Crystal lamp shade and manufacturing method thereof

A production method and lampshade technology, applied in the field of lampshade, can solve the problems of easy falling of crystals, discount, labor and time consumption, etc., and achieve the effects of ensuring product quality, avoiding confusion, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

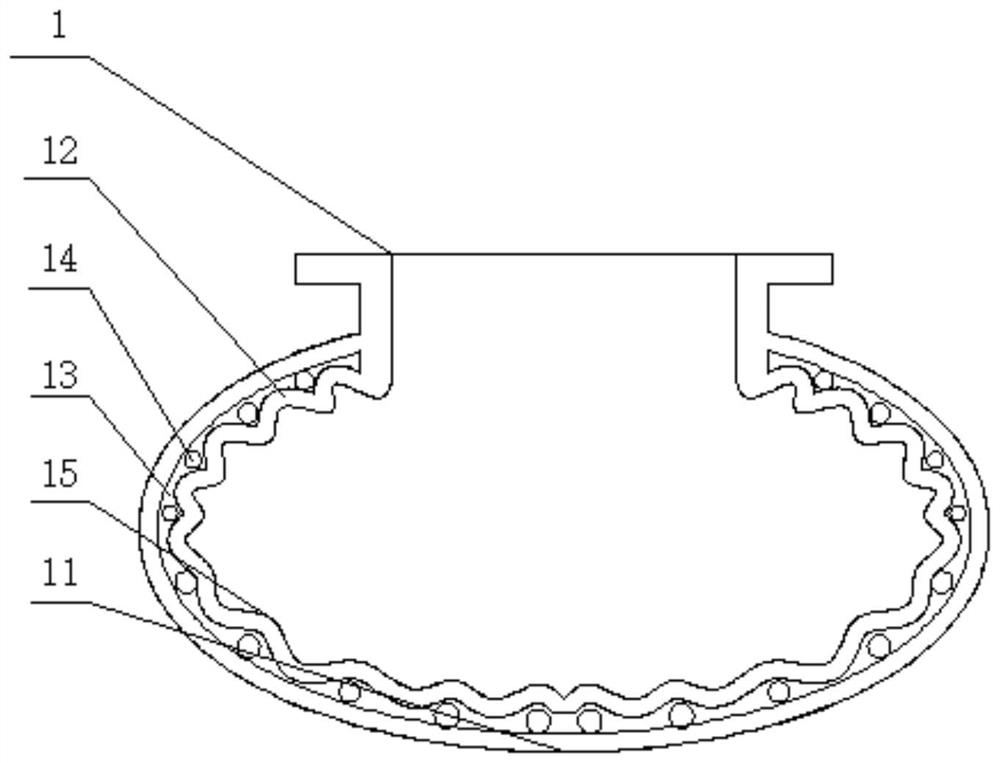

[0024] A crystal lampshade and a manufacturing method thereof, comprising a lampshade body 1, the lampshade body 1 comprising a first plastic plate 11 and a second plastic plate 12, the ends of the first plastic plate 11 and the second plastic plate 12 are both Fixedly connected, the sides of the first plastic plate 11 and the second plastic plate 12 form a positioning cavity 13, and the sides of the positioning cavity 13 are fixedly inlaid with crystal beads 14, through the first plastic plate 11 and the second plastic plate 12 forms a positioning cavity 13, which can position and wrap the crystal beads 14, which can not only ensure structural stability and avoid falling, but also facilitate light-transmitting use and ensure aesthetics and decorative effects. The second plastic plate 12 Wrinkles 15 are formed on the surface, and the side surfaces of the folds 15 are fixedly wrapped on the surface of the crystal beads 14, and the folds 15 are formed by compression to separate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com