Sliding valve type plunger oil-well pump

A technology of oil well pump and plunger, which is applied in the field of slide valve type plunger oil well pump, which can solve the problems of high cost ratio of valve ball and valve seat, easy occurrence of air lock and sand stuck, and lax valve ball setting, etc., so as to reduce the processing cost cost, saving training and learning costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

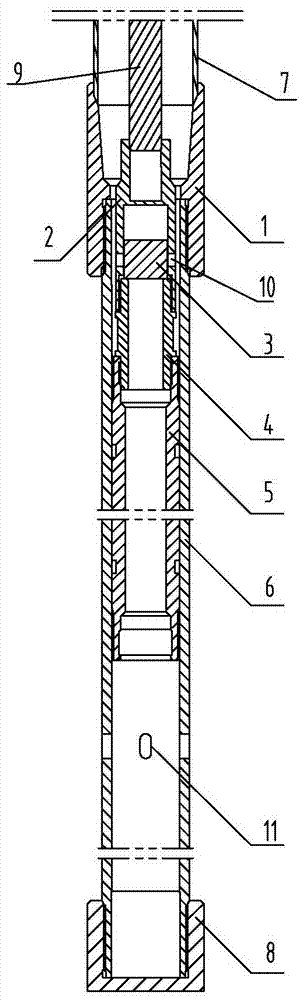

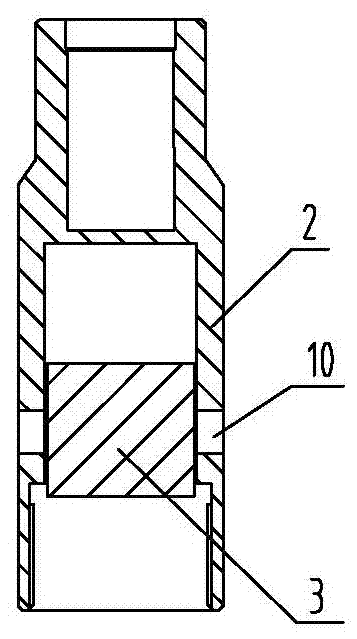

[0009] refer to figure 1 , figure 2 Make the invention. The slide valve plunger oil well pump includes a coupling 1, a double-head threaded joint 4, a plunger 5, a pump cylinder 6 and a plug 8, the upper end of the pump cylinder 6 is fixedly connected to the lower end of the oil pipe 7 through the coupling 1, and the pump cylinder The lower end of 6 is fixedly provided with plug 8, and plunger 5 is arranged in the chamber of pump cylinder 6, and the outer diameter of plunger 5 and the internal diameter of pump cylinder 6 are adapted, and it is characterized in that: the bottom of inner chamber of plunger 5 and The bottom of the inner cavity of the pump cylinder 6 is connected, the upper end of the plunger 5 is fixedly connected with the lower end of the oil outlet cover 2 through the double-ended threaded joint 4, the upper end of the oil outlet cover 2 is fixedly connected with the lower end of the sucker rod 9, and the oil outlet cover 2 The top of the inner chamber is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com