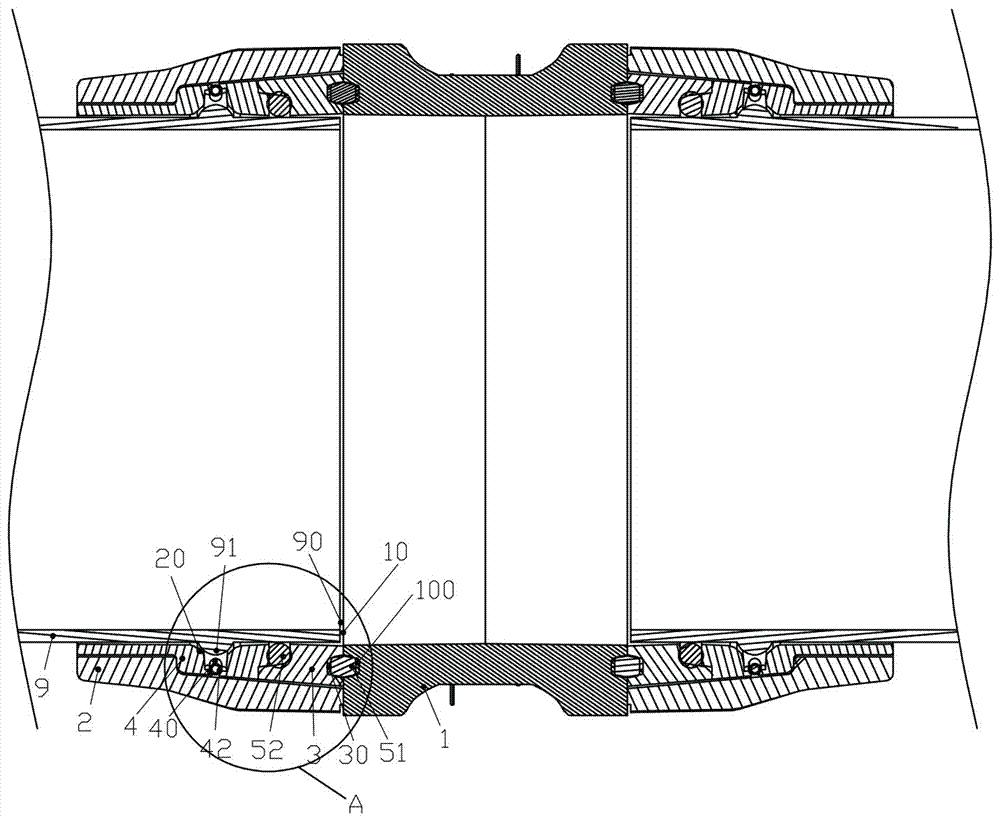

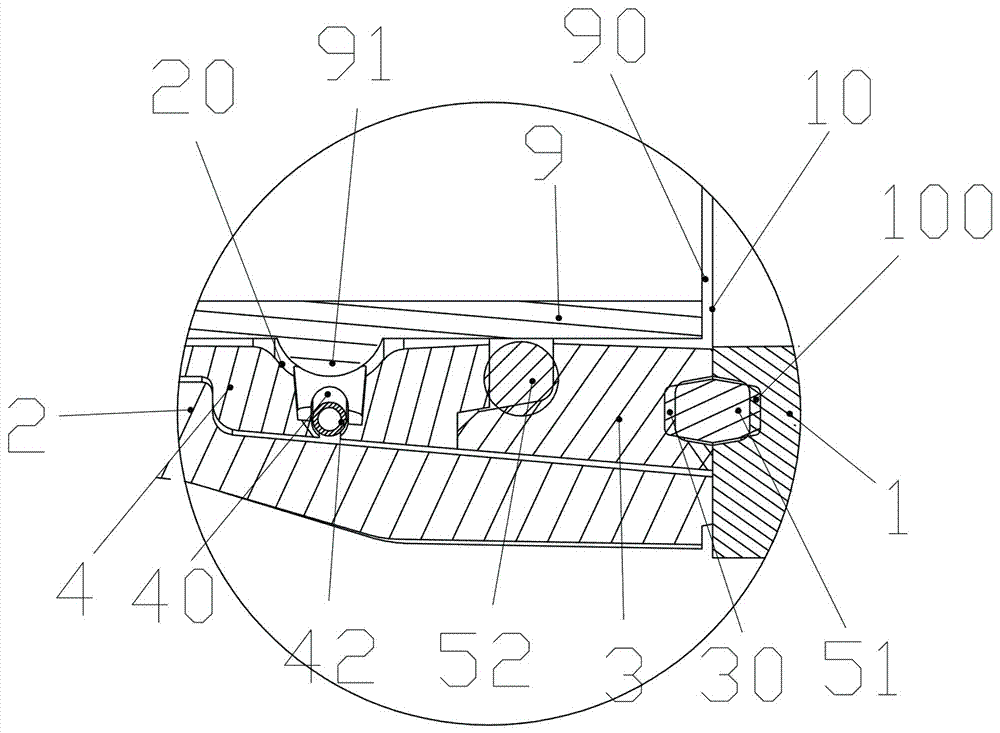

Pipeline rapid connector easy to dismount and mount

A quick connection and connector technology, applied in the direction of pipes/pipe joints/fittings, elbows, pipes, etc., can solve problems such as troublesome, time-consuming, and high costs, and achieve the effect of easy use and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

