Key bit groove milling device

A milling device, the technology of the key head, applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

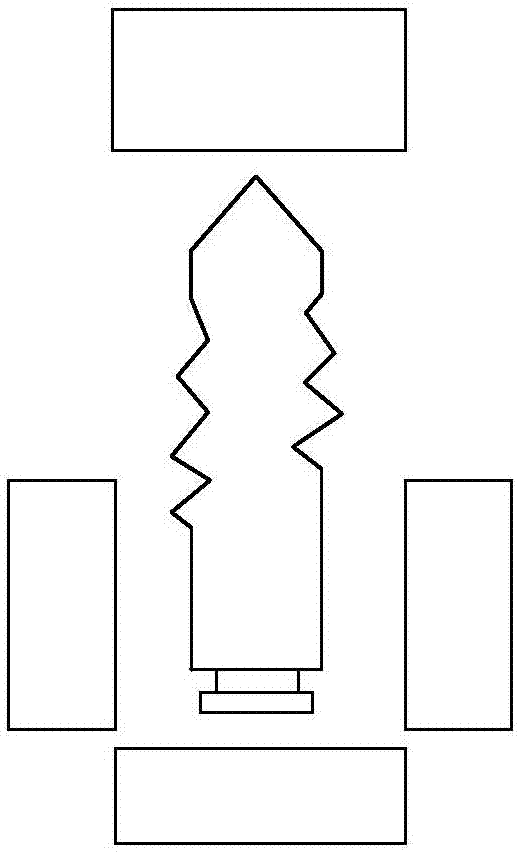

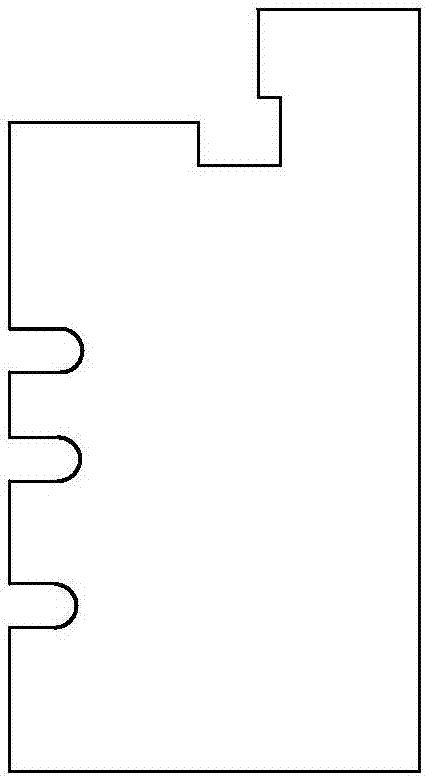

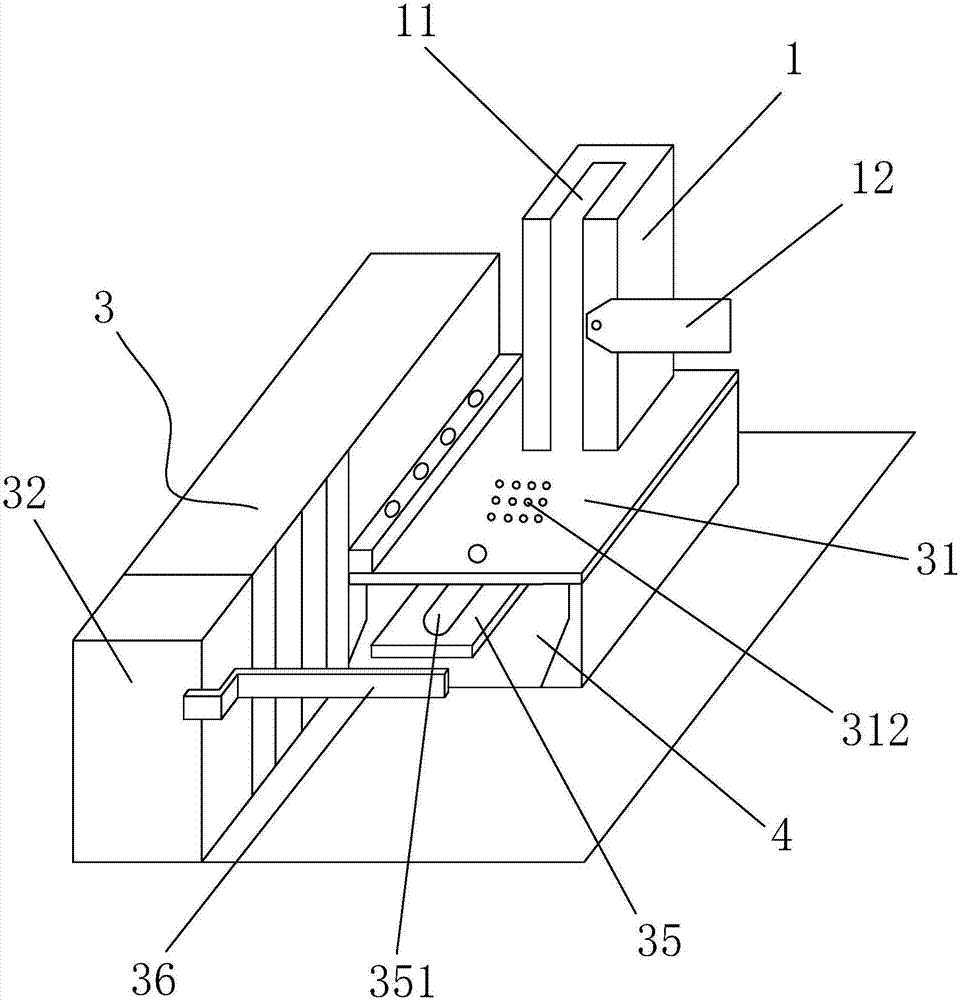

[0017] refer to Figure 3-Figure 5 , a kind of key bit milling device of the present invention, comprises the feeding frame 1 that is used for placing key bit in batches that is integrally formed, the milling cutter 2 that is used for carrying out milling processing to key bit, is used for pushing key bit to milling machine. Knife 2 carries out the pushing device 3 of slot milling processing and is used for the discharge outlet 4 that the key head that completes slot milling process is discharged, is provided with the feed slot 11 that shape matches with the key head in the feed frame 1, feed slot 11. An opening is provided at the end of the key head. The pushing device 3 includes a push plate 31 for transporting the key head and a milling cylinder 32 for driving the push plate 31 to move back and forth. On the cylinder support arm of the milling cylinder 32 A cylinder casing is provided, and the push plate 31 is provided with a circular through hole 311. The push plate 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com