Powder release device and washing machine

A feeding device and powder technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of affecting the feeding accuracy, powder agglomeration, powder falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

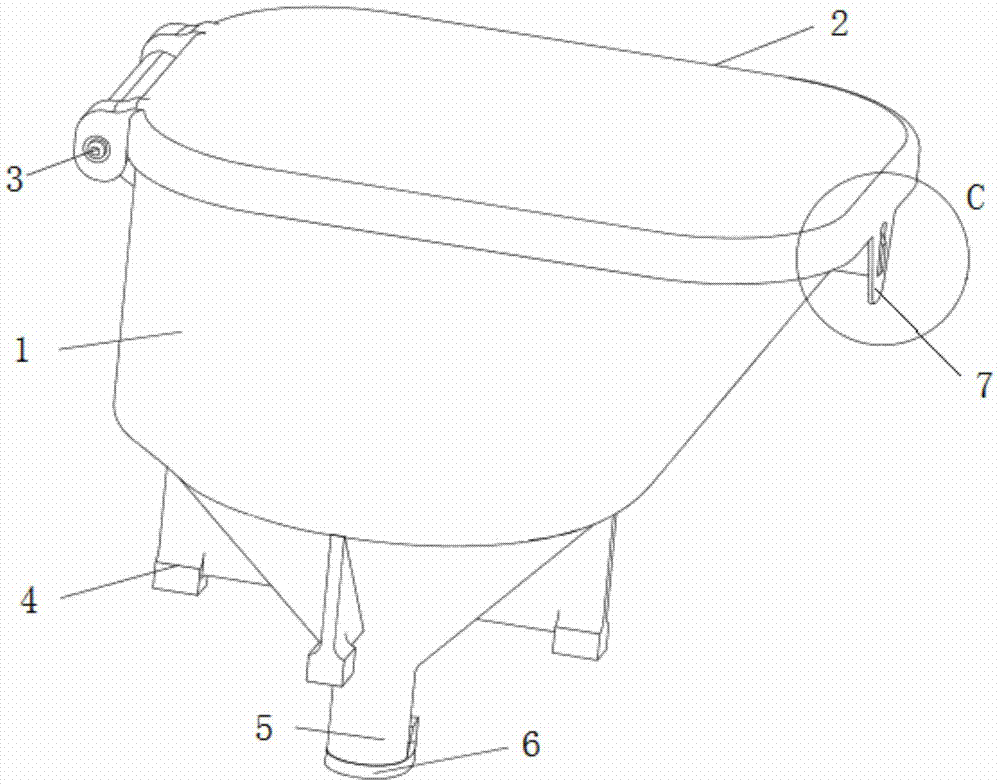

[0026] Such as figure 1 As shown, a powder dispensing device of the present invention includes a dispensing container 1, an openable sealing cover 2 is provided at the top feeding port of the dispensing container 1 to close the feeding port, and a dispensing port 5 at the bottom of the dispensing container 1 is provided with The opening and closing sealing member 6 seals the insertion port 5 , and a feeding device is arranged in the insertion container 1 to quantitatively send the powder in the insertion container 1 from the insertion opening 5 at the bottom.

