Photovoltaic glass preparation method

A photovoltaic glass and glass surface technology, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve the problems of easy failure, poor weather resistance of organic matter, etc., and achieve easy release, easy control, and small shrinkage of graphic structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

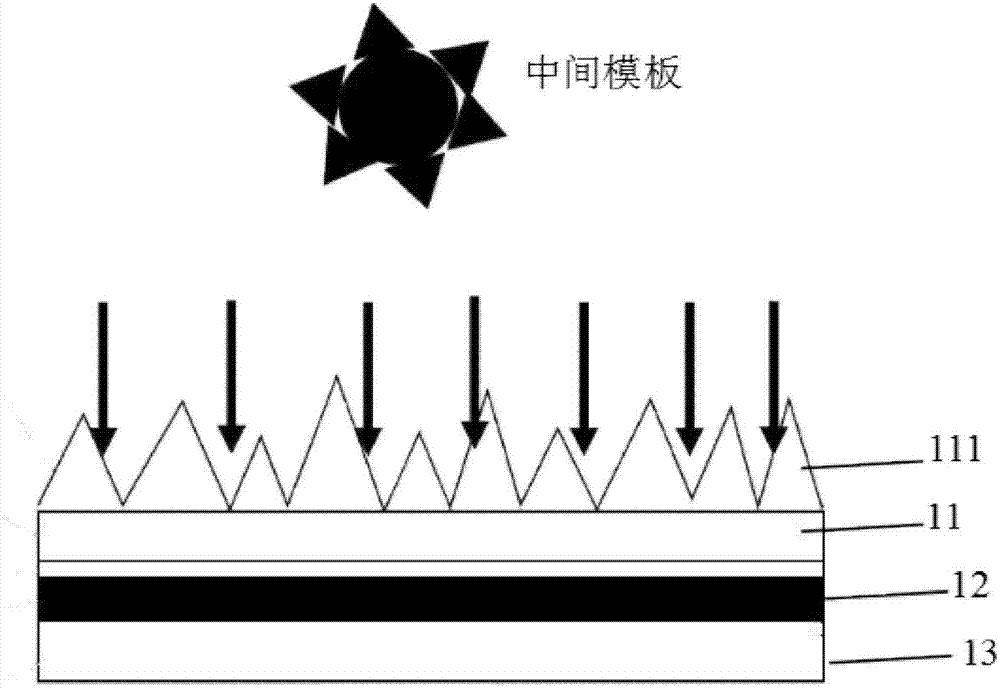

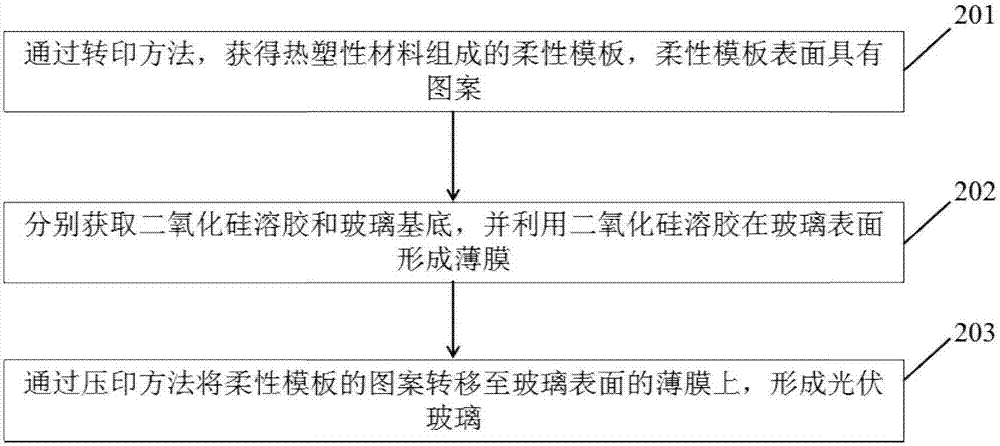

[0058] In this embodiment, the method for preparing a solar cell module includes the following steps:

[0059] A flexible template composed of thermoplastic material was obtained by the secondary transfer method. In this embodiment, polydimethylsiloxane (PDMS) is selected as the preparation material of the flexible template. Exemplarily,

