Engine, engine variable compression ratio mechanism and control method thereof

A compression ratio, engine technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of high fuel consumption and emissions, and achieve the effect of prolonging service life and reducing sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The compression ratio of the engine refers to the degree to which the engine mixture is compressed. Specifically, it can be expressed by the ratio of the total volume of the cylinder before compression to the volume of the cylinder after compression. Since the volume of the combustion chamber and the working volume of the cylinder are usually defined in advance in the design, they are all fixed parameters, so the compression ratio of the existing automobile engine cannot be changed during the working process. However, this fixed compression ratio cannot make the engine perform better in various working conditions, so there are problems of high fuel consumption and emissions.

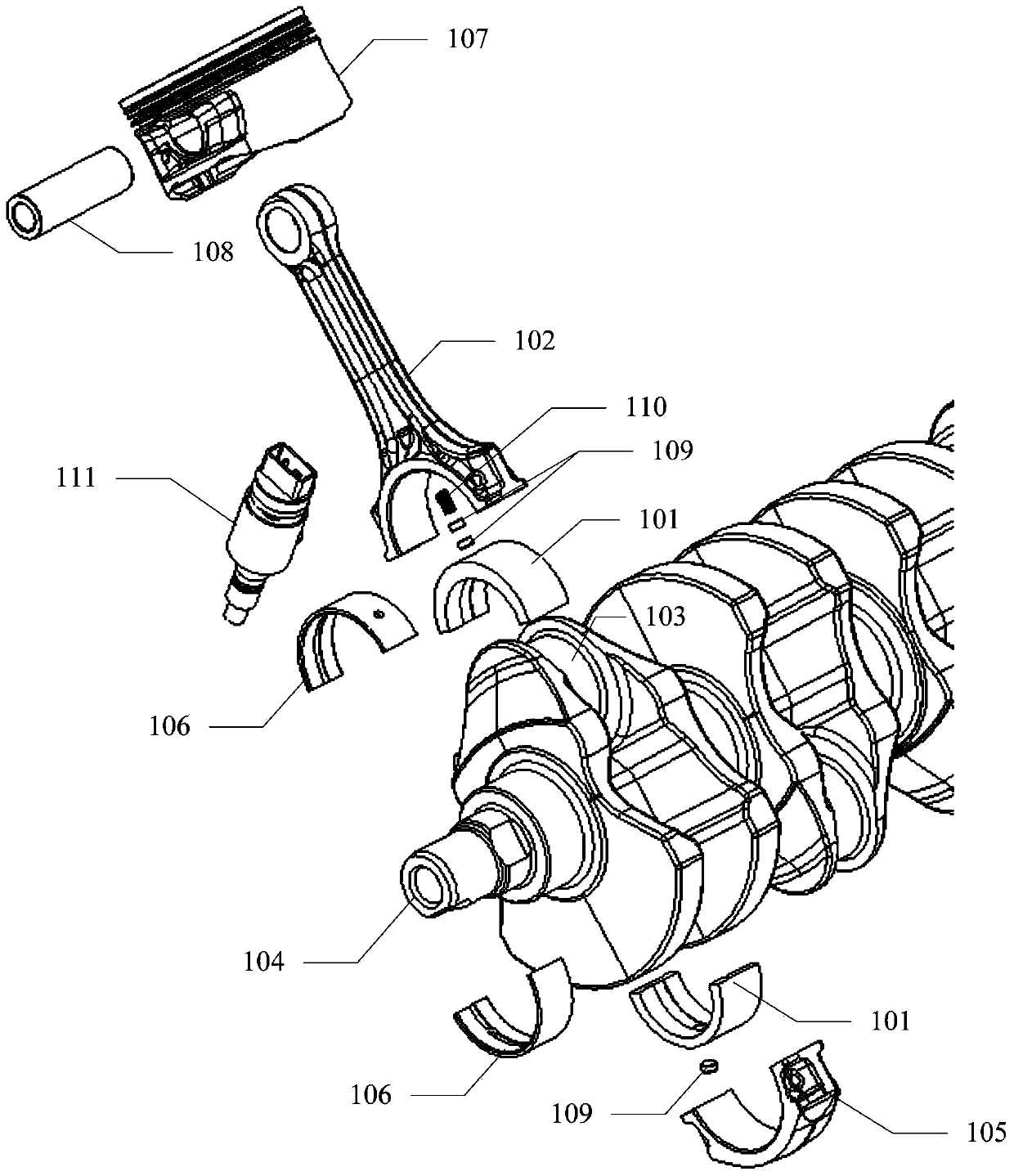

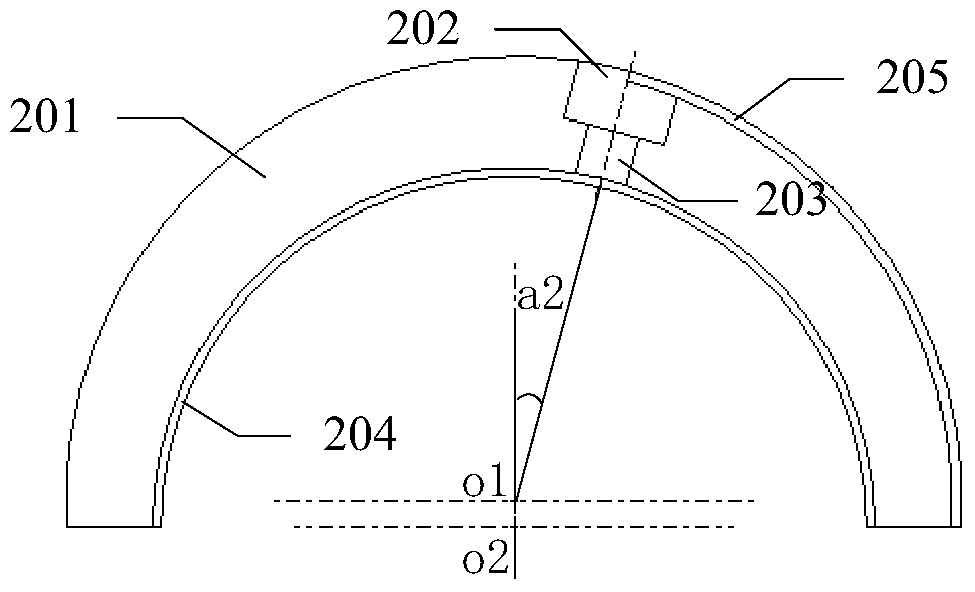

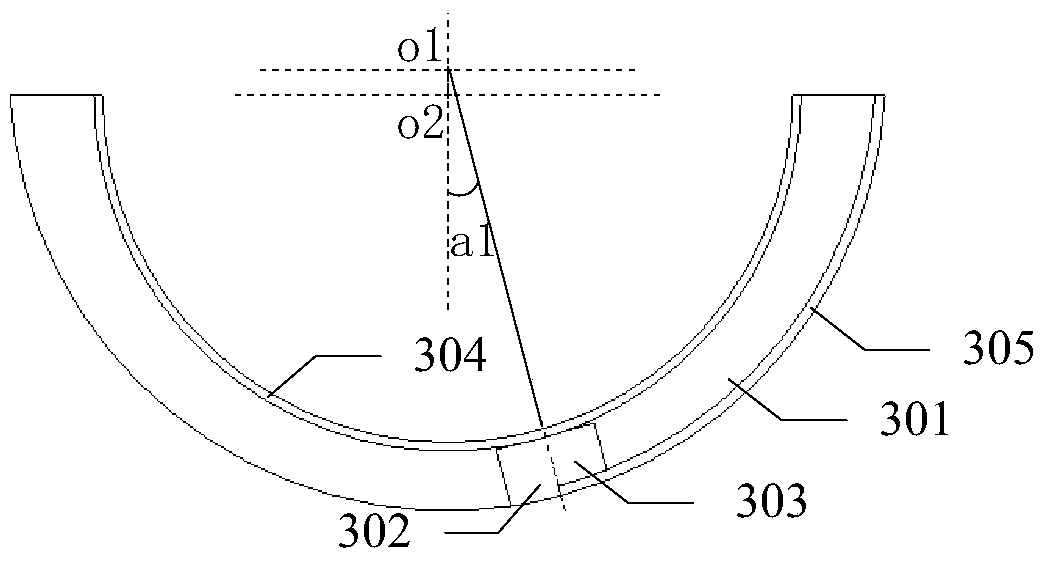

[0049] In the embodiment of the present invention, the eccentric bearing bush is assembled between the connecting rod and the crank journal of the crankshaft, and the connection and unlocking of the eccentric bearing bush and the big end hole of the connecting rod is controlled by hydraulic pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com