Mechanism for preventing car seat lock failure and peeling of upper and lower slide rails

A car seat slide rail and slide rail technology, which is applied to vehicle seats, movable seats, special positions of vehicles, etc., can solve the problems of slide rail locking failure and peeling, and achieve reliable sliding function and low manufacturing cost , good protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

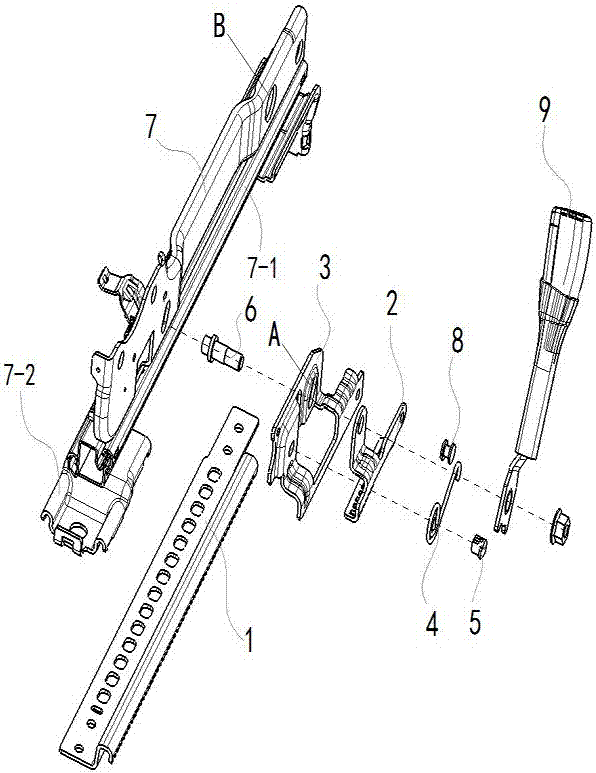

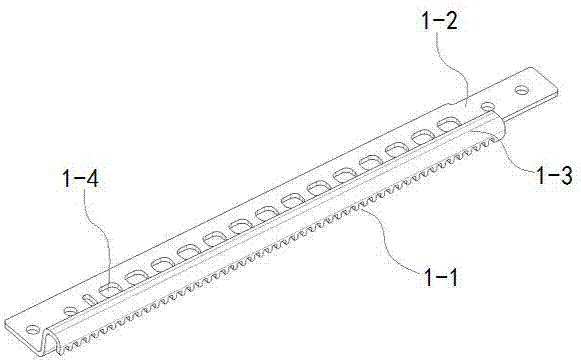

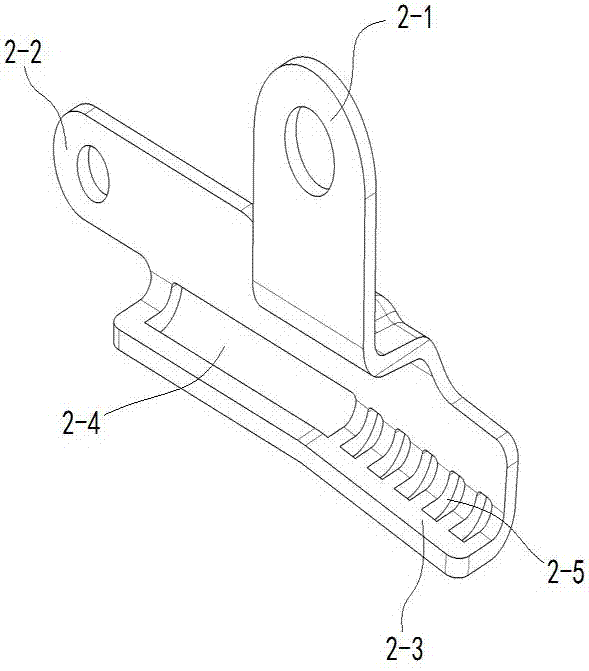

[0017] By the attachment figure 1 , 2 , 3, 4, and 5: The mechanism includes the slide rail reinforcement plate 1, the anti-drop gear plate 2, the fixing bracket 3, the retaining spring 4, the spring fixing cotter pin 5, the seat belt fixing bolt 6, the side plate assembly 7 and Rivet 8, the slide rail reinforced version 1 is fixed between the slide rail 7-1 and the foot 7-2 of the side plate assembly 7, and the fixing bracket 3 is welded to the side plate assembly 7 as a whole to prevent the tooth plate from falling off 2 is connected to the fixed bracket 3 through a rivet 8 and can rotate around the rivet 8; one end of the retaining spring 4 is mounted on the fixed bracket 3 through a spring-fixed split pin 5, and the other end is hung on the seat belt fixing bolt 6; The bracket 3 has an oval hole A, and the side plate assembly 7 has the same oval hole B at the position corresponding to the oval hole A. When the fixing bracket 3 and the side plate assembly 7 are welded, the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com