Method and device for operating a pump

A technology of pump pipelines and actuators, which is applied in the direction of measuring devices, fuel injection devices with sensors, pump parameters, etc., can solve problems such as unavailability, and achieve the effect of small space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

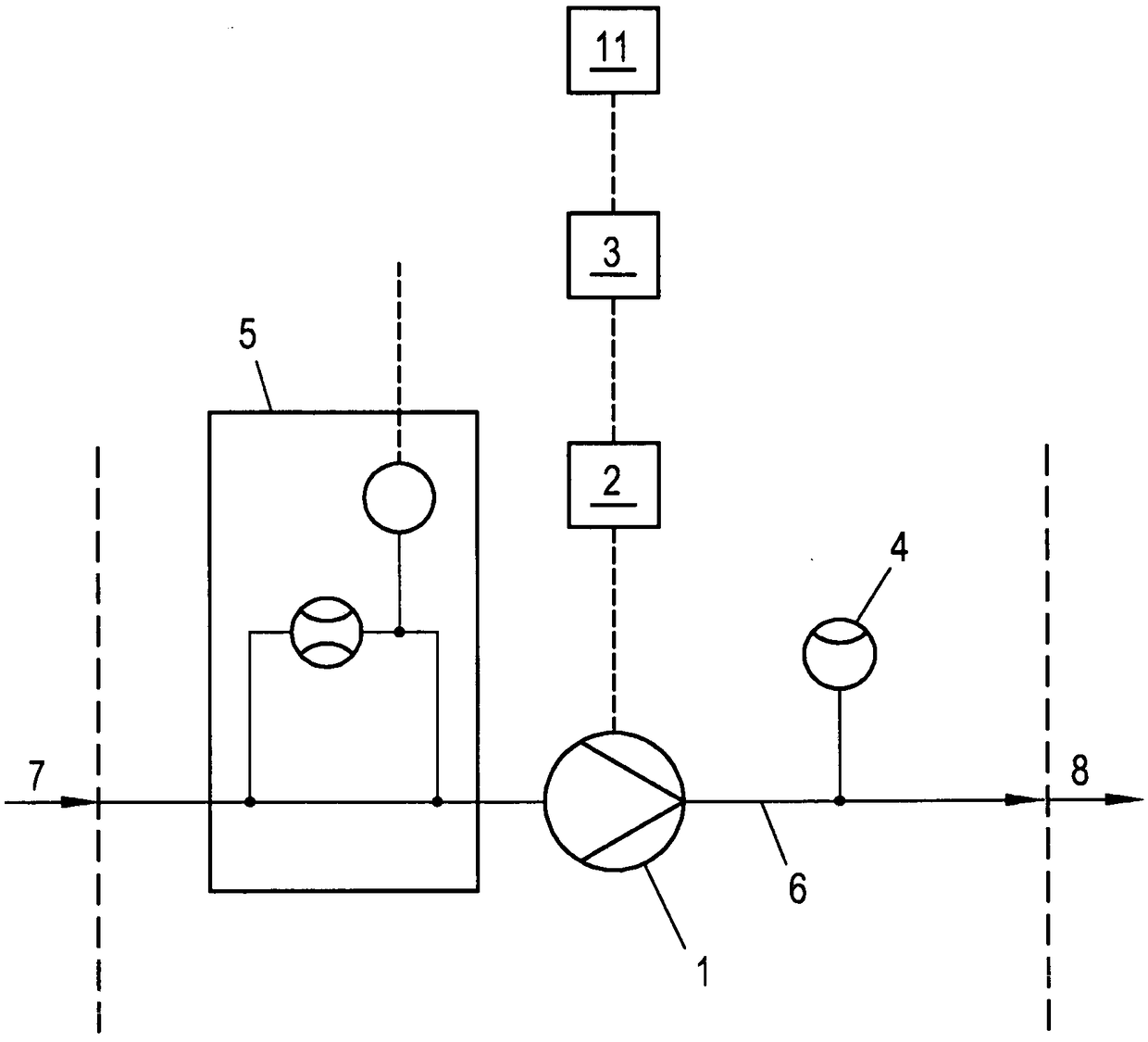

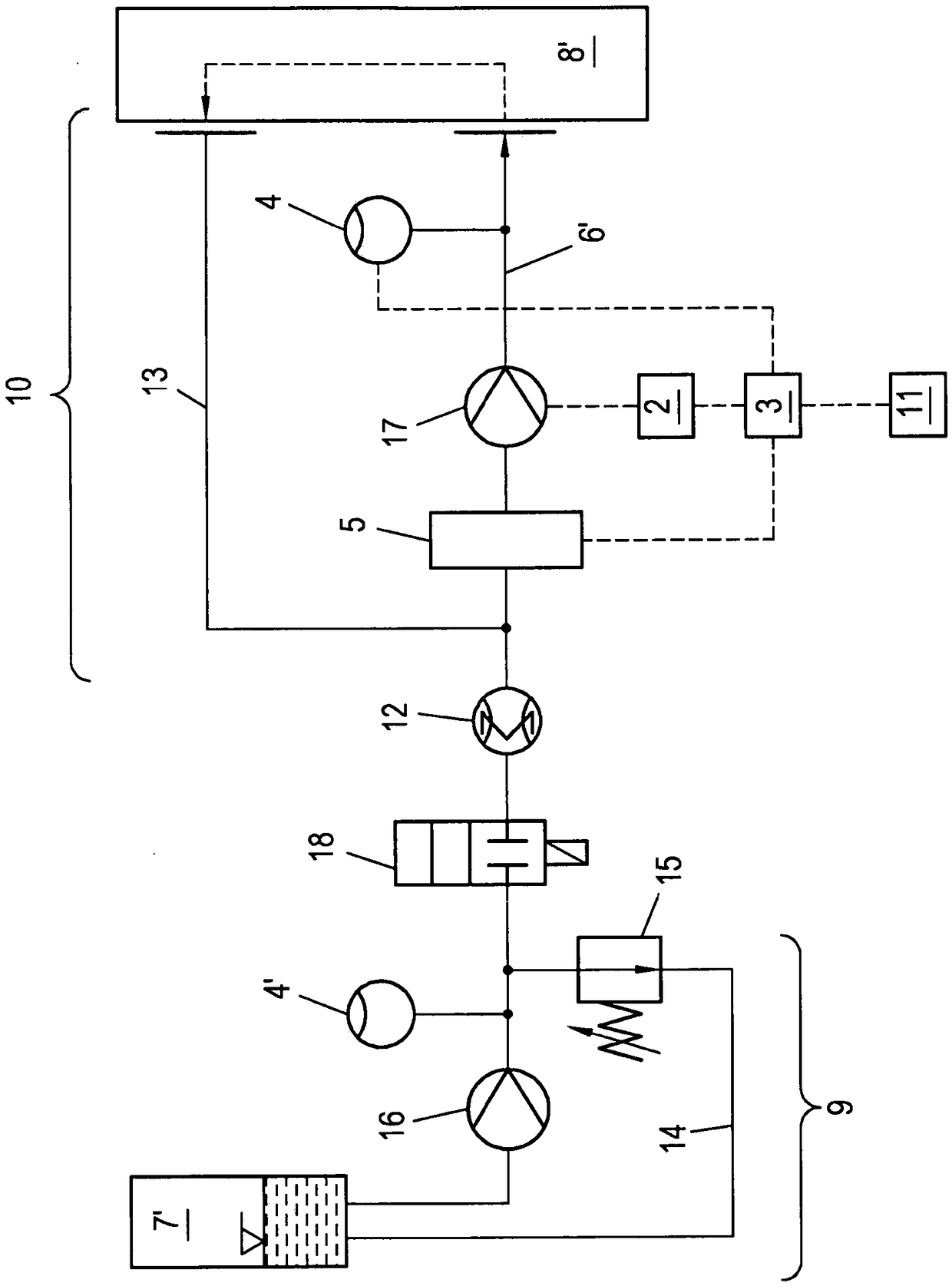

[0039] figure 1 The device according to the invention is shown in a simplified schematic diagram, in which a pump 1 pumps the medium to be pumped in a pump line 6 from a medium source 7 to a medium consumer 8 . In connection with the specific description, the line in which the pump is arranged is referred to as "pump line" and through which the pump pumps the medium to be pumped. The pump line can also be led in a circulation circuit, as is usual, for example, in heating systems.

[0040] The pump 1 is connected to an actuator 2 , wherein the actuator 2 predetermines a control variable which determines the delivery performance of the pump 1 . The control variable can be, for example, a frequency, and the actuator 2 can be a frequency converter.

[0041] A density sensor 5 is arranged upstream of the pump in the pump line 6 , wherein a viscosity sensor can also be provided instead of the density sensor 5 or in addition to the density sensor.

[0042] A flow controller 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com