Preparation method and device of composite material containing high-entropy alloy coating

A high-entropy alloy and composite material technology, which is applied in the field of composite material preparation, can solve the problems of complex preparation process, high equipment requirements, and difficulty in coating, and achieves the effects of simple steps, reduced production costs, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A composite material containing a high-entropy alloy coating, comprising a substrate and a high-entropy alloy coating, wherein the high-entropy alloy coating is coated on the surface of the substrate in one step by aluminothermic reaction, and its preparation method includes the following steps:

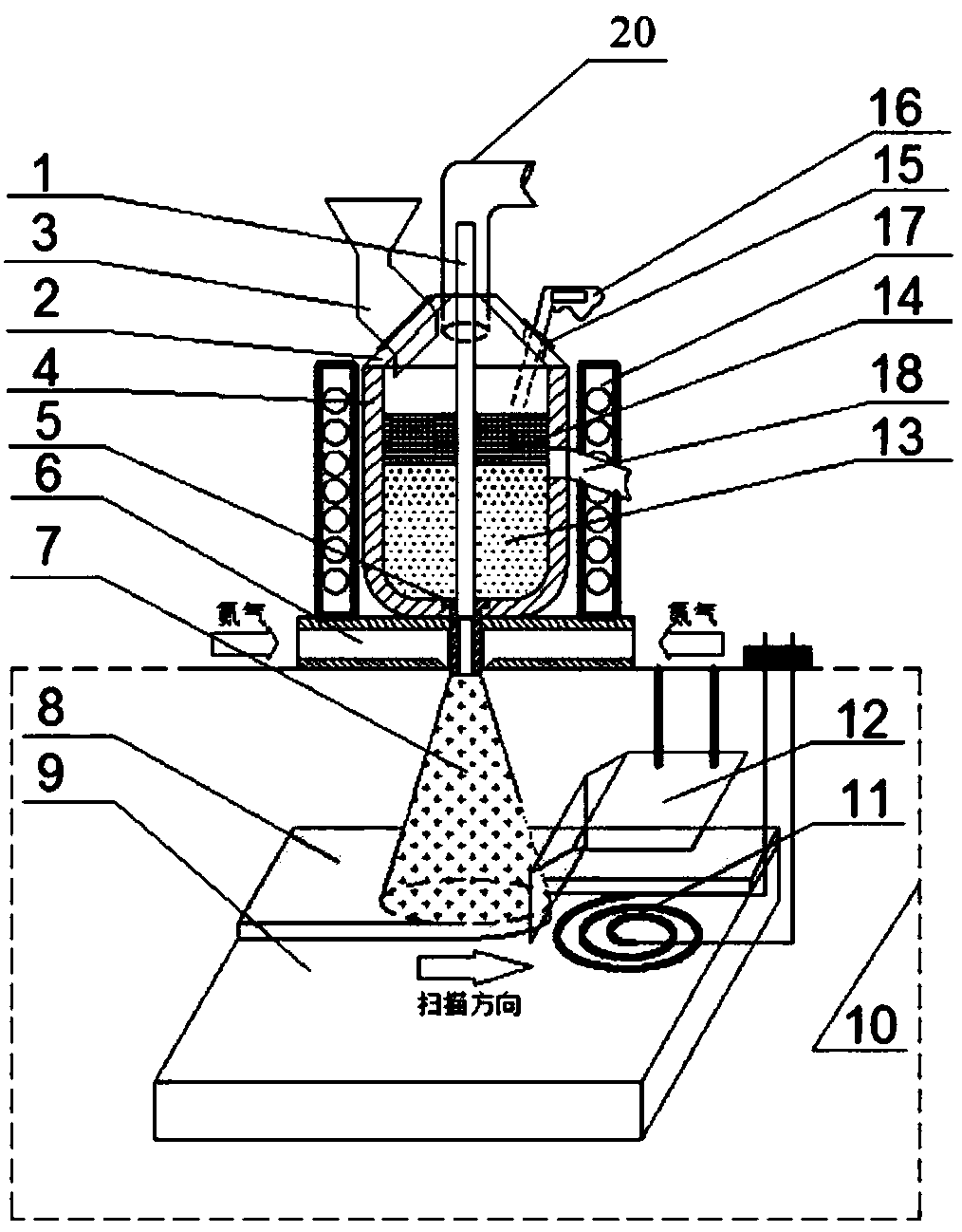

[0037] (1) Prepare the experimental device: prepare as figure 1 The shown device includes a thermite reactor 4, a rod stopper 1, a catheter 5 and an atomizer 6; the inner diameter of the thermite reactor 4 is 12mm, and a protective cover 2 is provided on the upper part, and a dust removal device is provided on the protective cover 2. 20, the plug 1 is inserted into the groove above the catheter 5, the inner diameter of the lower end of the catheter 5 (ie, the diameter of the liquid flow) is 5 mm, the preheating device 17 is placed around the thermite reactor 4, and the slag discharge pipe 18 passes through The preheating device is specially designed with holes and fixed, and t...

Embodiment 2

[0049] A composite material containing a high-entropy alloy coating, comprising a substrate and a high-entropy alloy coating, wherein the high-entropy alloy coating is coated on the surface of the substrate in one step by aluminothermic reaction, and its preparation method includes the following steps:

[0050] (1) Prepare the experimental device: prepare as figure 1 The shown device includes a thermite reactor 4, a rod stopper 1, a catheter 5 and an atomizer 6; the inner diameter of the thermite reactor 4 is 12mm, and a protective cover 2 is provided on the upper part, and a dust removal device is provided on the protective cover 2. 20, the plug 1 is inserted into the groove above the catheter 5, the inner diameter of the lower end of the catheter 5 (ie, the diameter of the liquid flow) is 5 mm, the preheating device 17 is placed around the thermite reactor 4, and the slag discharge pipe 18 passes through The preheating device is specially designed with holes and fixed, and t...

Embodiment 3

[0063] A composite material containing a high-entropy alloy coating, comprising a substrate and a high-entropy alloy coating, wherein the high-entropy alloy coating is coated on the surface of the substrate in one step by aluminothermic reaction, and its preparation method includes the following steps:

[0064] (1) Prepare the experimental device: prepare as figure 1 The shown device includes a thermite reactor 4, a rod stopper 1, a catheter 5 and an atomizer 6; the inner diameter of the thermite reactor 4 is 12mm, and a protective cover 2 is provided on the upper part, and a dust removal device is provided on the protective cover 2. 20, the plug 1 is inserted into the groove above the catheter 5, the inner diameter of the lower end of the catheter 5 (ie, the diameter of the liquid flow) is 5 mm, the preheating device 17 is placed around the thermite reactor 4, and the slag discharge pipe 18 passes through The preheating device is specially designed with holes and fixed, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com