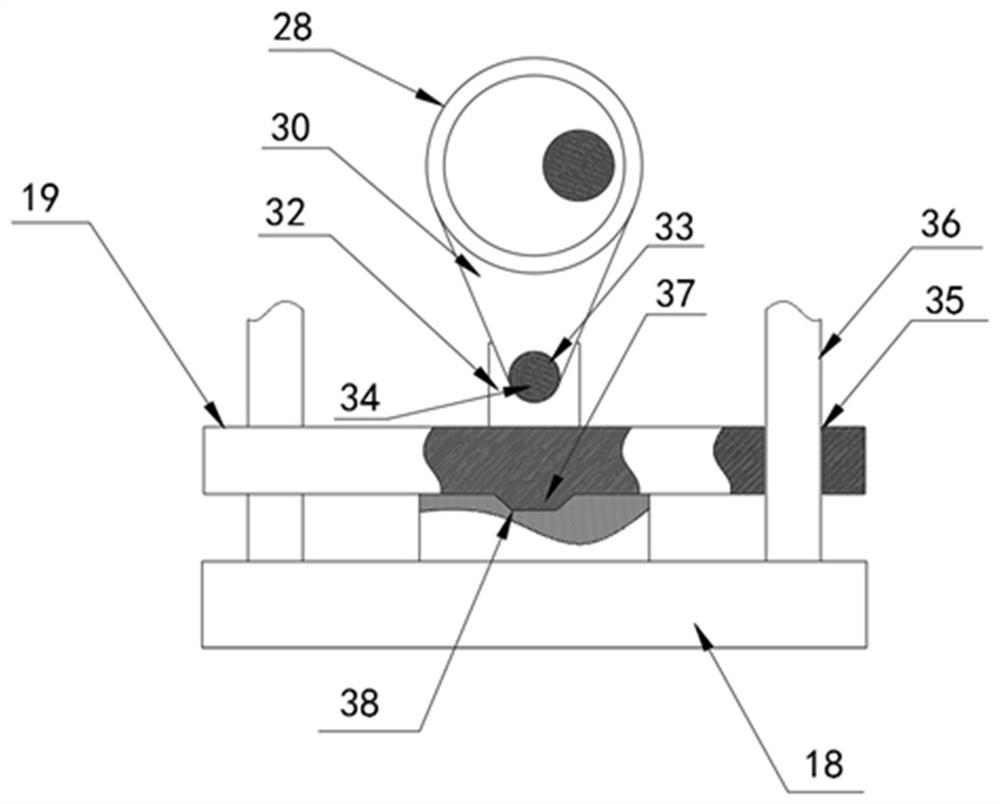

[0047] Such as Figure 1 to Figure 6 As shown, it includes a bracket 1. The bracket 1 includes a beam 2 arranged in parallel. On the upper part of the beam 2, a controller 3, a winding roller 4, a first clamping assembly 5, a reciprocating slide 6, and a paper pulling assembly are arranged sequentially from front to back. 7. Tampering mechanism 8, arc-shaped bottom plate 9, gluing mechanism 10, moxa box 11, second clamping assembly 12, unwinding roller assembly 13, paper feeding roller 14, roll paper holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com