Grating Alignment Bonding Method

A grating and lamination technology, applied in the optical field, can solve the problems of easy glue leakage, high price, uncontrollable amount of LOCA lamination glue, etc., and achieve the effect of reducing equipment cost and improving production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Example: see Figure 3 ~ Figure 5 Be explained.

[0032] The inventive method comprises the following steps:

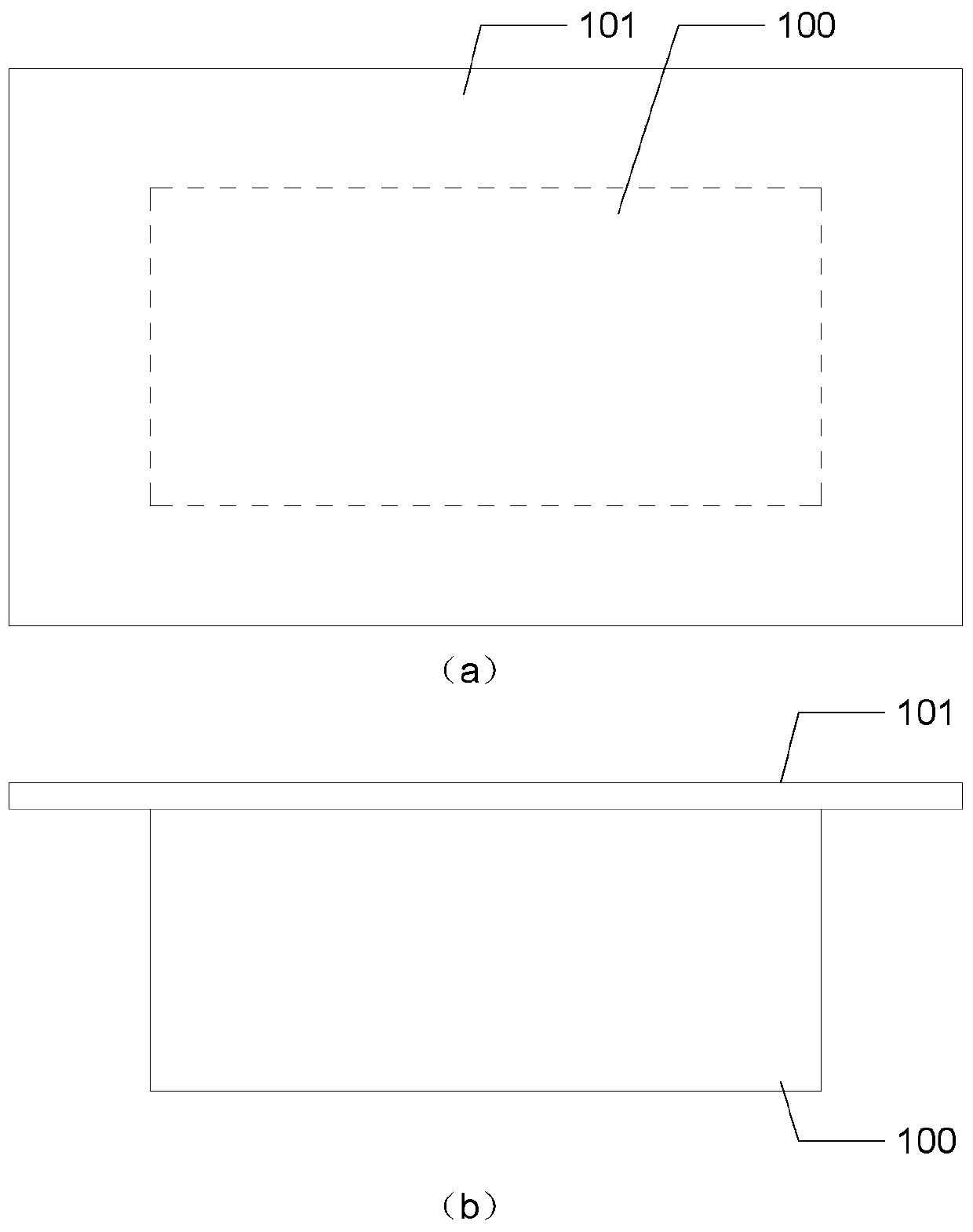

[0033] Step 1, attaching a buffer film 101 on the surface of the glass panel 100, the buffer film 101 is an optical film with a substrate solid adhesive;

[0034] The two are fixed with solid optical glue.

