Automatic energy storage high pressure liquid injection co2 phase change pulse coal rock mass fracturing device

A coal rock mass and high-pressure liquid storage technology, applied in the field of CO2 phase change pulse fracturing solid device, can solve the problems of easy collapse of boreholes, small fracturing range, and short continuous injection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below.

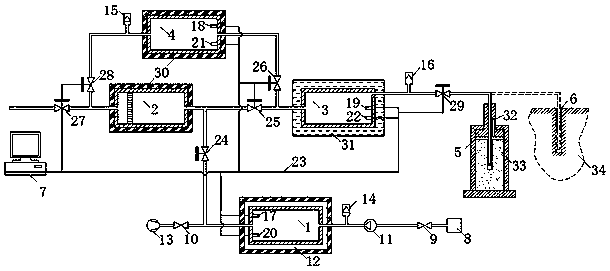

[0032] As described in the accompanying drawings, implementing the CO provided by the present invention for automatic energy storage and high-pressure injection 2 Phase change pulse solid fracturing device, which consists of four parts: liquid supply system, automatic energy storage high-pressure liquid injection system, phase change fracturing system, data acquisition and control system. The liquid supply system includes liquid CO 2Source 8, liquid booster pump 11, high pressure liquid storage temperature control tank 1, cooling box 12 and vacuum pump 13; the described automatic energy storage high pressure liquid injection system includes high pressure liquid injection cylinder 2, energy storage chamber 4, phase change chamber 3 And oil bath 31; Described phase change fracturing system includes phase change chamber 3, oil bath 31, fracturing chamber 5, and fracturing body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com