A particle bed filter and dust removal system

A particle bed filtration and dust removal system technology, applied in the directions of dispersed particle separation, separation methods, chemical instruments and methods, etc., can solve the problems of preventing tar and ash accumulation, blade wear, affecting the sedimentation and discharge of fine dust, etc. The flow fluctuation is small, the temperature difference between the upper and lower sides is reduced, and the effect of promoting dust settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

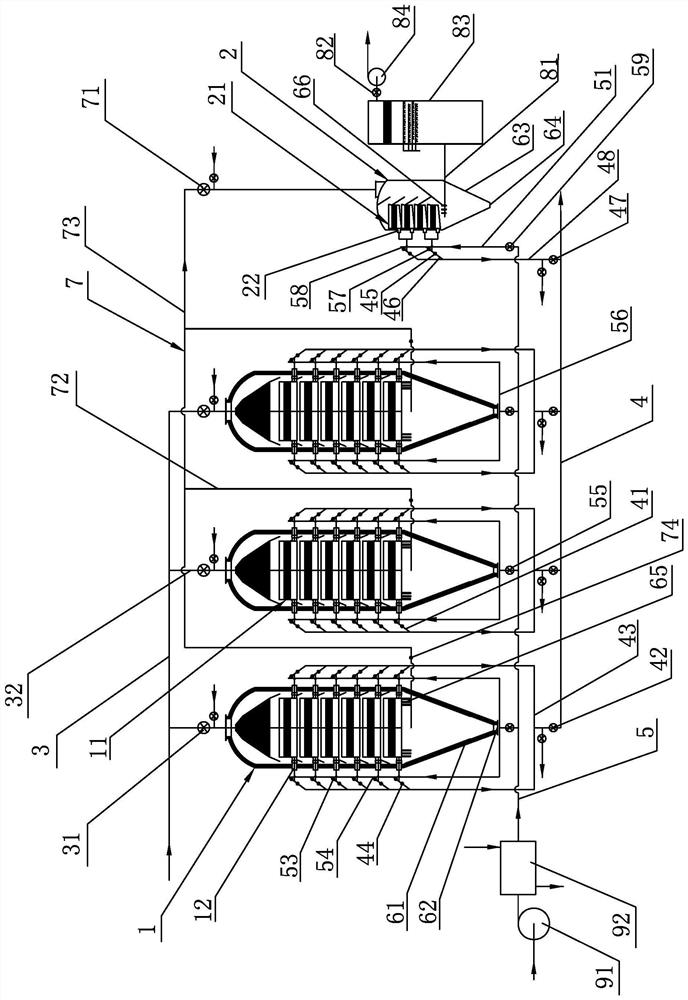

[0031] A particle bed filter dust removal system proposed in this embodiment, such as figure 1 As shown, it includes three main particle bed filter dust collectors 1, a secondary particle bed filter dust collector 2, a dust-laden gas main pipe 3, a clean gas main pipe 4 and a backflushing gas main pipe 5, and a main particle bed filter dust collector 1. There are twelve main particle beds 11 with six layers and two in each layer. The top of the main particle bed filter dust collector 1 is connected with the dust-containing gas main pipe 3. Specifically, the dust-containing gas main pipe 3 is connected in series with the main dust-containing gas. The main dust-laden gas intake branch pipe 32 of the intake valve 31 is communicated with the top of the main particle bed filter and dust collector 1, and the dust-laden gas main pipe 3 conveys dust-laden gas to the main particle bed filter and dust collector 1, and the main particle bed filter and dust collector 1. 1 are respectively...

