Control valve assembly

一种控制阀、组件的技术,应用在发动机元件、机器/发动机、装料系统等方向,能够解决泄漏路径增大、增大燃料泄漏量与燃料喷射量、泄漏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention is described below in terms of its orientation in the figures; references to upper, lower, above and below are not intended to be limiting.

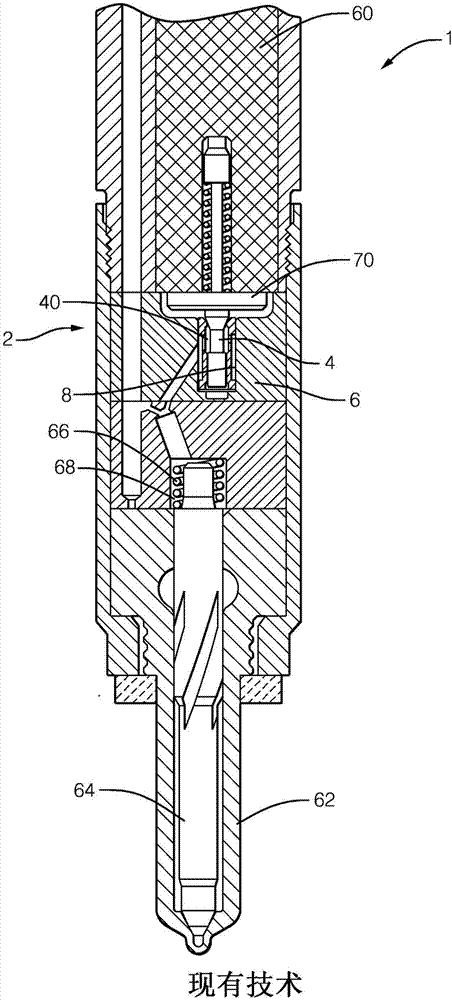

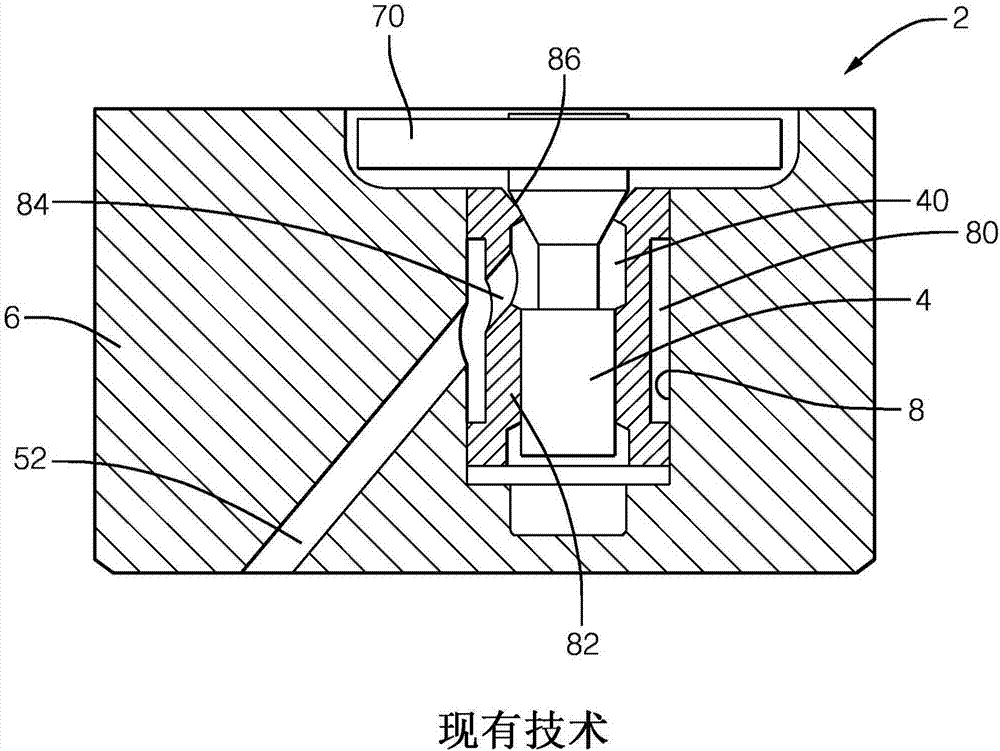

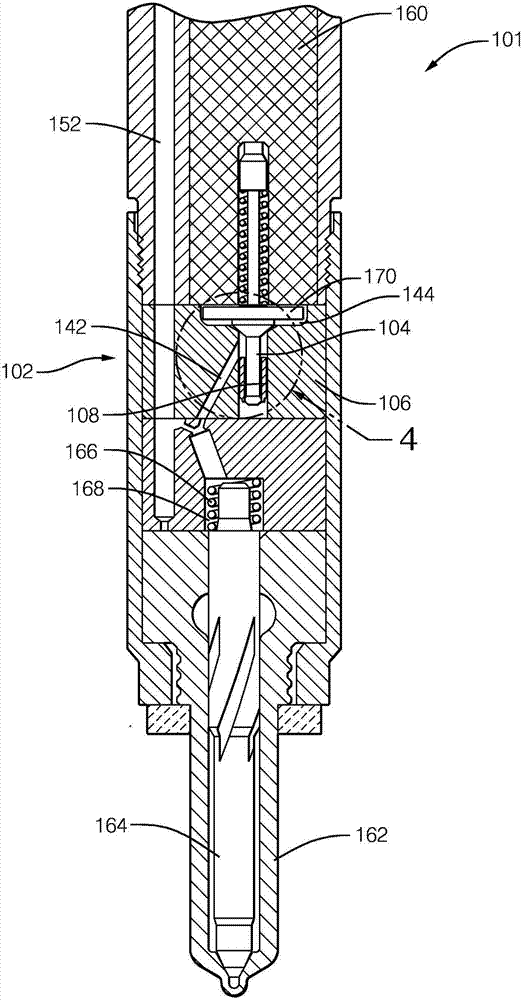

[0023] refer to image 3 with Figure 4 , the injector 101 includes an injector body 160 , an injector nozzle 162 , a movably mounted injector needle 164 , and a control valve assembly 102 .

[0024] The injector 101 has a longitudinal axis A; with respect to the longitudinal axis A references to "axial" and "radial" are made below.

[0025] A spring 166 is disposed in the spring chamber 168 to bias the injector needle 164 toward a seated position in which fuel is prevented from being combusted via one or more spray holes (not shown) provided in the injector nozzle 162. A chamber (not shown) is injected. Under the control of the control valve assembly 102, the injector needle 164 can be moved to an open position wherein fuel can be injected through the spray orifice.

[0026] The control valve assembly 102 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com