Manual drilling machine having drill pin protection function

A protection function and manual punching technology, which is applied in the field of punching machines, can solve problems such as adjustment and easy deformation, and achieve the effect of preventing distortion and deformation and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

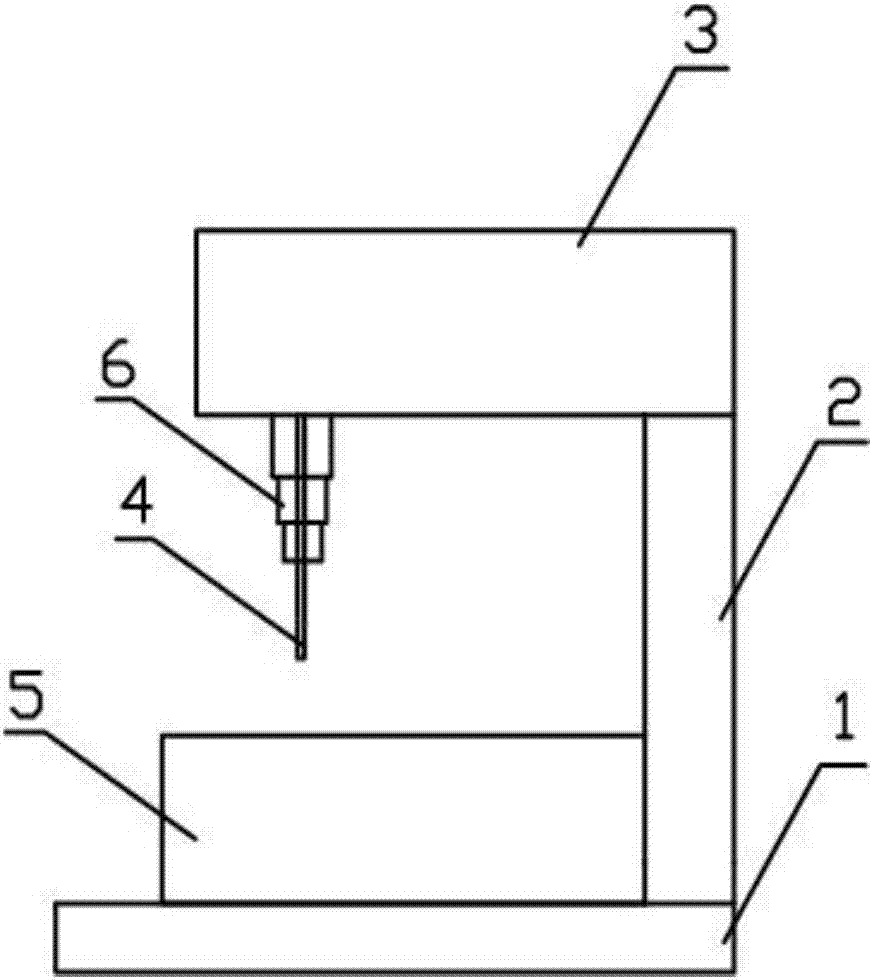

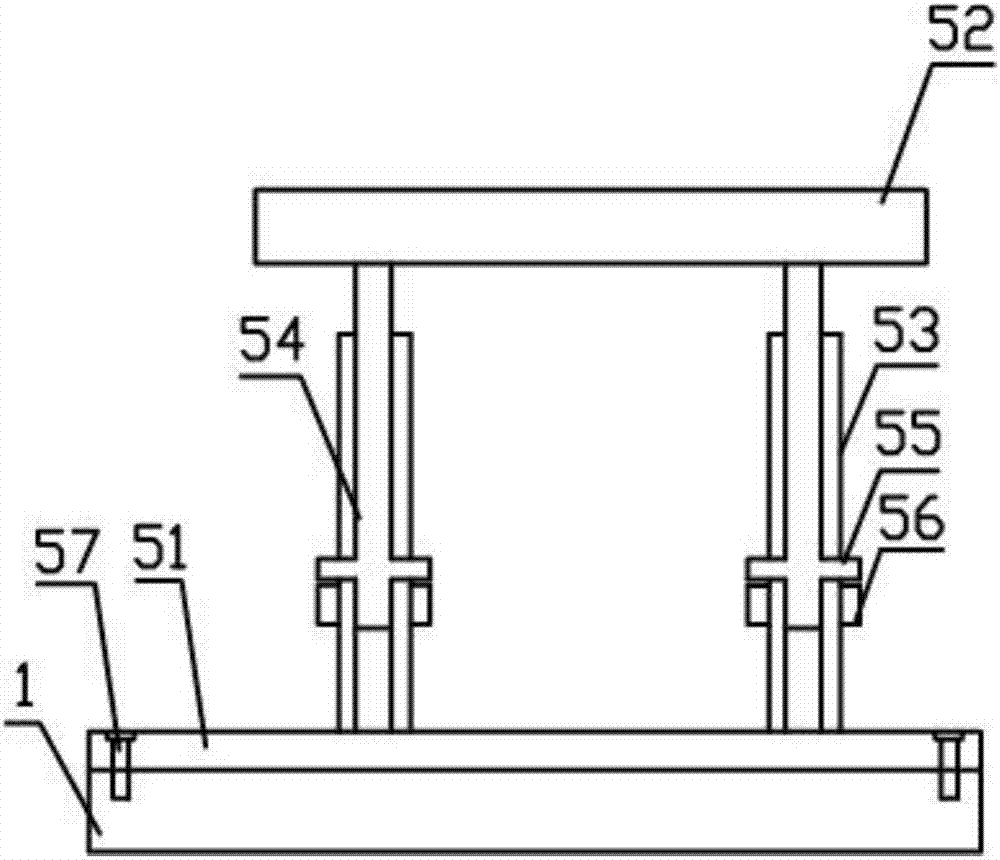

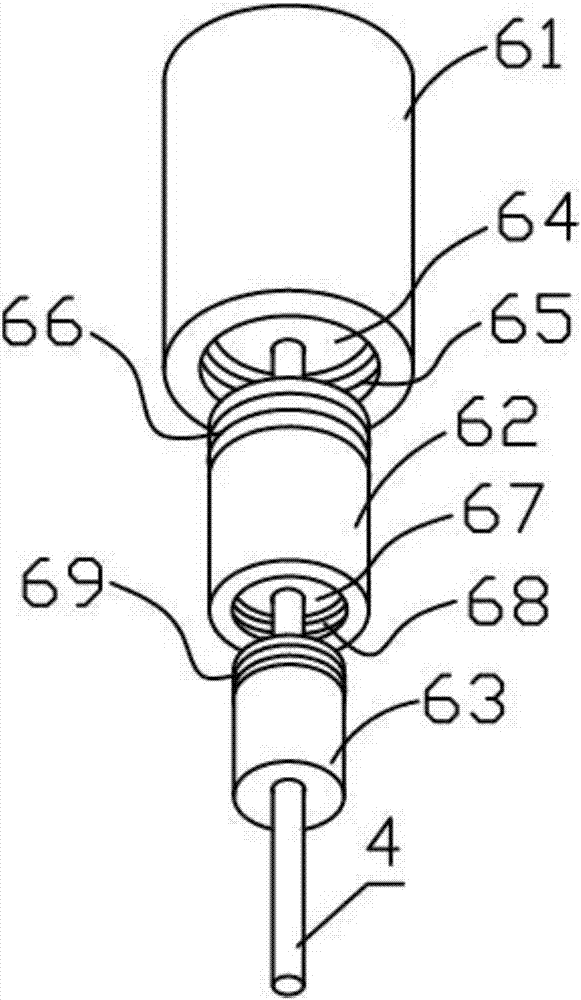

[0027] Such as figure 1As shown, the present invention is a manual punching machine with drill needle protection function, including a base 1 and a support rod 2, one axial end of the support rod 2 is fixed on the base 1, and the other axial end of the support rod 2 is installed with a machine head 3. A drill 4 is provided on the machine head 3 . The base 1 is also provided with a height adjustment mechanism 5, the height adjustment mechanism 5 includes a lower base plate 51, the lower base plate 51 is fixed on the base 1, the lower base plate 51 is welded with a fixed pipe 53, and the axis of the fixed pipe 53 is perpendicular to the lower base plate 51. On the board surface, two symmetrical and continuous slide grooves are provided on the side wall of the fixed pipe 53 along the axial direction. A movable strut 54 is set inside the fixed tube 53, and one end of the movable strut 54 is located in the fixed tube 53, and two symmetrically arranged limiting strips 55 are protru...

Embodiment 2

[0029] Further improvement on the basis of Embodiment 1, the present invention is a manual punching machine with a drill pin protection function, which is uniformly provided with fixed pipes 53, the cross section of the lower bottom plate 51 is a rectangular structure, and four fixed pipes 53 are symmetrically distributed on the bottom At the four corners of the bottom plate 51, and each fixed pipe 53 is provided with the adjustment ring 56, the adjustment rings 56 on different fixed pipes 53 are connected by transmission belt transmission, and four adjustment rings 56 can be connected by one transmission belt. Only one of the adjustment rings 56 needs to be acted on by an external force to drive the other three adjustment rings 56 to rotate through the conveyor belt.

Embodiment 3

[0031] Further improvement on the basis of Example 2, the present invention is a manual punching machine with drill needle protection function, four threaded through holes are provided on the edge of the lower bottom plate 51, and the base 1 is provided with the same The fixed threaded hole used in conjunction with the above-mentioned threaded through hole, the lower bottom plate 51 is fixed on the base 1 through the countersunk bolt 57 passing through the threaded through hole and the fixed threaded hole in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com