Device for improving coiling folding mark of stainless steel cold annealing and pickling line and use method of device

A pickling line and stainless steel technology, which is applied in the field of stainless steel cold rolling, can solve the problems of poor control, fluctuation of product mechanical properties, and narrow position of the exit area of the continuous production line, so as to reduce the dependence on manual operation, avoid production line slowdown, and improve The effect of padding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better illustrate the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred examples, and the scope of protection of the present invention is not limited to the examples given.

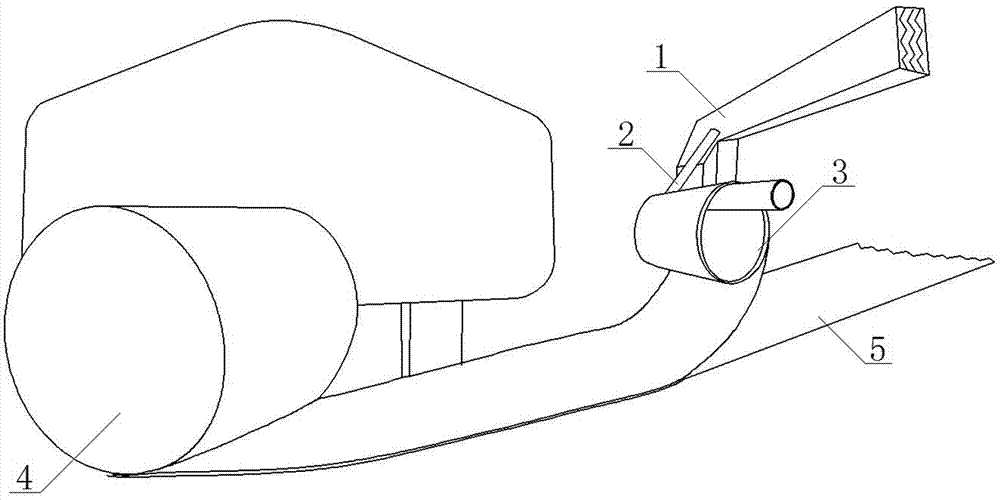

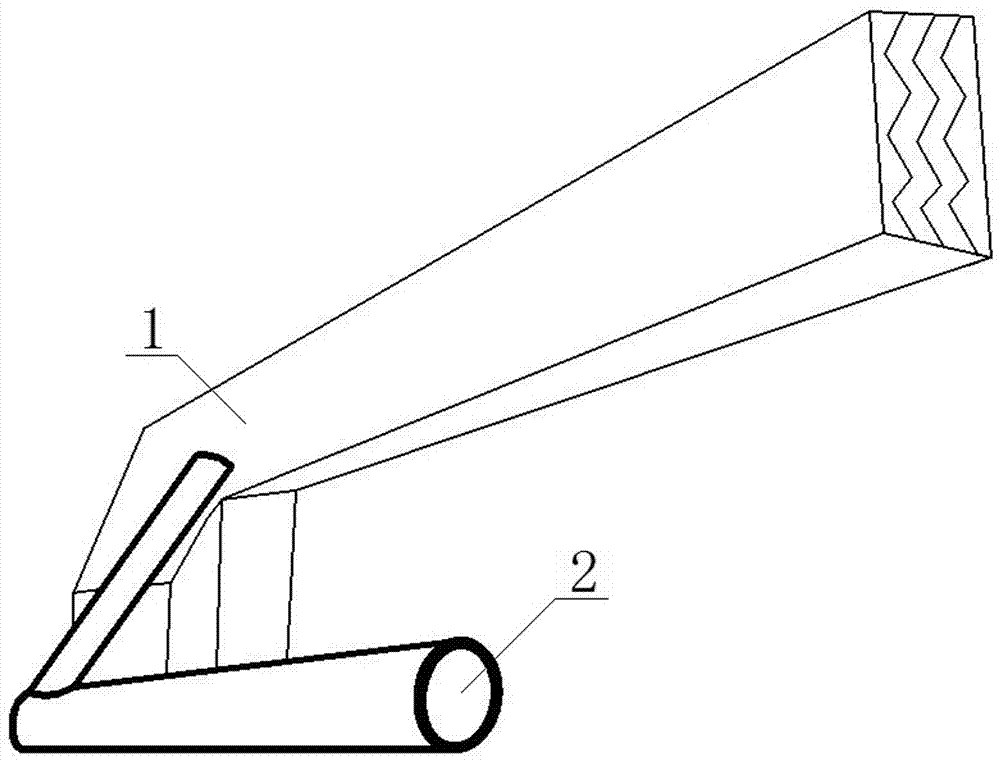