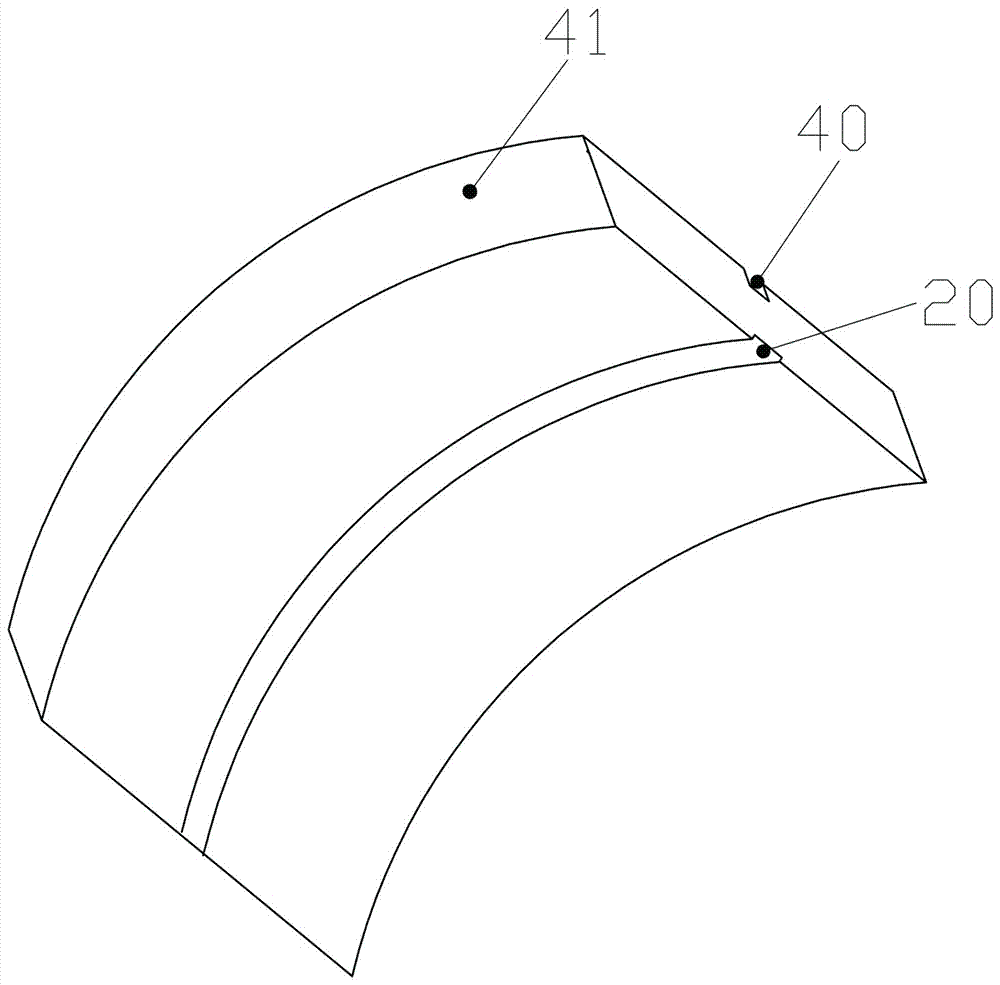

Method used

Image

Examples

Embodiment approach

[0026] In the present invention, in addition to the straight-through connector body, the connector body 1 may also be an elbow connector body or a three-way connector body. Figure 5 Shown is the second embodiment of the present invention, that is, the connector body 1 is an elbow connector body, Image 6 Shown is the third embodiment of the present invention, that is, the connector body 1 is a three-way connector body.

[0027] The present invention can also be set as the fourth embodiment (such as Figure 7 (Shown), the fourth embodiment is substantially the same as the first embodiment, except that the straight-through connector has a variable diameter, that is, the diameters of the two pipes connected by the straight-through connector are different. In this way, the present invention can be applied to more occasions and the application range is wider. Similarly, it can also be a reduced-diameter elbow connector body, a three-way connector body, such as Picture 8 with Picture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com