Embodiment 2

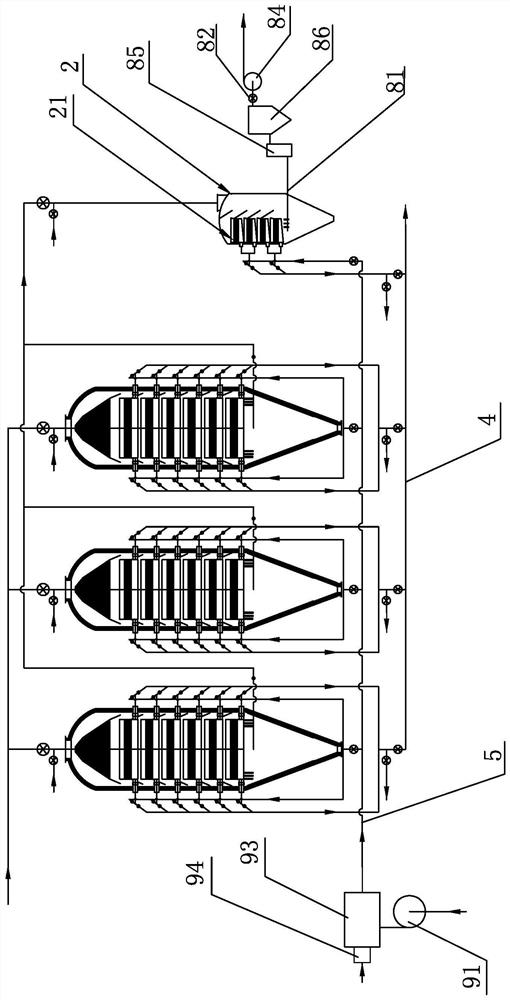

[0040] A particle bed filter dust removal system proposed in this embodiment, such as figure 2 As shown, the structure is basically the same as that of the particle bed filtration and dust removal system of the first embodiment, the only difference is that a reverse blower 91 is connected to the upstream of the reverse blowing gas main pipe 5, and the inlet end of the reverse blower 91 is fed with clean air. During processing, the inlet end of the reverse blower 91 is communicated with the outlet end of an external clean air induced draft fan (not shown) or communicated with an external clean air cabinet to introduce clean air, and the outlet end of the reverse blower 91 is connected to the reverse blowing gas main pipe A mixer 93 for mixing clean gas and high-temperature flue gas is arranged between the inlet ends of 5. The mixer 93 is connected with a burner 94 that provides high-temperature flue gas. To meet the required temperature, in order to reduce the mixing amount of...

Embodiment 3

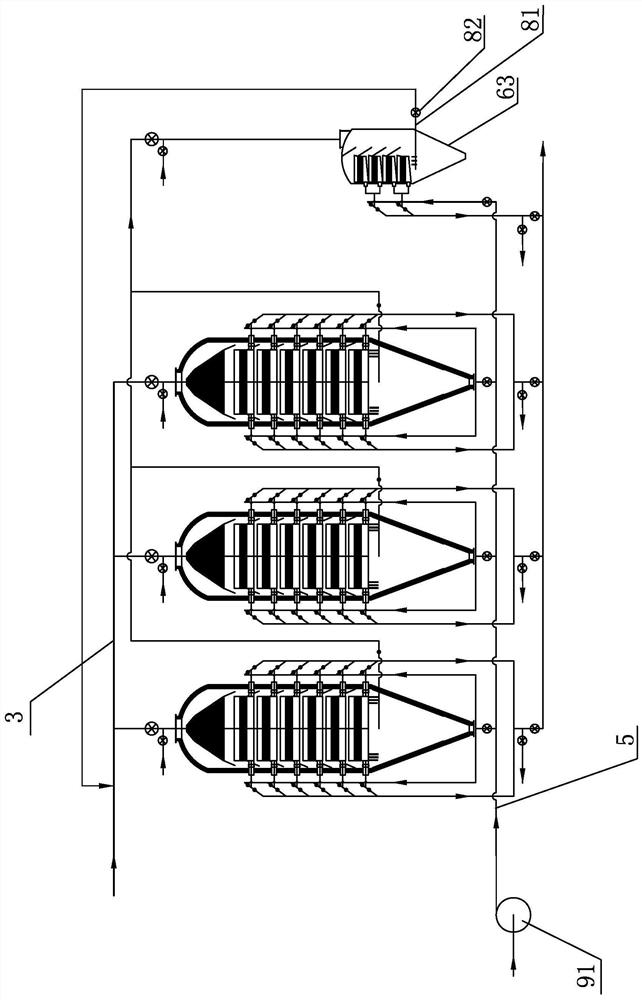

[0043] A particle bed filter dust removal system proposed in this embodiment, such as image 3 As shown, it is basically the same as the structure of the particle bed filtration and dust removal system of the first embodiment or the structure of the particle bed filtration and dust removal system of the second embodiment, the difference is only that: the upstream of the reverse blowing gas main pipe 5 is connected with a reverse blower 91, The inlet end of the reverse blower 91 is fed with high-temperature flue gas. In actual processing, the inlet end of the reverse blower 91 is connected with the high-temperature flue gas pipeline (not shown in the figure), and the high-temperature flue gas is directly fed into it, so that the temperature meets the requirements of backflushing. The high temperature flue gas is used as backflush gas. The outlet end of the dust-laden backflushing gas outlet pipe 81 is connected in series with the outlet valve 82 and then connected to the dust-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com