Sewing machine with automatic edge-alignment mechanism

A technology of sewing machine and driving mechanism, which is applied in the direction of sewing machine components, cloth feeding mechanism, sewing equipment, etc. It can solve the problems that the cloth cannot be adjusted to the position of the machine needle, the cloth cannot be operated on the opposite side, and the degree of automation is not high enough to achieve a high degree of automation. , fast sewing speed and ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

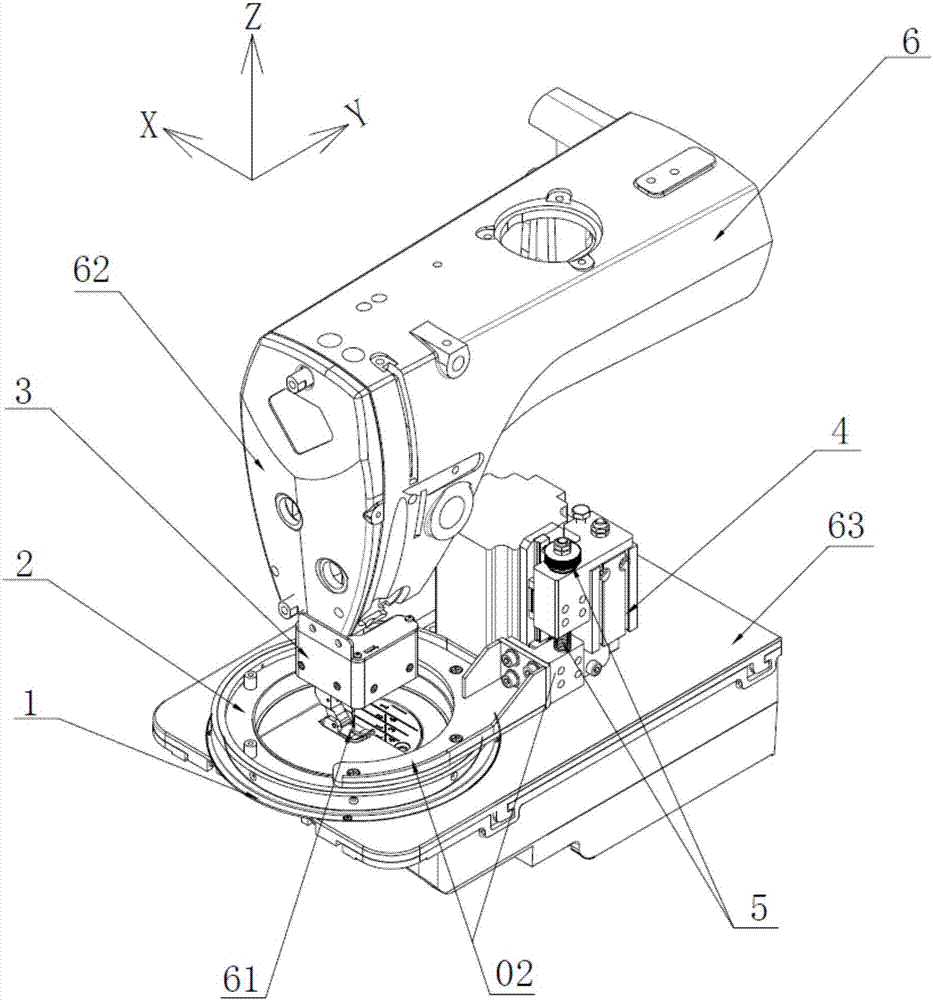

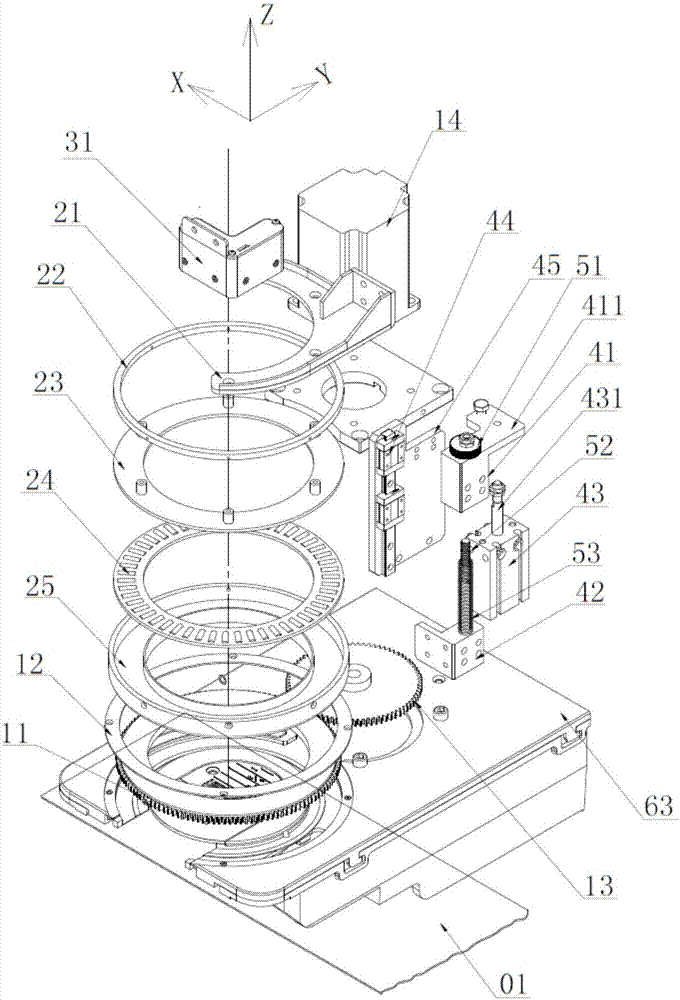

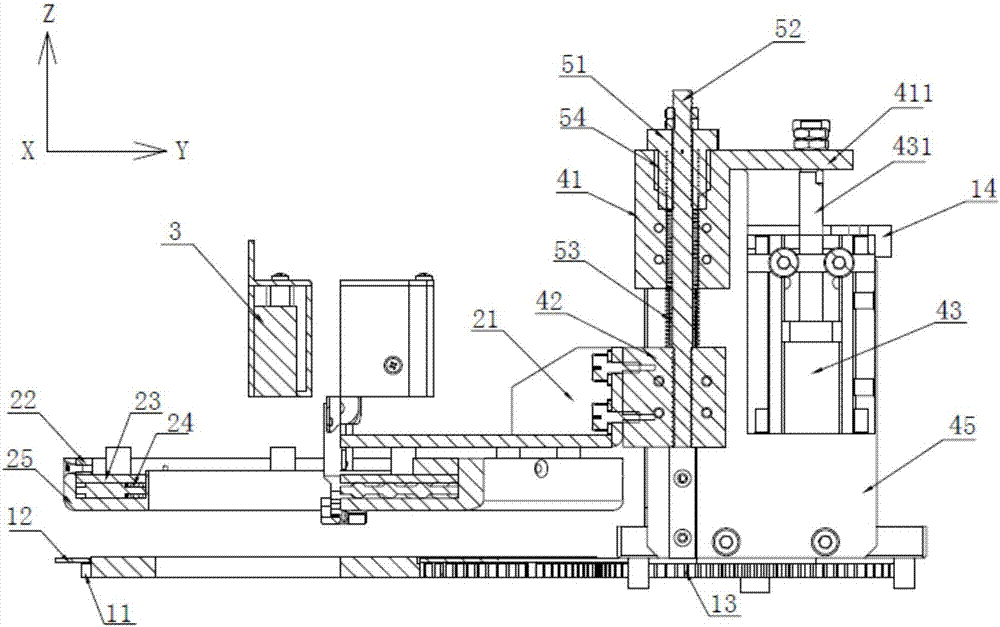

[0026] Embodiment 1, as Figures 1 to 3 As shown, let the conveying direction of the cloth 01 be the X direction, the deflection direction of the cloth 01 is the Y direction, and the vertical direction be the Z direction; a sewing machine with an automatic edge alignment mechanism in this embodiment includes a sewing machine main body 6 and an automatic alignment mechanism. The edge mechanism, the sewing machine main body 6 includes a machine head 62, a machine needle 61 located under the machine head and a base plate 63; the automatic edge alignment mechanism is located on the base plate 63, and the automatic edge alignment mechanism includes a deviation adjustment mechanism 1, a pressing mechanism 02 and a detection control mechanism. Mechanism 3; deflection adjustment mechanism 2, used to adjust the deviation of the fabric 01 in the y direction, including a passive rotating gear 11 that surrounds the machine needle 61 and can rotate around the machine needle 61, and follows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com