A lifting feeding device

A feeding device and lifting technology, applied in the field of waste cable recycling equipment, can solve the problems of insufficient belt surface friction, falling waste circuit boards, troubles, etc., and achieve the effect of small footprint and stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

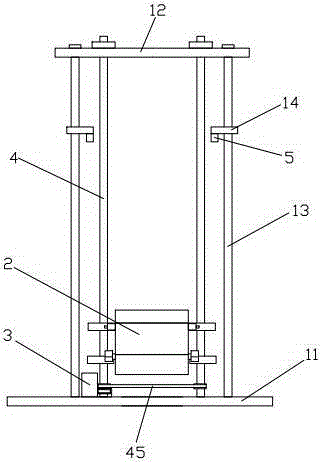

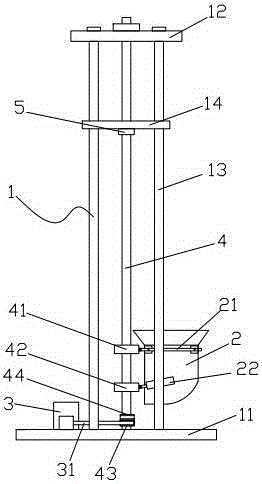

[0012] Such as figure 1 , 2 As shown, a lifting feeding device of the present invention includes a frame 1, a lifting drive mechanism, a loading bin 2 and an electric control box. Wherein, lifting driving mechanism comprises two sets of screw mandrel assemblies and the motor 3 of driving screw mandrel assembly; The upper end of the side is respectively hinged with the upper lifting block 41 of the two sets of screw assemblies through a fixed rod 21, and a cylinder 22 for driving the loading bin to turn over and unload is respectively installed on the lower parts of the two sides of the loading bin 2, and the output shaft of the cylinder 22 is connected to the The corresponding lower lifting blocks 42 on the same side are hinged. The top of frame 1 is also provided with a travel switch 5 for detecting that the loading bin is in place.

[0013] In this embodiment, the frame 1 includes a bottom plate 11 , a top plate 12 and a column 13 fixedly connected between the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com