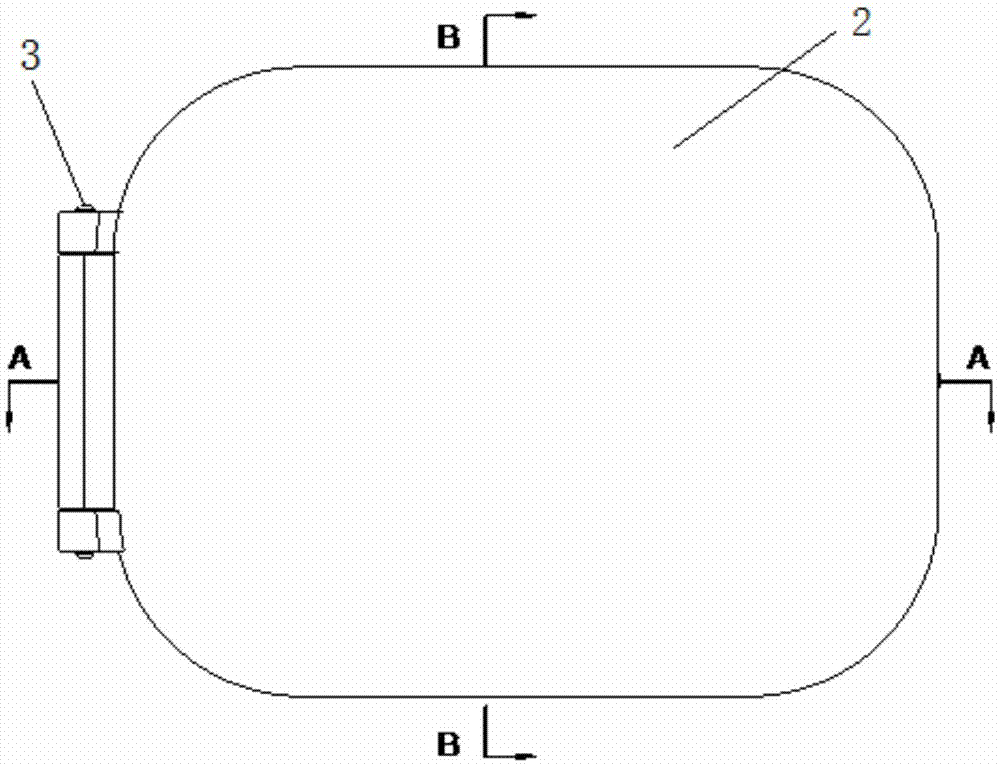

[0027] An openable and closable sealing cover 2 is rotatably connected with the delivery container 1 through a rotating shaft 3 at the feed inlet on the top of the delivery container 1 .

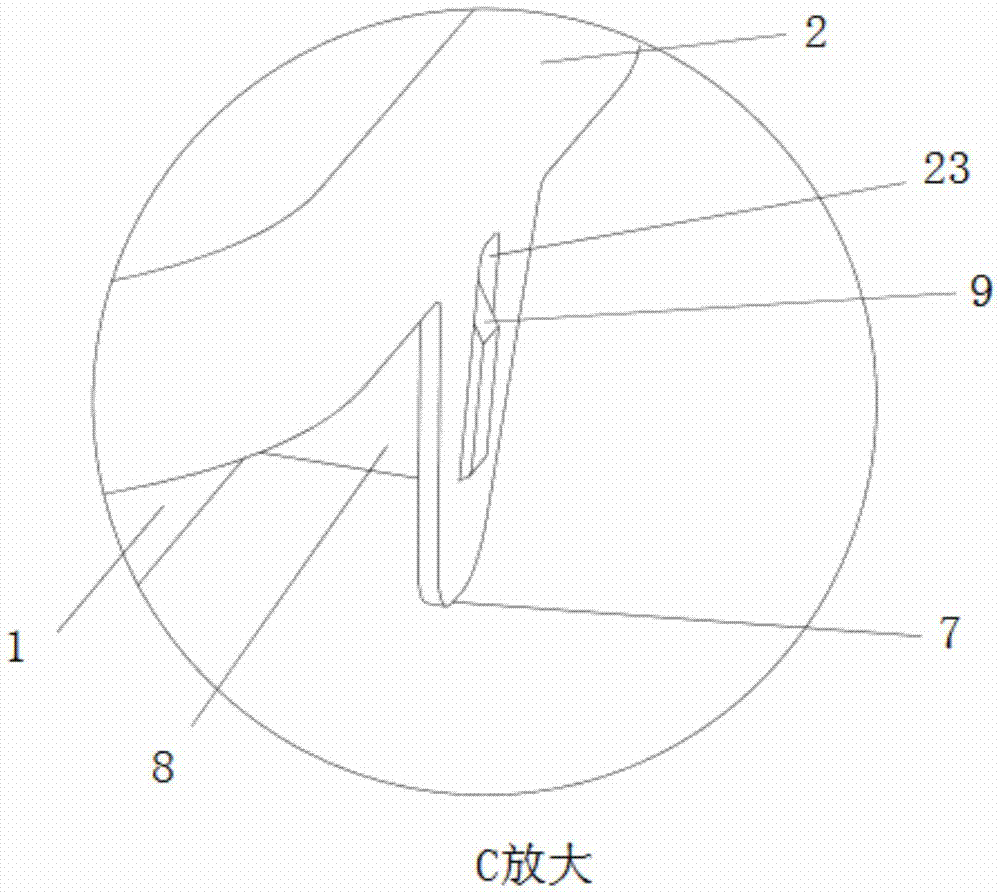

[0028] Such as figure 1 , 2 As shown, on the delivery container 1 and the sealing cover 2, there are also buckles 7 and protrusions 8 that cooperate with each other to lock the delivery container 1 and the sealing cover 2.

[0029]...

Embodiment 2

[0040] This embodiment is a washing machine equipped with the powder injecting device described in Embodiment 1.

[0041] The invention relates to a washing machine. A powder feeding device is installed on the washing machine, including a feeding container. An openable sealing cover is arranged at the feeding port on the top of the feeding container to seal the feeding port, and an openable sealing cover is arranged at the feeding port at the bottom of the feeding container. The combined sealing member seals the delivery port, and a feeding device is arranged in the delivery container to quantitatively send the powder in the delivery container from the bottom delivery opening. Since the sealing cover is provided to close the feeding port and the sealing member is used to close the feeding port, the powder in the feeding container is not easy to absorb moisture and agglomerate or lose efficacy, and prevents wrong feeding, improving the feeding accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com