Cross lapper with cotton pressing function

A net-laying machine and net-laying technology, which is applied in the direction of roll-forming mechanism, textile and papermaking, fiber processing, etc., can solve the problems of delaying the efficiency of the net-laying machine, affecting the speed of net-laying, and not being seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

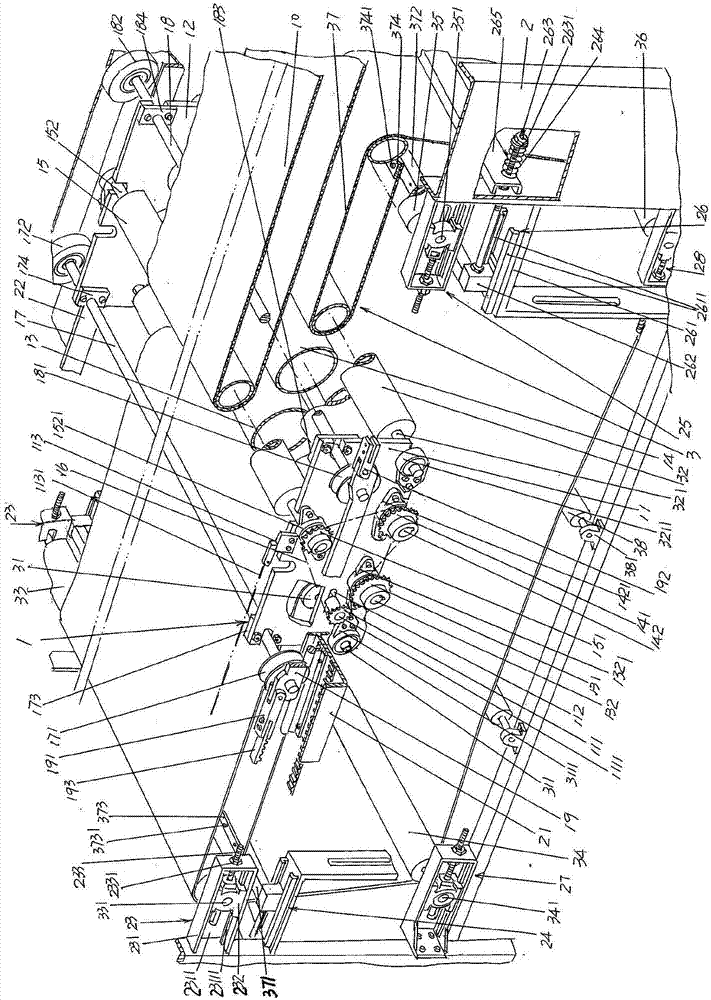

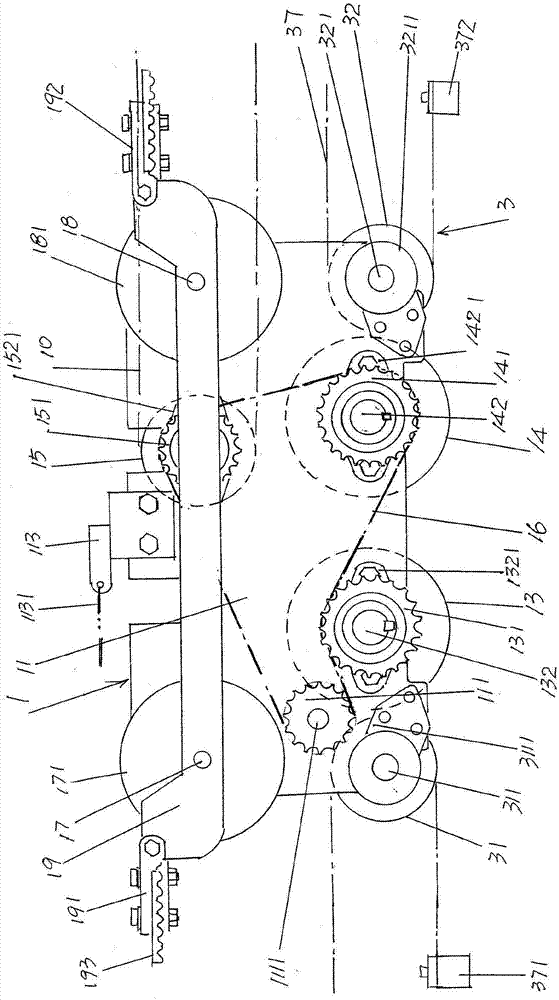

[0024] See figure 1 , shows a net-laying trolley assembly 1 of the structural system of the net-laying trolley with the function of pressing cotton, and this net-laying trolley assembly 1 comprises a net-laying trolley front wall panel 11, and this net-laying trolley front wall panel 11 and The front beam 21 of the frame of the frame 2 of the net-laying machine forms a rolling pair; a shape and size are the same as the net-laying trolley rear wallboard 12 of the net-laying trolley front wallboard 11, and this net-laying trolley rear wallboard 12 is identical to the aforementioned The front wallboard 11 of the net-laying trolley is corresponding and forms a rolling pair with the frame rear crossbeam 22 of the frame 2; a left net-laying roller 13 and a right net-laying roller 14, and the left and right net-layping rollers 13, 14 are connected with each other The left and right corresponding states are rotatably supported between the front and rear wallboards 11,12 of the aforeme...