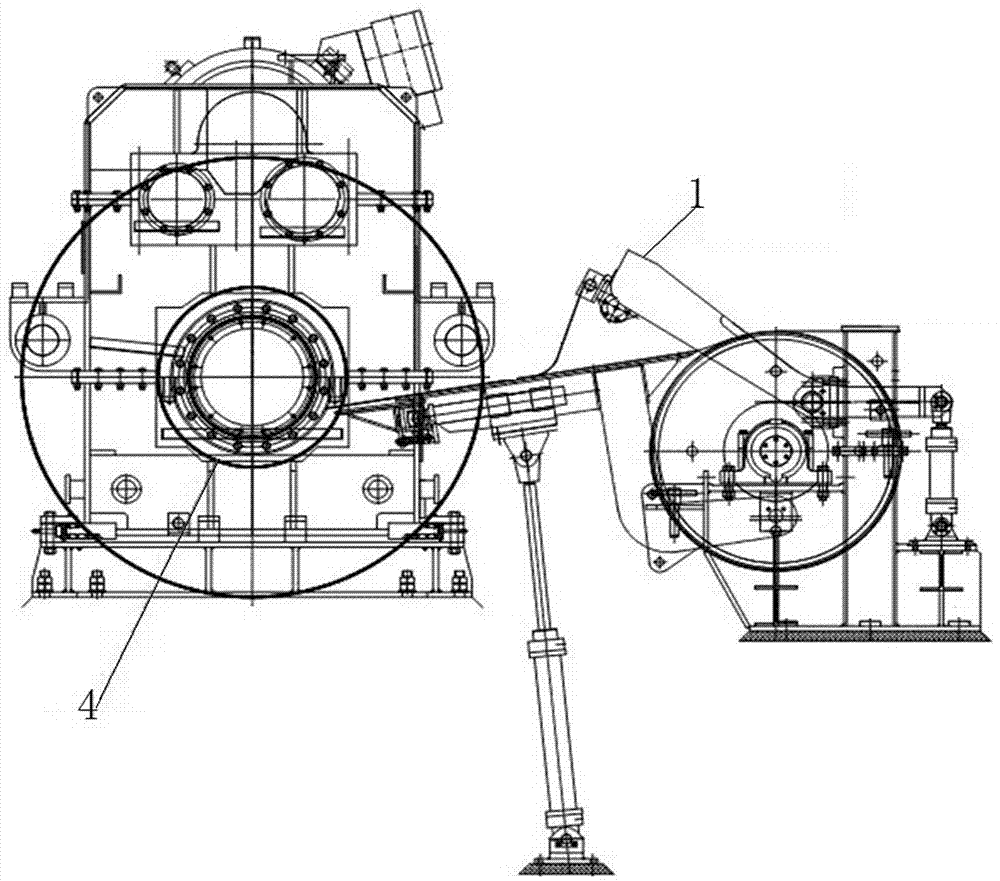

[0016] A device for improving the coiling crease of stainless steel cold annealing pickling line. An auxiliary bracket 2 is welded on the outlet pinch roller bracket 1 in the exit area. The auxiliary bracket 2 is in the shape of "L", and one end is connected and fixed on the outlet pinch roller On the support 1, the other end is a free end, and the corrugated paper roll 3 is sleeved on the crossbar where the auxiliary support 2 free ends are located, and the axial direction of the corrugated paper roll 3 is parallel to the axial direction of the coiler drum 4.

[0017] When using this device, the corrugated paper roll 3 is set on the auxiliary support 2, and when the corrugated paper is used, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com