Vacuum sample transfer device

A sample transfer and vacuum technology, which is applied to the analysis of materials and instruments, can solve the problems of high cost, poor reliability, and sample drop, and achieve the effects of improved stability, strong versatility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following embodiments will be used to further illustrate the present invention in conjunction with the accompanying drawings.

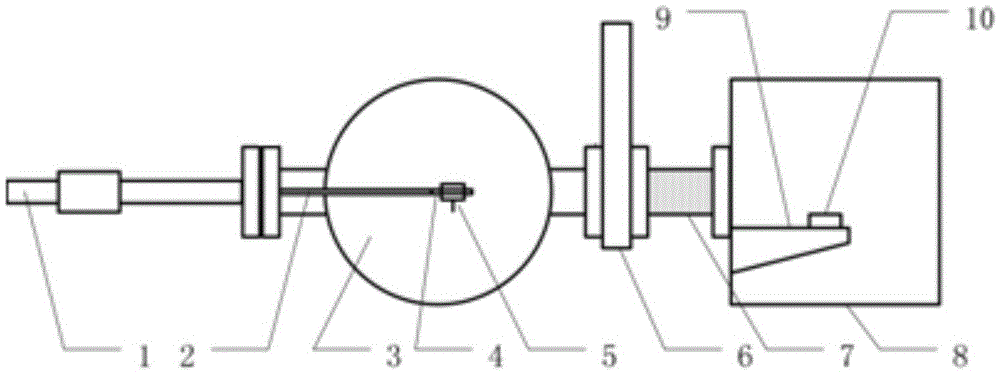

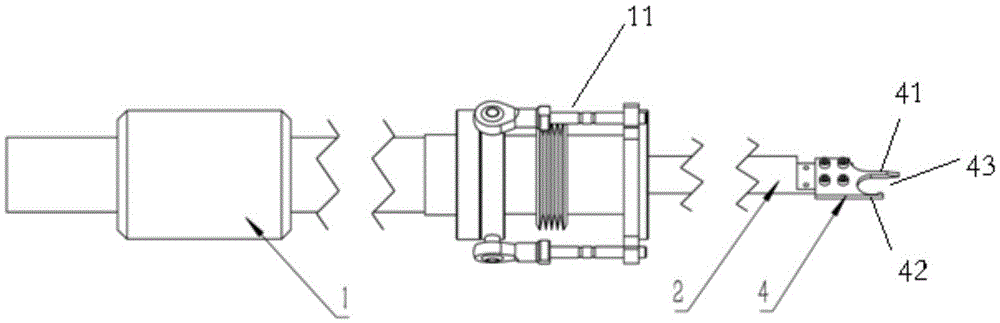

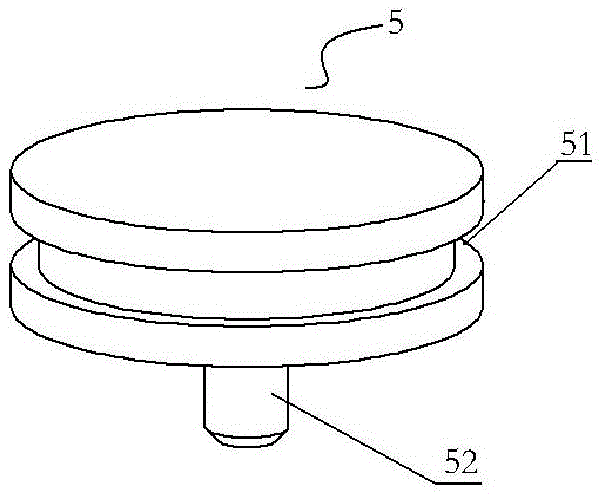

[0036] figure 1 Showing the main technical content of this specific embodiment, this specific embodiment provides a vacuum sample transfer device, which includes: a magnetic rod 1 with a vacuum outer magnetic ring and a vacuum inner magnetic ring, a vacuum chamber 3. The sample transfer rod 2, the sample cup 5 used to carry the vacuum sample, and the vacuum pipeline used to connect the vacuum chamber 3 and the sampling or sample receiving equipment; wherein, the magnetic rod drives the outer magnetic ring of the vacuum to utilize the magnetic force function, it can drive the vacuum inner magnetic ring to move in axial, radial and circumferential directions; the vacuum inner magnetic ring and the sample transfer rod 2 are arranged inside the vacuum chamber, and the The inner magnetic ring is connected, and the front end of the sample transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com