[0035] The area of the buffer film 101 is larger than that of the glass panel 100 , and the buffer film 101 completely covers the glass panel 100 and has an extended edge for later cutting.

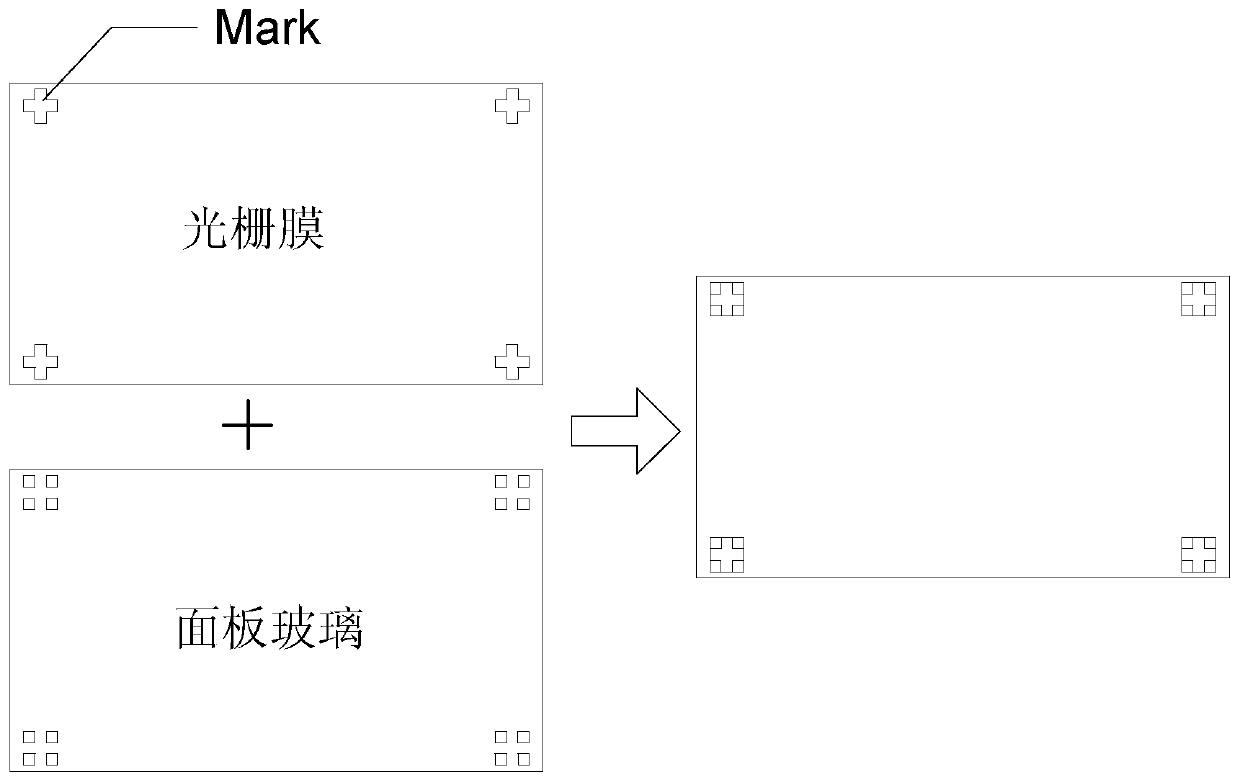

[0036] Step 2: Attach the grating film 103 on the buffer film 101 through the liquid optical glue 102, and adjust the alignment of the grating film 103 through the fluidity of the liquid optical glue and the optical alignment system to achieve high-precision lamination of the grating.

[0037] The cost of optical alignment technology is low.

[0038] The size of the grating film 103 is equivalent to that of the buffer film, that is, the area of the grating film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com