Spring retractable door

A spring type and pull plate technology, which is applied in the direction of door leaves, windows/doors, door/window accessories, etc., can solve problems such as the inability to open the door and affect escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

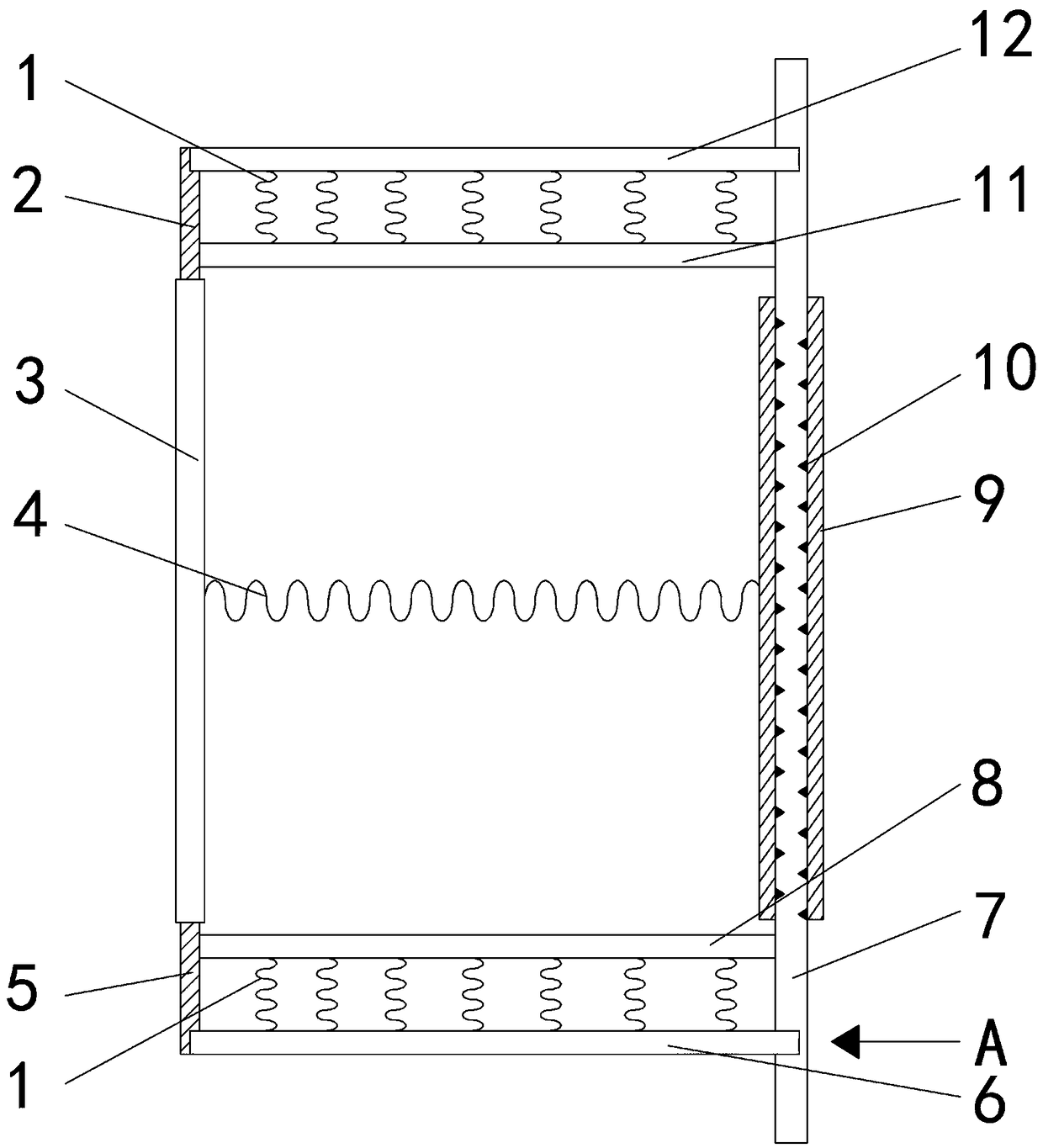

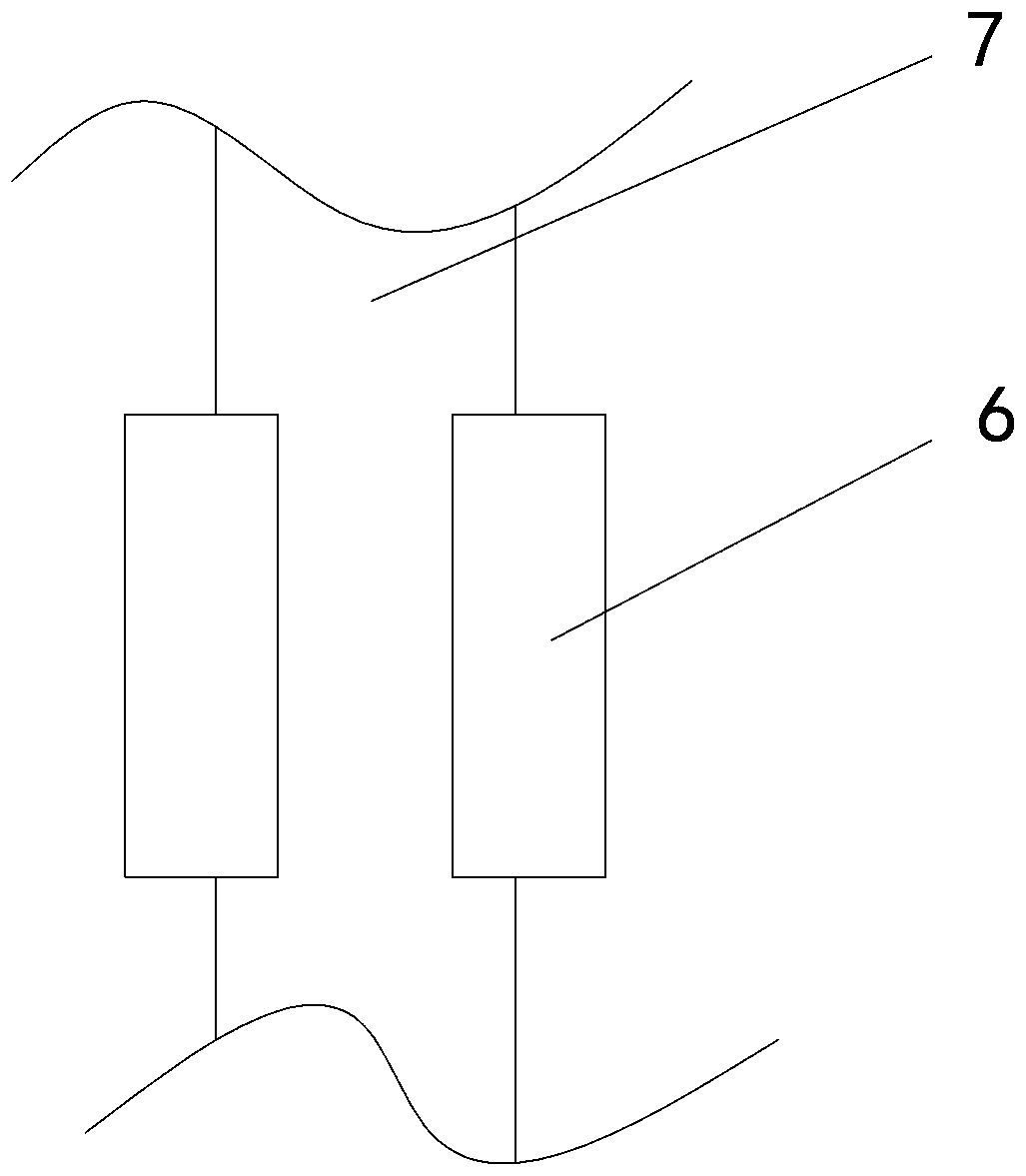

[0016] The reference signs in the accompanying drawings of the specification include: the first tension spring 1, the first contact piece 2, the door post 3, the second tension spring 4, the second contact piece 5, the fourth pull plate 6, the door shaft 7, the third Pulling plate 8, heat insulation cover 9, coolant 10, second pulling plate 11, first pulling plate 12.

[0017] Embodiment: The extension spring type retractable door in this scheme includes a door post 3, a door shaft 7, a first pull plate 12, a second pull plate 11, a third pull plate 8 and a fourth pull plate 6, the first pull plate The plate 12 is equal to the fourth pull plate 6, the second pull plate 11 is equal to the third pull plate 8, the second pull plate 11 and the third pull plate 8 are located between the door post 3 and the door shaft 7, and the second pull plate 11 and the third pull plate 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com