Escape device for tunnel fire disaster

An escape device and fire technology, which can be applied to visible signal devices, mine/tunnel ventilation, signal devices, etc., and can solve problems such as threatening people's lives, health and safety, inhaling a lot of smoke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

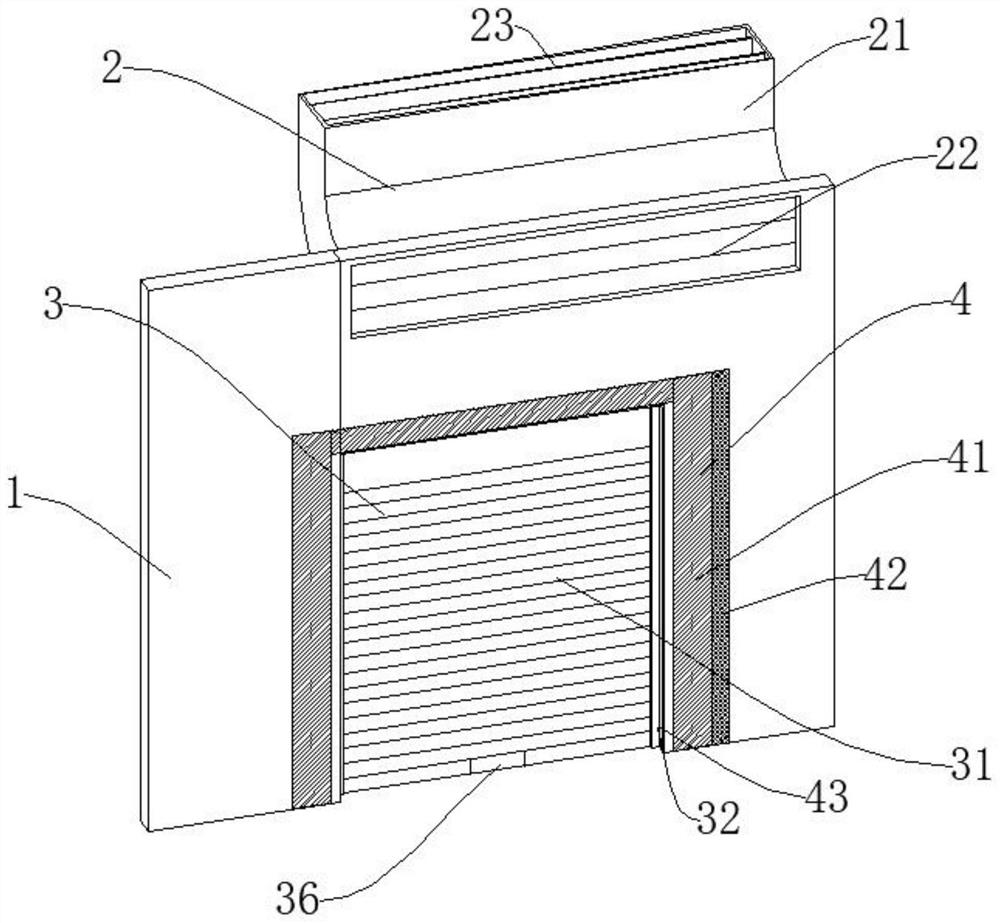

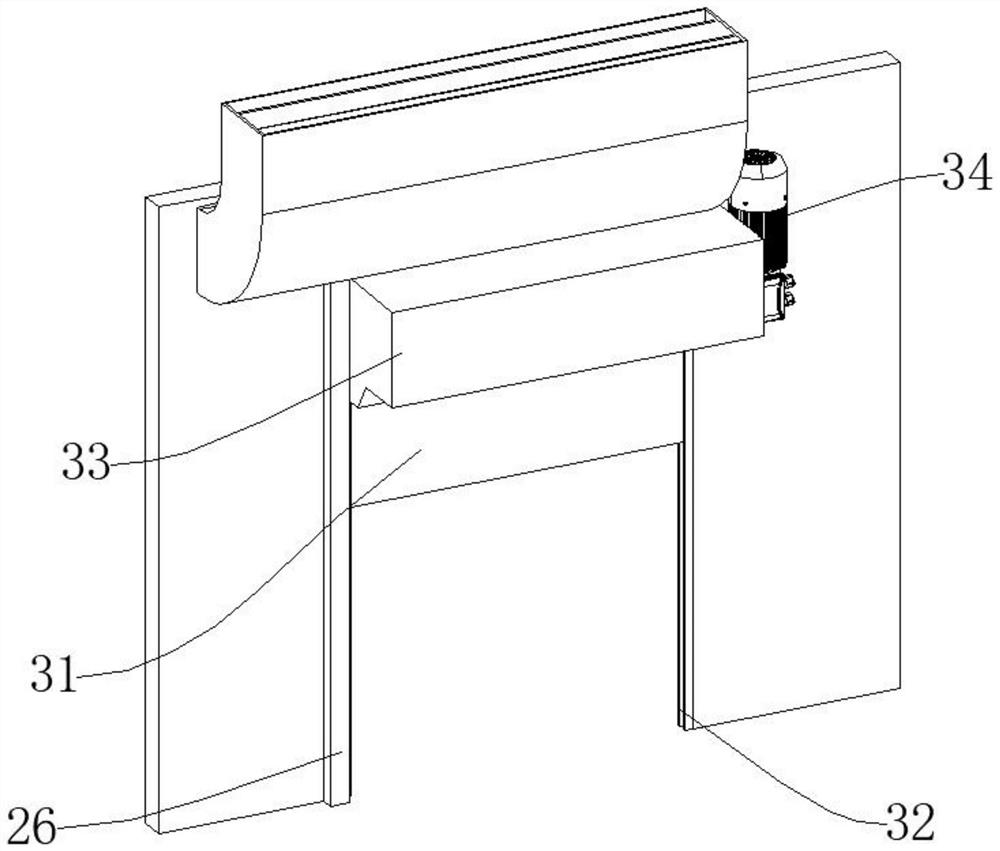

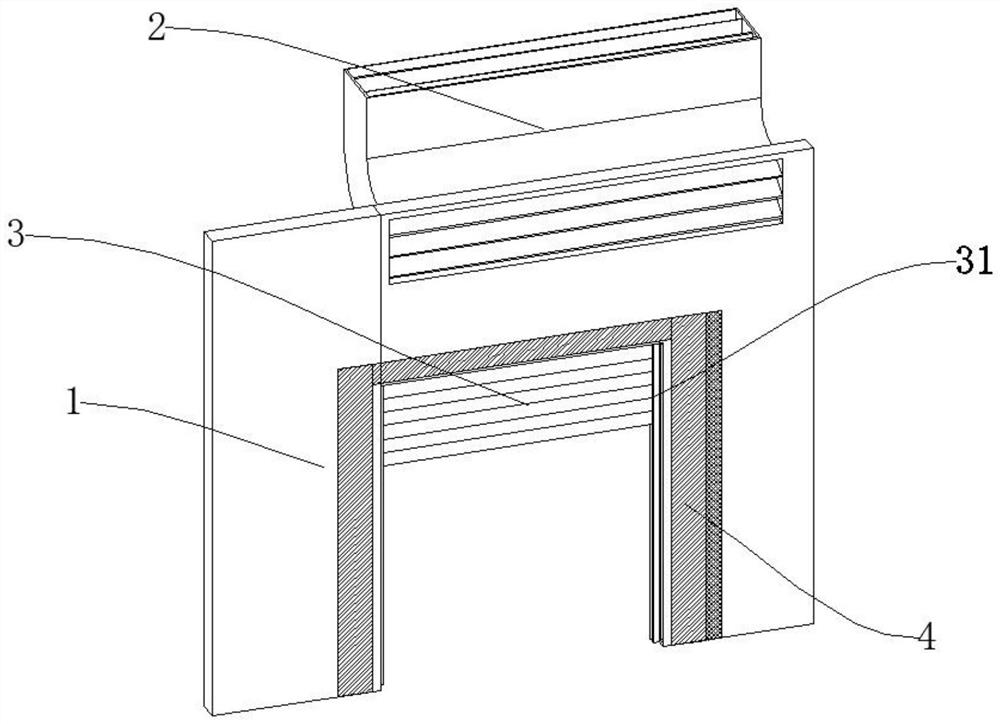

[0048] Such as Figure 1-7As shown, an escape device for tunnel fire disasters, including a one-way smoke exhaust mechanism 2 and a sealing mechanism 3 for preventing the intrusion of dense smoke, a firewall 1 for fixed installation, and an adjustment mechanism 5 for controlling opening and closing And a detection mechanism 4 for detecting the movement of dense smoke. A sealing mechanism 3 is installed on the firewall 1. A one-way smoke exhaust mechanism 2 is arranged on the upper side of the sealing mechanism 3. A detection mechanism 4 is arranged on both sides of the front end of the sealing mechanism 3. One-way exhaust An adjustment mechanism 5 is installed on the smoke mechanism 2;

[0049] The one-way smoke exhaust mechanism 2 includes a smoke exhaust pipe 21, an opening and closing plate 22, a one-way plate 23, and a ratchet group 24; an opening and closing plate 22 is arranged between the front end of the smoke exhaust pipe 21 and the firewall 1, and a one-way opening a...

Embodiment 2

[0054] Such as Figure 8 , the difference between this embodiment and embodiment 1 is:

[0055] The adjustment mechanism 5 includes an adjustment motor 51, a passive bevel gear 511, an active bevel gear 512, and a connecting rod 513; the adjustment shaft 25 is connected with a passive bevel gear 511, one end of the passive bevel gear 511 is connected with an active bevel gear 512, and three active bevel gears 512 Connected by connecting rod 513, one end of the lowermost adjustment shaft 25 is connected to the adjusting motor 51. When the angle and opening and closing of the opening and closing plate 22 need to be adjusted, the control and adjusting motor 51 drives the active bevel gear 512 through the connecting rod 513 to cooperate with the passive bevel gear 511 and adjust shaft 25, so that the opening and closing plate 22 can be opened and closed; the passive bevel gear 511 is keyed to the adjustment shaft 25, the passive bevel gear 511 and the driving bevel gear 512 mesh, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com