Sheet feed device and image forming apparatus including the same

A technology for supplying a device and a sheet material, which is applied in the directions of image communication, transportation and packaging, electric recording process applying charge patterns, etc., can solve problems such as poor operability of sheet material replenishment operation, etc., and achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

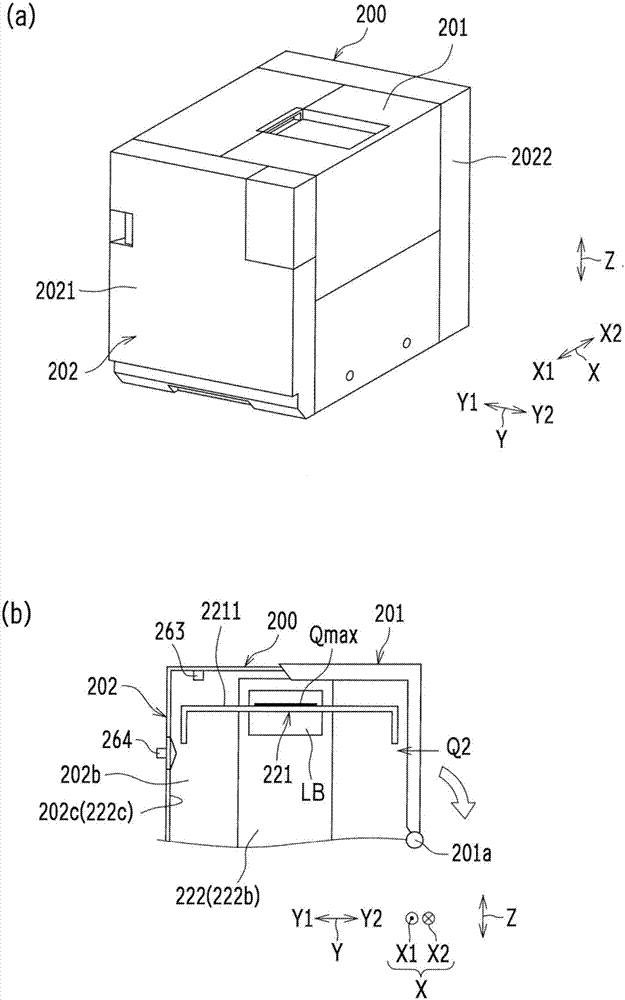

[0091] Figure 6 It is a plan view showing the inner surfaces of the access cover 201 and the side cover 203 according to the first embodiment of the present invention. Fixing screw holes 301 a to 301 c and 302 a to 302 c for fixing the opening and closing cover side stopper 222 d are provided on the inner surface of the opening and closing cover 201 . In addition, locking portions 303a and 303b for fixing the side cover side stopper 222e are provided on the inner surface of the side cover 203 .

[0092] exist Figure 6 In the example shown, the screw holes 301a and 301c for fixing are provided at the same position in the depth direction X and at different positions in the vertical direction Z, and the screw holes 302a and 302c for fixing are provided so as to correspond to the screw holes for fixing respectively. 301a and 301c are located at the same position in the up-down direction Z but are located at different positions in the depth direction X. The fixing screw hole 3...

no. 2 approach

[0102] Next, use Figure 11 , Figure 12 A case where the sheet size of the sheet P loaded on the loading tray 221 is changed to the B5 size will be described. Figure 11 It is a perspective view showing a state where the cover 201 is opened with the cover side stopper 222d and the side cover side stopper 222e attached to the sheet size position of B5. Figure 12 It is a perspective view showing a state where the cover 201 is closed with the cover side stopper 222d and the side cover side stopper 222e attached to the sheet size position of B5.

[0103] When the size of the sheet P loaded on the loading tray 221 is B5, the screw holes 312a, 312c, and 312d of the opening and closing lid side stopper 222d are aligned with the Figure 6 The shown fixing screw holes 302a-302c are aligned and threaded. And the locking piece 322a of the side cover side stopper 222e is fitted into the Figure 6 The locking portion 303b shown positions the positioning protrusion 324 and the screw h...

no. 3 approach

[0108] Next, use Figure 13 , Figure 14 A case where the sheet size of the sheet P loaded on the loading tray 221 is changed to a letter size will be described. Figure 13 It is a perspective view showing a state where the cover 201 is opened with the cover side stopper 222d and the side cover side stopper 222e attached to a letter-sized sheet size position. Figure 14 It is a perspective view showing a state where the cover 201 is closed after the cover-side stopper 222d and the side cover-side stopper 222e are attached to letter-sized sheet size positions.

[0109] When the size of the sheet P loaded on the loading tray 221 is a letter size, the first mounting surface 311b of the opening and closing cover side stopper 222d faces the inner surface of the opening and closing cover 201, and the screw hole 313 is aligned with the inner surface of the opening and closing cover 201. Figure 6 The shown fixing screw holes 302b are aligned and threaded. On the second limiting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com