[0060] First, mix dimethylsiloxane (monomer) and curing agent uniformly at a mass ratio of 8:1 to prepare a liquid PDMS mixed solution. Optionally, place the liquid PDMS mixed solution in a vacuum oven at room temperature Air bubbles in the mixed solution can be removed inside. In this embodiment, the mass of dimethylsiloxane used is 12 g, and the mass of curing agent is 1.5 g. It can be understood that the mass ratio of PDMS and curing agent can also be set to other reasonable parameters such as 10:1 or 15:1, and the mass ratio of PDMS and curing agent is not strictly limited. In this embodiment, the curing agent is selected such as YLG...

Embodiment 2

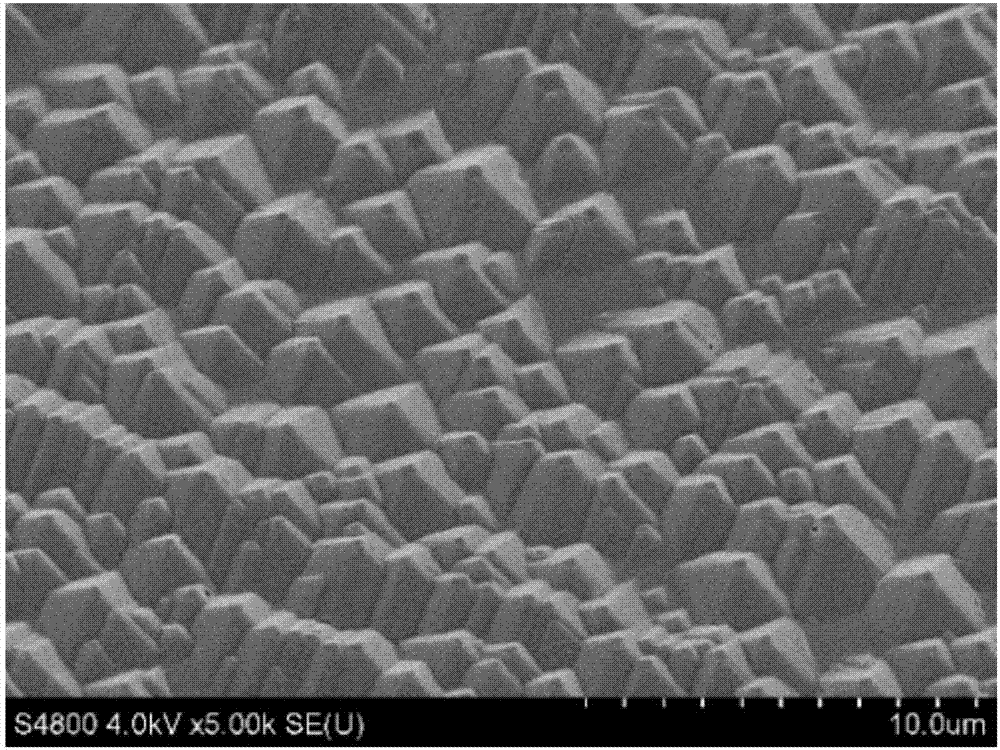

[0069] Silica sol was spin-coated on the glass substrate surface. Exemplary: at room temperature (25°C), mix dimethyldiethoxysilane (DDS), hexamethylsiloxane (HMDS), and methyltriethoxysilane (MTEOS) at a ratio of 1:1: 1 Dissolve in 40mL of mixed solvent composed of ethanol and water. In practical applications, dimethyldiethoxysilane, hexamethylsiloxane, methyltriethoxysilane, deionized water, and ethanol solvents are mixed according to the molar ratio of 1 : 1:1:10:15 mixing (the molar ratio of silicon source, deionized water, and ethanol solvent is 3:10:15), and adjust the pH of the mixed solution to 4.0 with concentrated nitric acid, stir evenly for 1 hour, and react to form acidic silica Hydrosol, the molar percentage of silicon dioxide in this acidic silica hydrosol is 10%; Acidic silica hydrosol is aged and treated subsequently for 48h; The acidic silica hydrosol and methyl benzoate Esters are evenly mixed, and the ratio of methyl benzoate is 10% of the weight ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap