Grinding device and grinding method thereof

A grinding device and grinding method technology, applied in the direction of grinding devices, grinding machine tools, grinding tools, etc., can solve the problems of uneven grinding efficiency and quality, large manufacturers, etc., to reduce the total thickness variation, increase production, and increase economy effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Various embodiments of the present invention will be described below with reference to the drawings. For the sake of clarity, many practical details are included in the following narrative. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the present invention, these practical details are unnecessary. In addition, for the sake of simplifying the drawings, some existing conventional structures and elements will be shown in a simple schematic manner in the drawings; and repeated elements may be denoted by the same numbers.

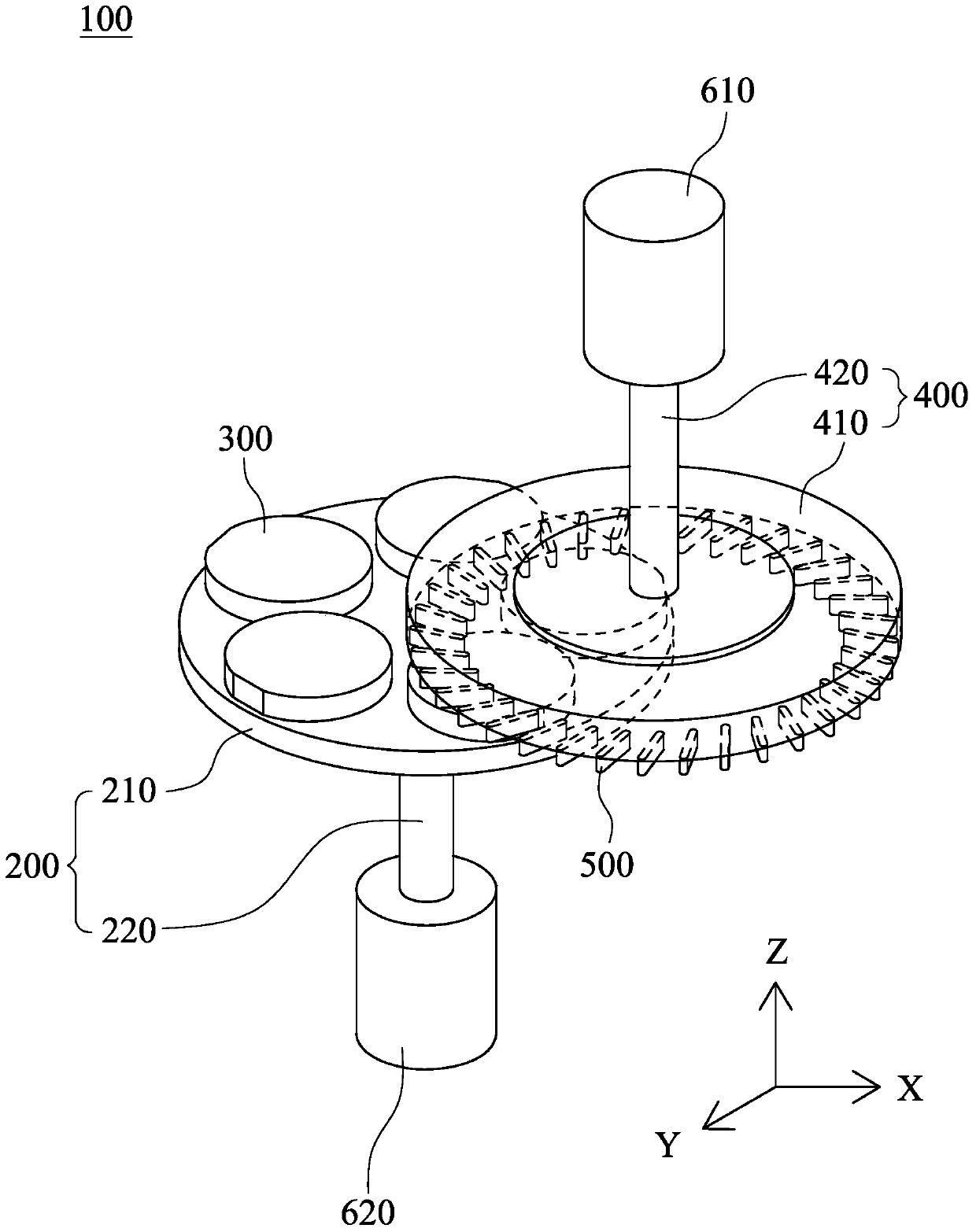

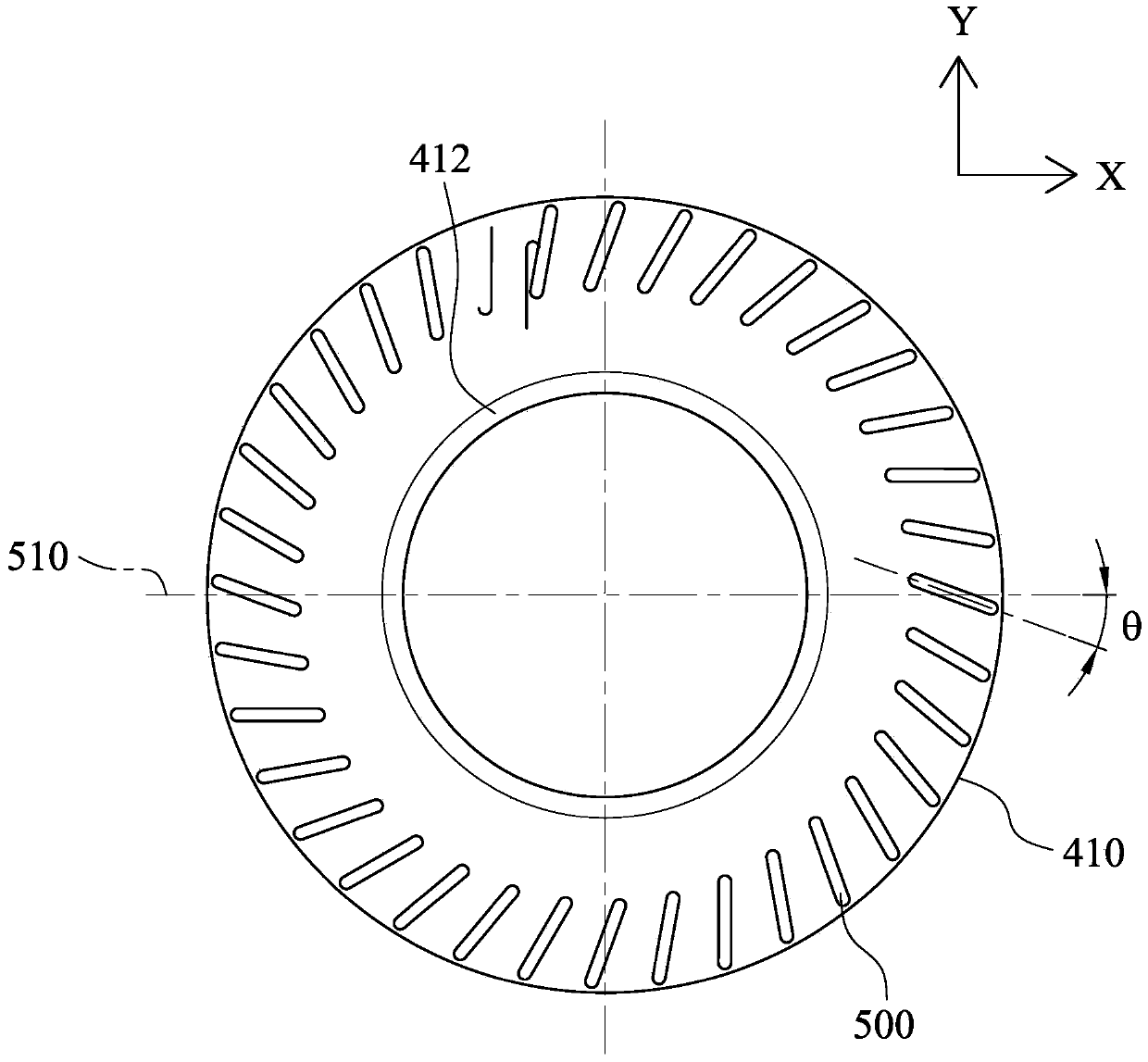

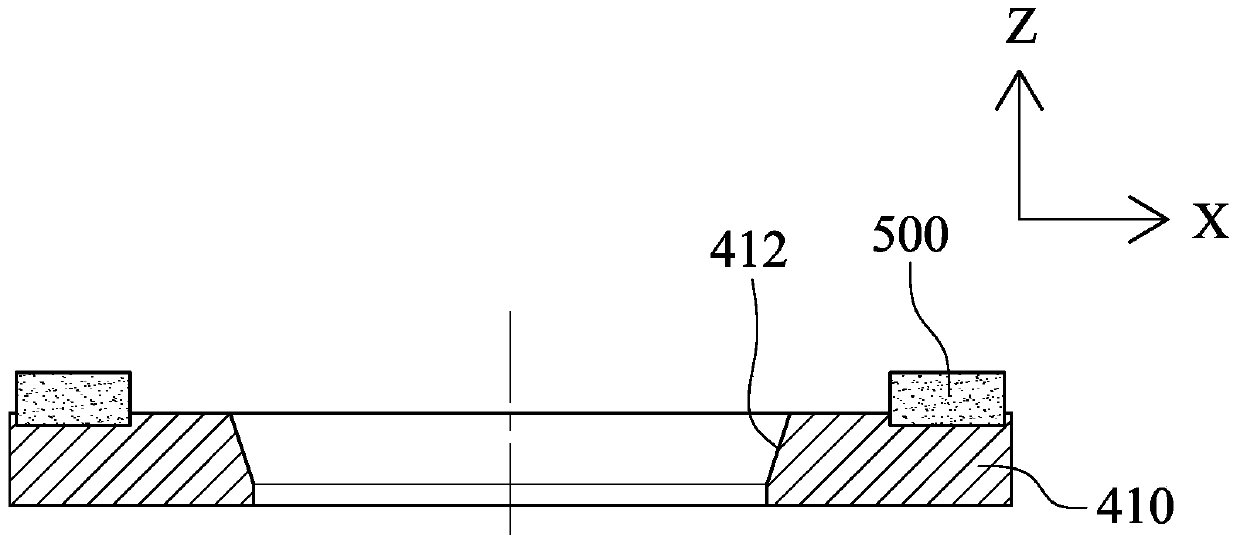

[0026] Please also refer to Figure 1 to Figure 3 , figure 1 A three-dimensional schematic diagram of a grinding device 100 according to an embodiment of the present invention is shown. Figure 2A draw figure 1 A top view of the grinding wheel disc 410. Figure 2B draw Figure 2A A cross-sectional view of the grinding wheel disc 410. image 3 draw figure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap