Electric heating element electrifying board

A technology of electric heating element and energized board, applied in the direction of electrical elements, circuits, contact parts, etc., can solve the problems of difficulty in meeting production requirements, difficult to disassemble, and low efficiency of plug-in terminal wiring, so as to improve wiring efficiency and simplify control logic. and control circuit to realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide an electric heating element energizing plate to improve the wiring efficiency of the plug-in terminal.

[0030] Hereinafter, embodiments will be described with reference to the drawings. In addition, the embodiments shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configuration shown in the following embodiments are not limited to what is necessary as a solution to the invention described in the claims.

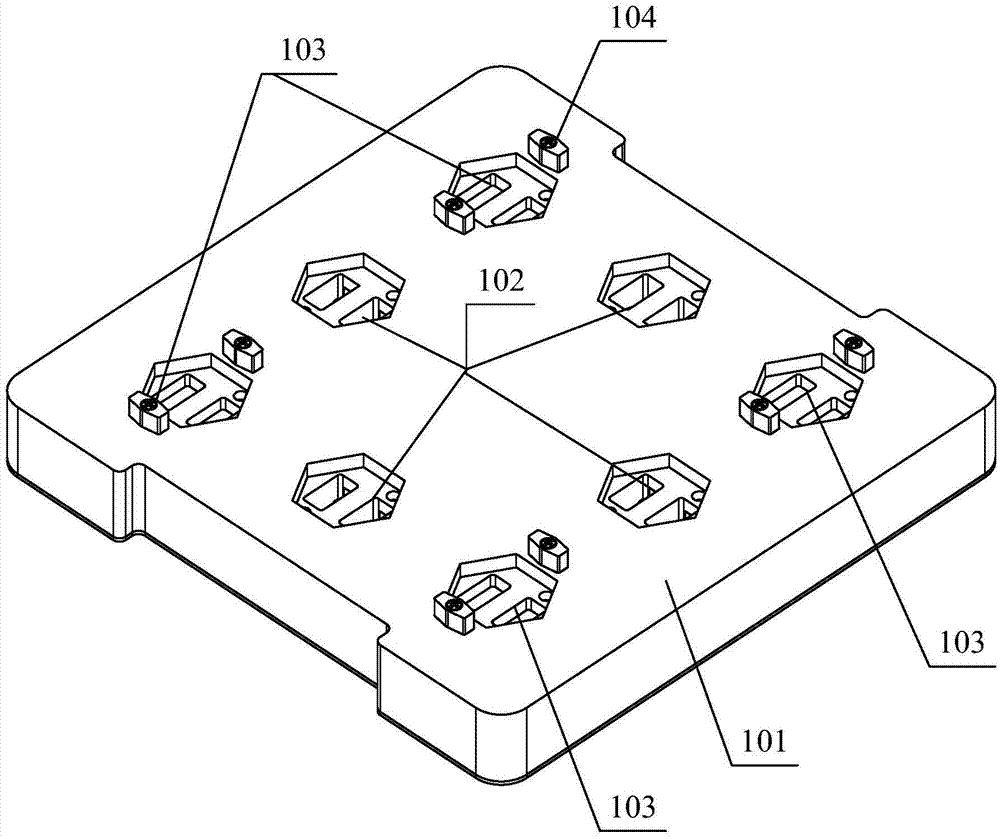

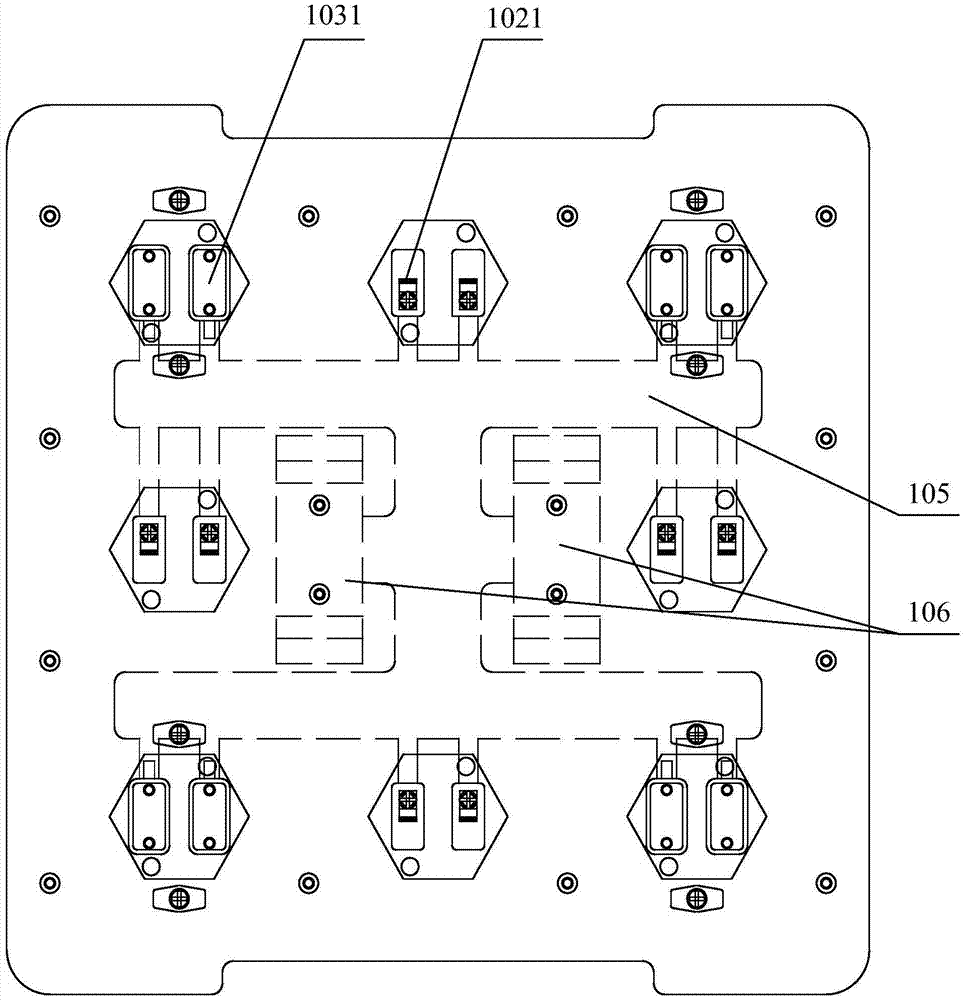

[0031] See figure 1 with figure 2 , figure 1 Is a schematic diagram of the structure of an electric heating element energizing plate provided by an embodiment of the present invention; figure 2 It is a top view of the energizing plate of an electric heating element provided by an embodiment of the present invention.

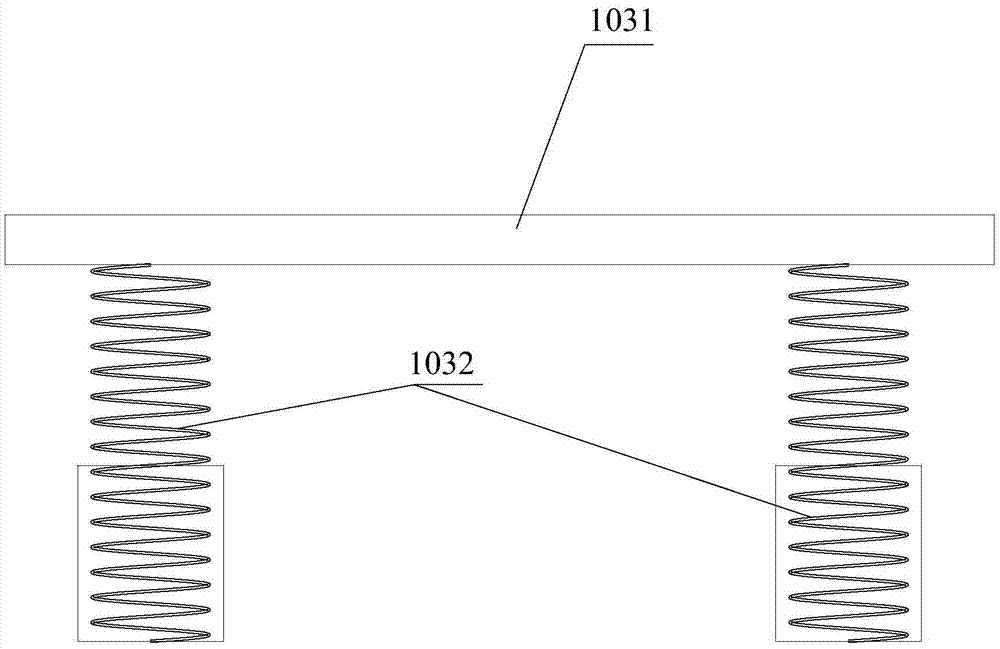

[0032] The electrical heating element energizing plate provided by the embodiment of the present invention includes an energizing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com