Continuous solid micro thruster

A micro-propeller, continuous technology, used in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems such as poor repeatability of propellers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

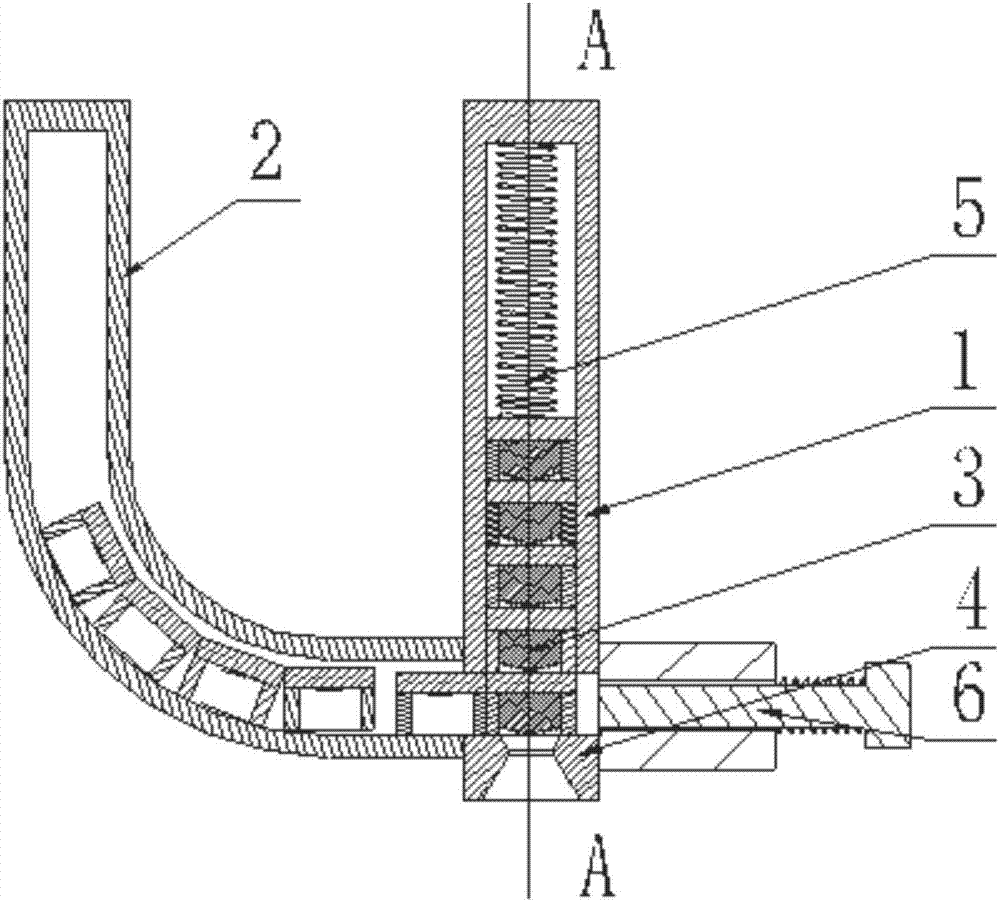

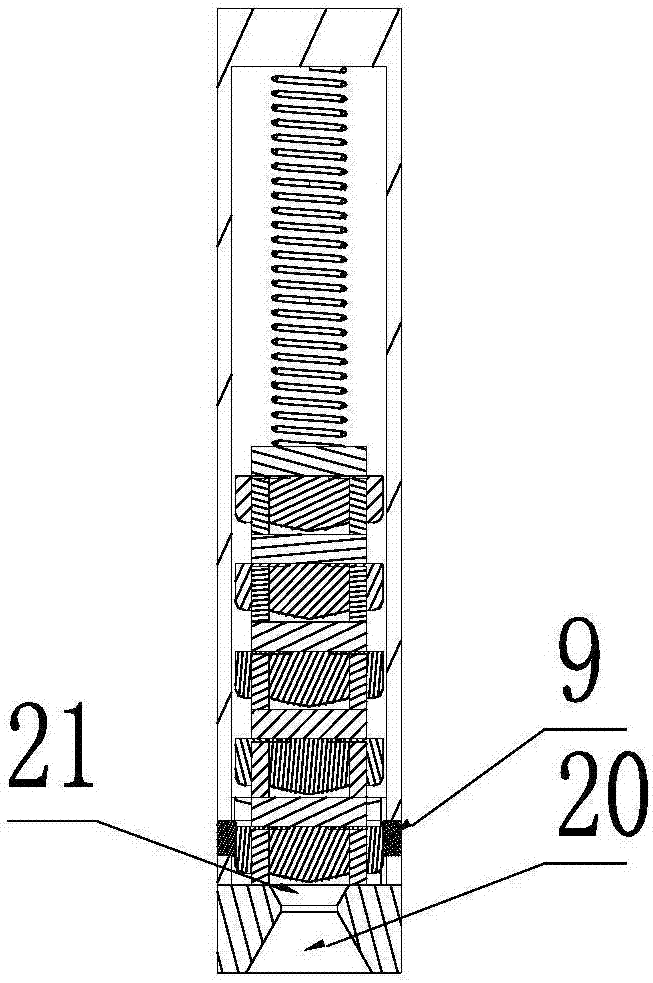

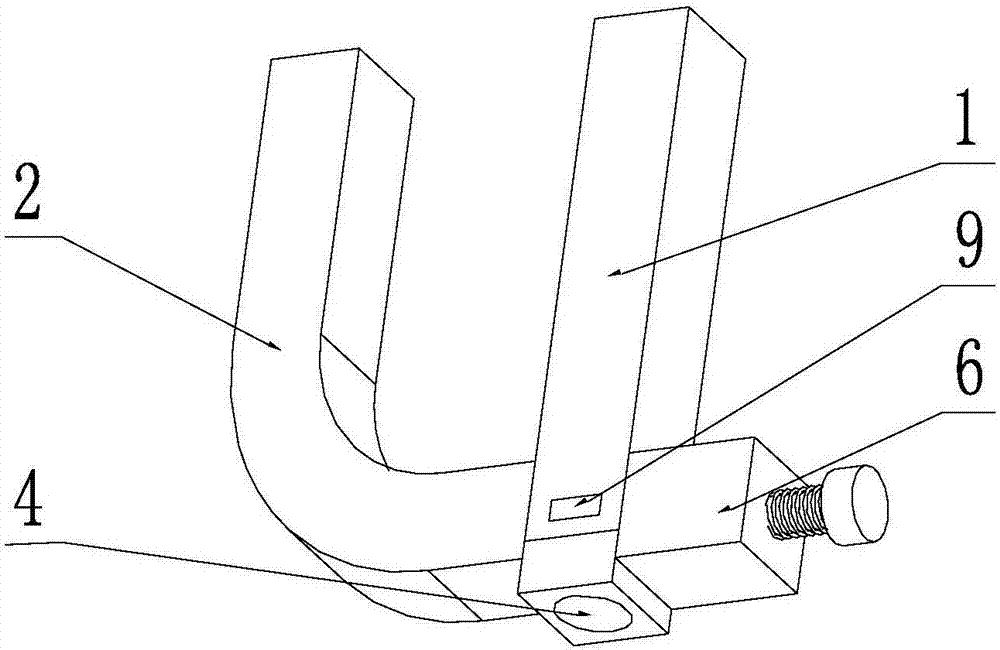

[0038] The invention provides a continuous solid micro-propeller, such as Figure 1-3 As shown, it includes a packaged conduit 1 , a curved conduit 2 , a micro propulsion unit 3 , a nozzle 4 , a compression spring 5 and an electromagnet 6 .

[0039] Such as Figure 4 As shown, the packaging conduit 1 is a rectangular parallelepiped shell structure with a square cross-section, and the inside is a cavity 8 with a square cross-section, the top is sealed, the bottom is an open end, and there are holes penetrating through the two side walls at the bottom of the opposite side walls. The through groove 7, the width of the through groove 7 is consistent with the width of the internal cavity 8 of the packaging conduit 1, and the height is consistent with the height of the micro-propelling unit 3; there are rectangular parallelepiped pads embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com