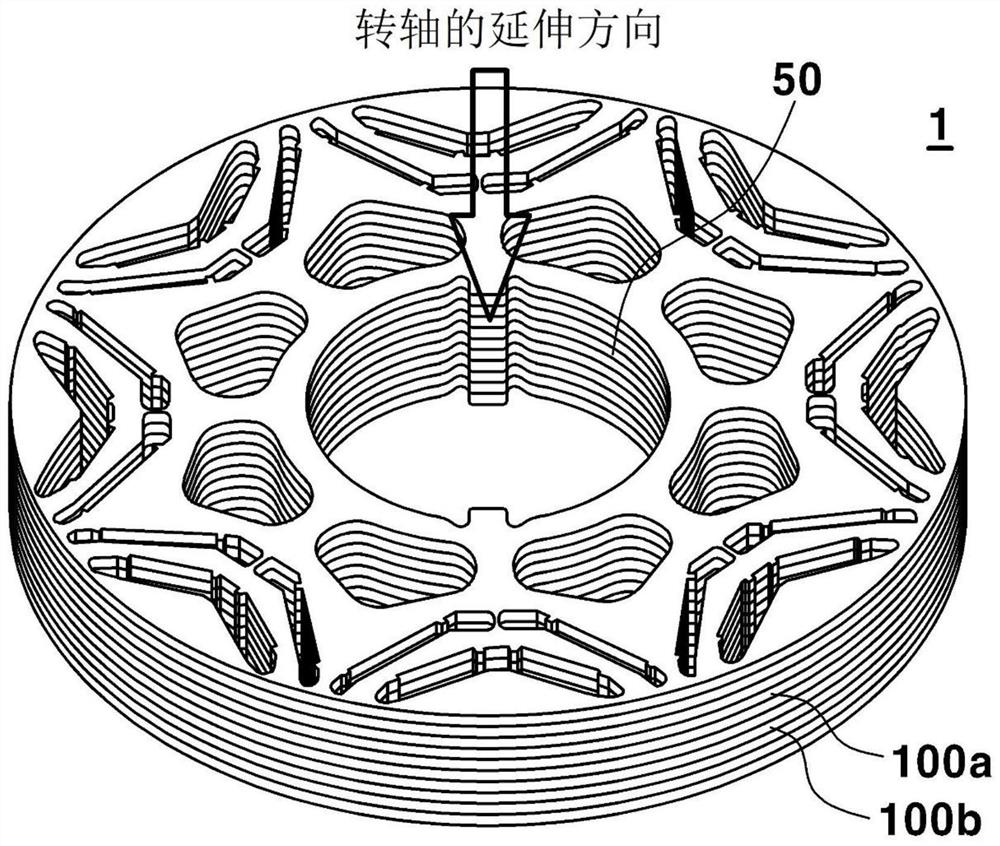

Rotor for application in drive motor

A technology for driving motors and rotors, which is applied in the field of rotors with stacked rotor cores, which can solve the problems of reduced torque density, reduced performance of driving motors, and reduced efficiency, and achieve the effects of minimizing leakage, reducing quantity, and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

