Wiring harness support

A wire harness bracket and bracket seat technology is applied in the field of wire harnesses, which can solve the problems of small wire harness openings and inability to meet requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

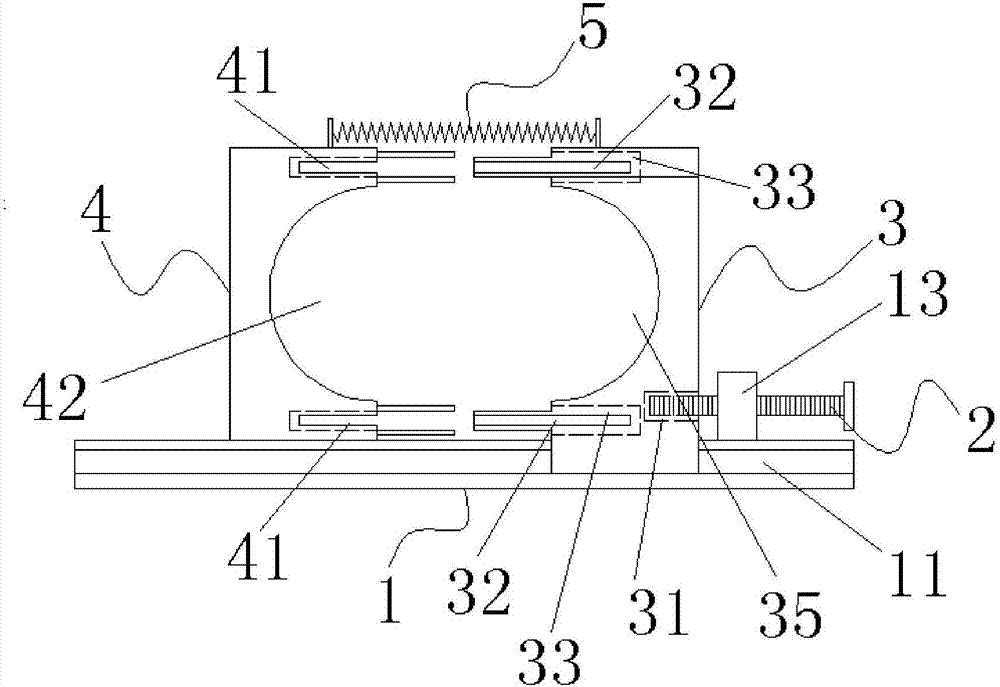

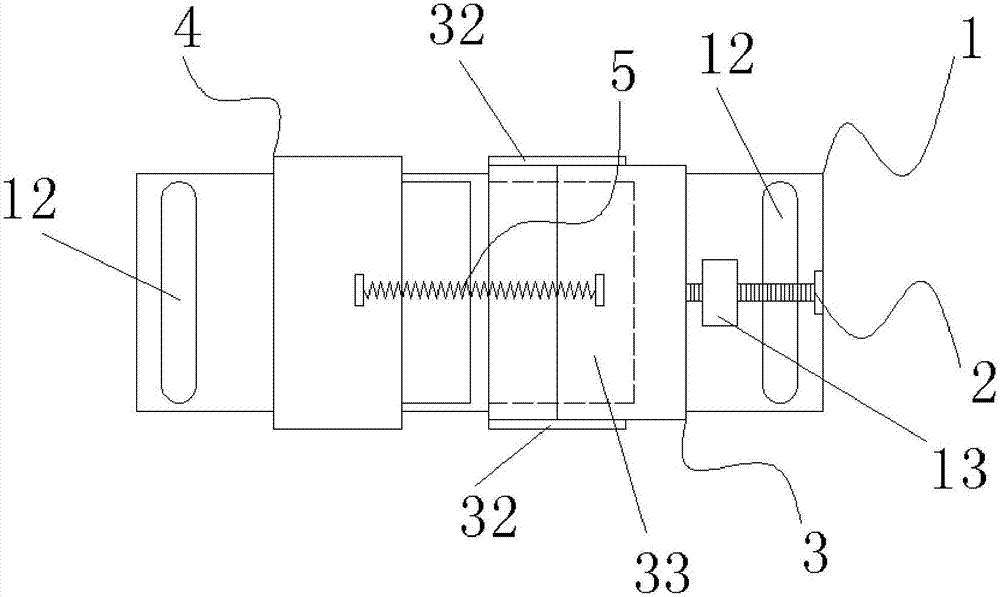

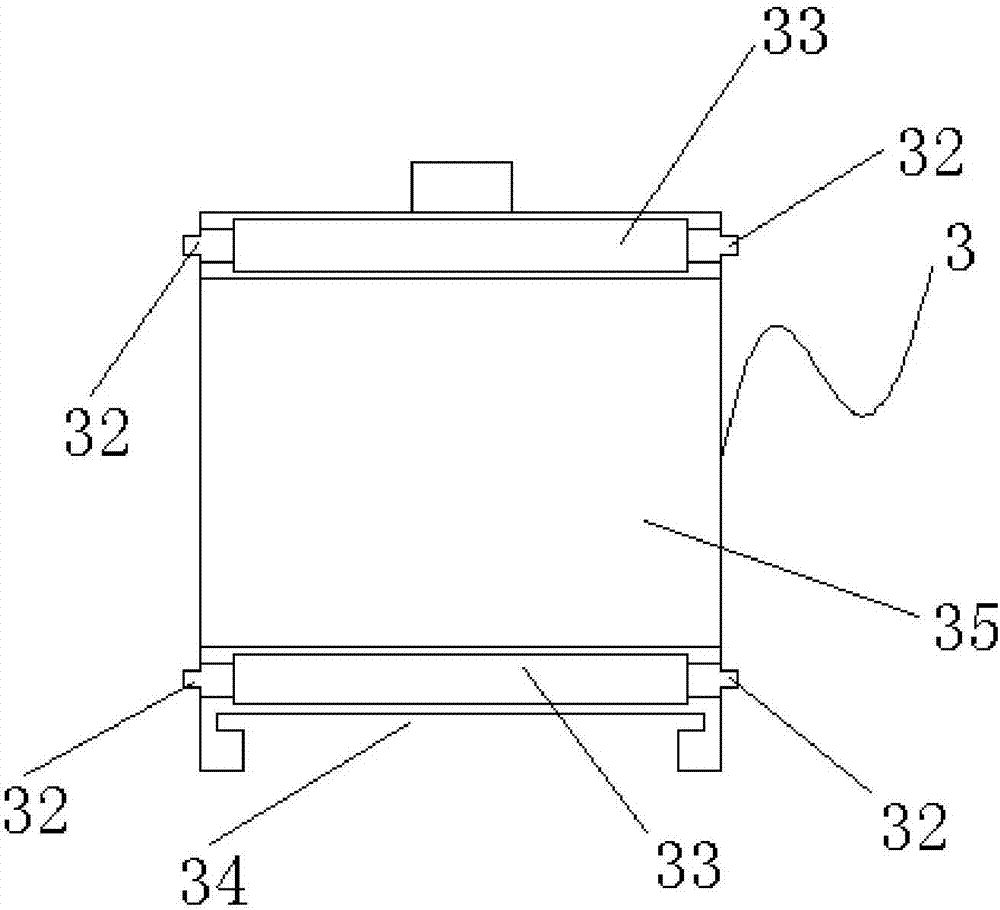

[0020] This invention is a wire harness bracket, which can be fixed on the body frame through the fixing grooves 12 on both sides of the bracket seat 1 with screws. Withdraw from the pole seat 13, and then slide the main harness cover 3 out of the bracket base 1 through the chute 34 along the slide rail 11, then put the wire harness in the auxiliary wire harness opening 42, and then put the main harness cover 3 through the chute 34 along the The slide rail 11 slides into the bracket seat 1, at this time, the wire harness is clamped in the main wire harness port 35 and the auxiliary wire harness port 42, and then the threaded ejector rod 2 is twisted into the threaded ejector rod seat 13, and the threaded ejector rod 2 touches the ejector rod groove 31 Finally, continue to screw in the threaded mandrel 2, and the threaded mandrel 2 will slide to the left against the main wire harness sleeve 3, and the front end of the main wire harness sleeve 3 will be inserted into the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com