Embodiment 2

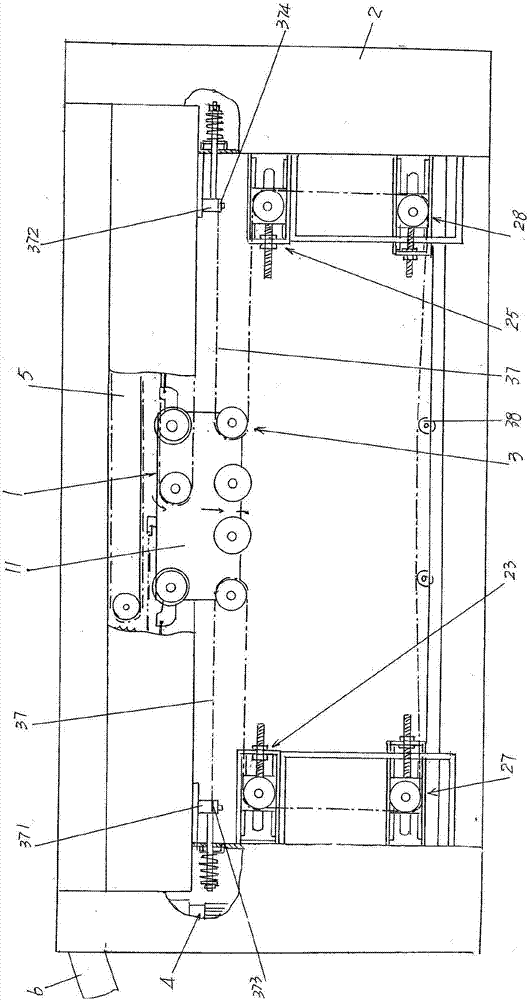

[0050] See image 3 , with respect to embodiment 1, the present embodiment 2 fixes the left end bottom of the cotton pressing curtain 37 of the cotton pressing curtain 37 of the structural system of the cotton pressing mechanism 3 and the left end bottom of the front and rear cross beams 21,22 of the frame. The left fixed cross bar 371 of the pressed cotton curtain is fixed between the front and rear cross beams 21, 22 bottoms of the frame at a position corresponding to the left end of the frame 2. , the bottom of the right end of the rear crossbeam 21,22 is fixed, that is, the right fixed crossbar 372 of the cotton pressing curtain is fixed between the front and rear crossbeams 21,22 bottoms of the frame at a position corresponding to the right end of the frame 2, and the cotton pressing The left end of the curtain 37 is clamped between the left bead 373 of the cotton curtain and the left fixed cross bar 371 of the curtain by pressing the cotton curtain left bead 373, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com