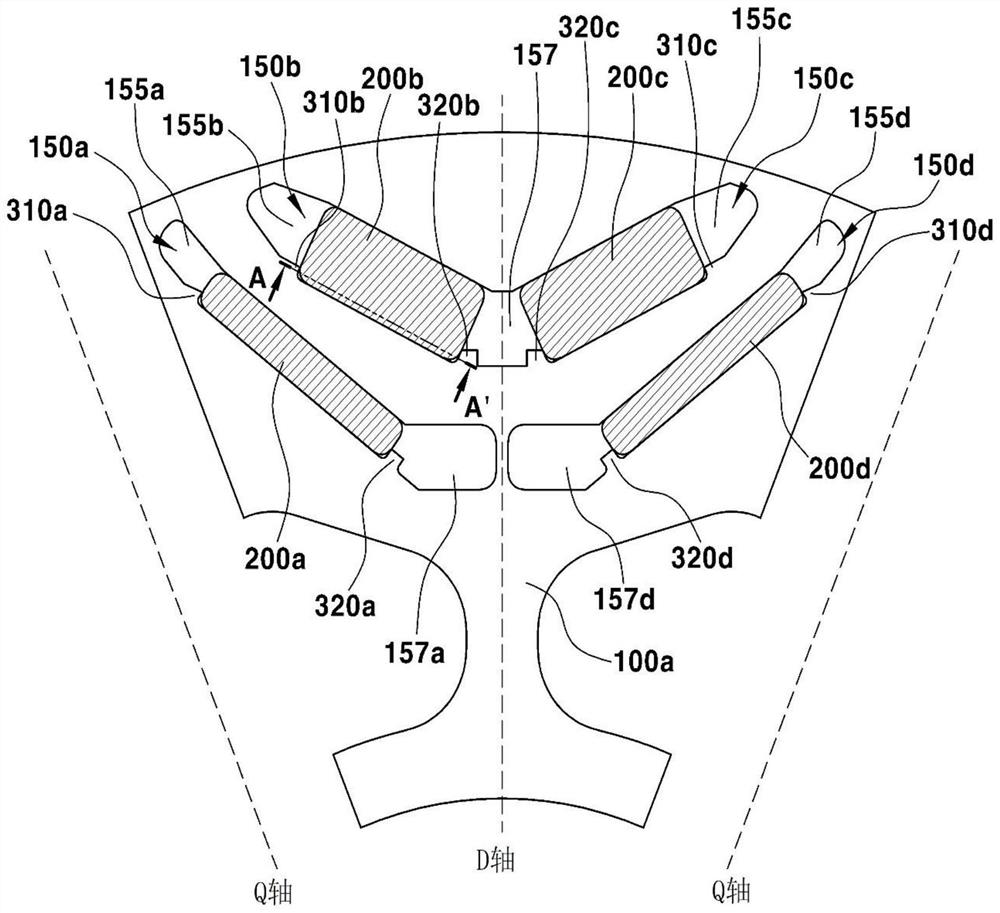

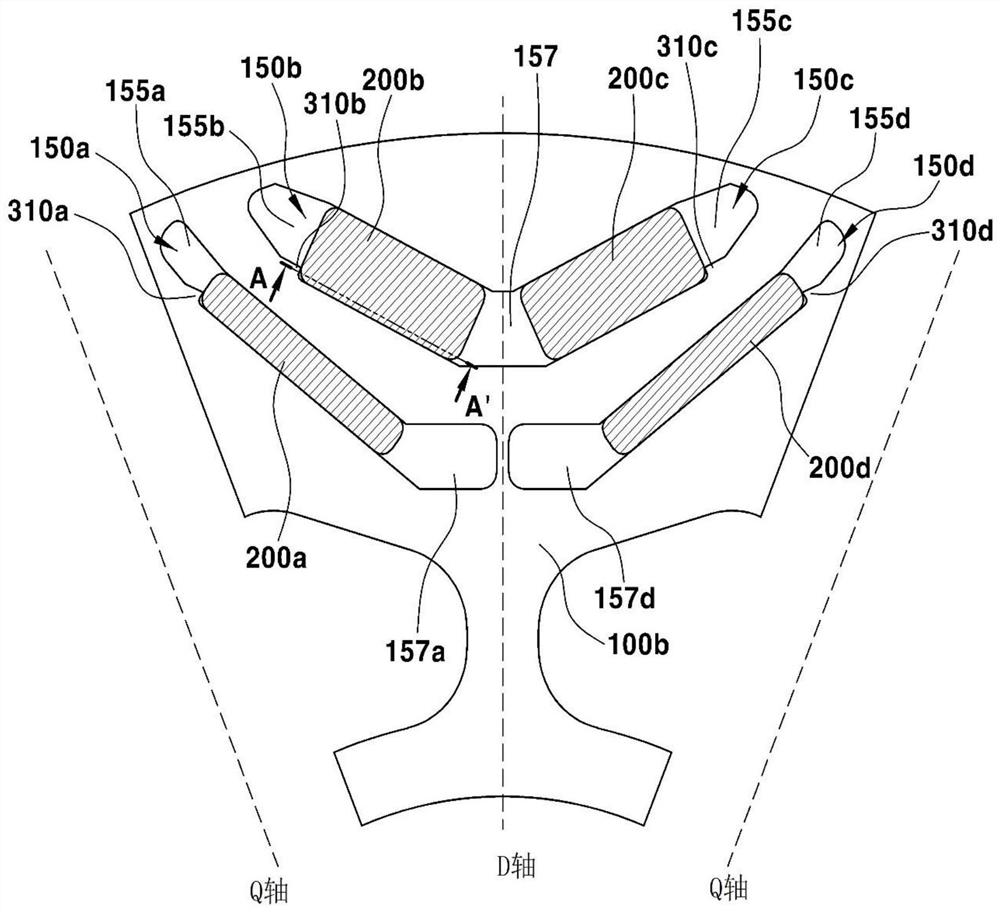

Embodiment Construction

[0028] Advantages and features of the present disclosure and a method of achieving the advantages and features will be apparent from the accompanying drawings and the embodiments to be described in detail below. However, the present disclosure is not limited to the embodiments to be disclosed below, and can be implemented in various embodiments. The embodiments are provided in order to fully disclose the present disclosure and to clearly understand the scope of the present disclosure to those having ordinary skill in the art to which the present disclosure pertains. However, the scope of the present disclosure should be limited only by the claims. The same reference numerals refer to the same constituent elements throughout the specification.

[0029] Also, the terms first, second, etc. are used throughout this specification in order to distinguish constituent elements having the same name. In the following description, it is not necessary to impose any limitation on the ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com